| Laser Tire Marking, 4JET Technologies Tire industry under pressure: New tire marking required ahead of schedule

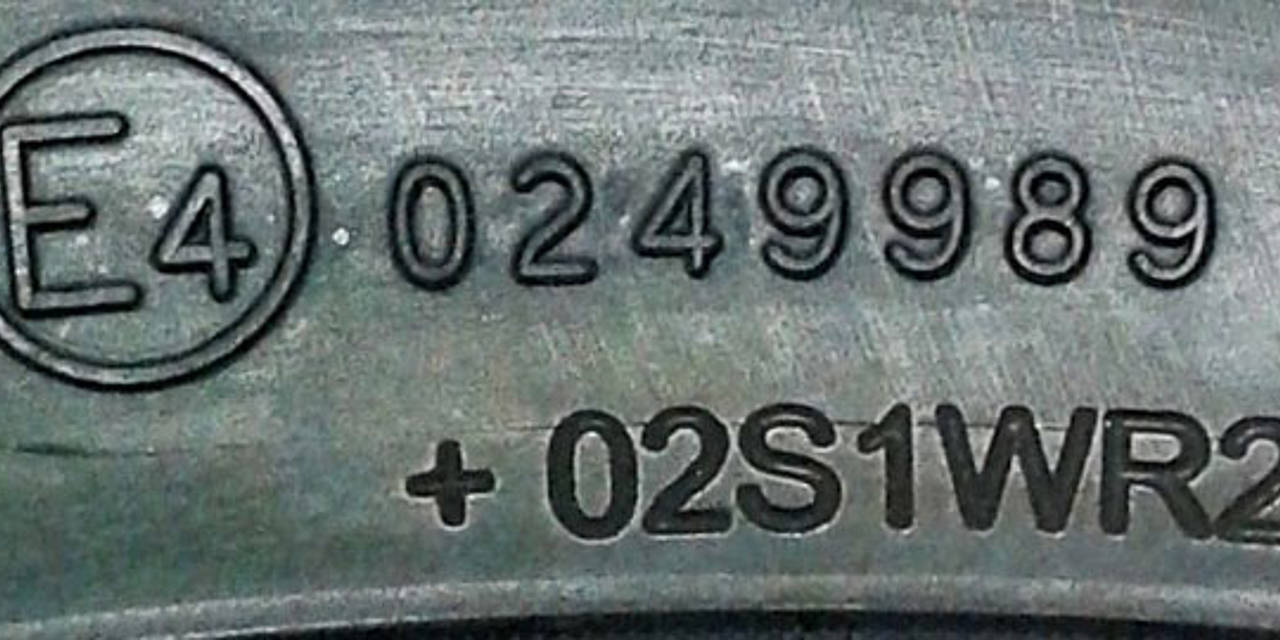

Tire sidewalls carry a multitude of markings, some of which are mandated by law. According to the 2nd revision of the UN/ECE Regulation no. 117 from September 2011 new passenger tires have to be approved for sound emissions, rolling resistance and wet surface adhesion, prompting an additional marking on the tire sidewall. Additionally the EU has introduced similar stipulations for new vehicles with the EC regulation No 661/2009.

While the legally granted implementation phase of the amended regulations is still fairly relaxed, several automotive OEMs now request tires to be compliant ahead of schedule and much sooner than expected. First OEMs do not accept non-compliant tires any more already by now and put tire manufactures under additional implementation pressure. Accordingly the industry now faces the challenge of implementing additional or updated markings on tire sidewalls as early as possible.

Adding markings on a tire typically requires to engrave the mold sidewall. However, specialized mold manufactures are currently overwhelmed by the volume of rework. Furthermore, taking molds out of production for reworking the engraving can create expensive bottlenecks.

Even more critical is the fact that millions of tires with outdated markings are already in warehouses and require to be marked on site or else might be no longer sellable.

4JET laser marking systems answer the imminent need to add information on a tire sidewall, be it during the manufacturing process in the tire factory or in warehouses. “We have received numerous inquiries and purchase orders in recent months” comments Judith Harhues, Key Account Manager at 4JET Technologies GmbH. “Customers calculate against loss of production or even scrapping tires. The business case for the investment is very simple.”

4JET offers a range of laser systems for the tire industry. The T-Mark Compact system is a mobile laser based tire marking device. In semi-automated operation it can mark between 500 to 1,000 tires per day. 4JET also offers fully automated T-Mark systems for high volume new tire production.

Besides emergency marking cases as the new ECE codes, it has a broad range of applications, such as country specific markings for low volume tires or serial number marking for test and development tires. Furthermore all T-Mark systems are now equipped with 4JETs SCANNECT® solution for smart phone readable QR coding of black tires.