| Photovoltaic & Glass, 4JET microtech 4JET launches GDSflex – Cost efficient and flexible via drilling for solar module glass

Leading glass manufacturer orders more GDSflex machines 4JET

4JET Technologies GmbH has launched a new product for drilling via holes in glass substrates for c-Si photovoltaic modules. Several of the new systems have been ordered by a major glass supplier in Asia.

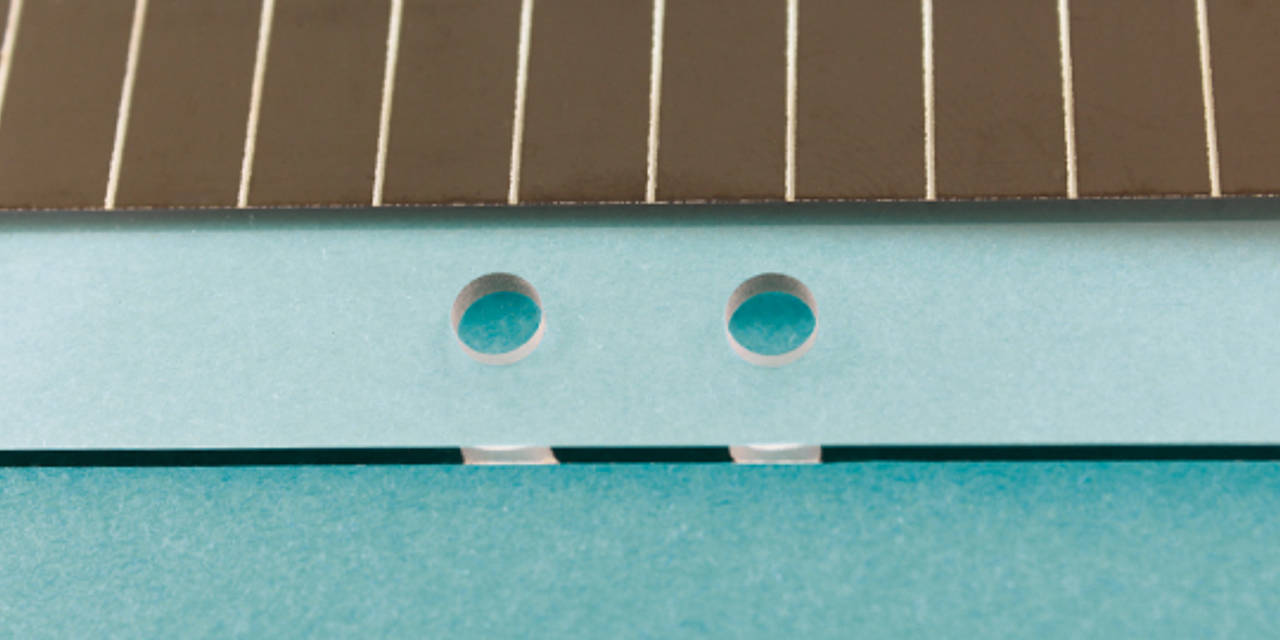

The increasing use of glass/glass modules in PV applications requires to create holes for bus bar wires and junction boxes in cover or substrate glass sheets. Depending on the module design, several holes in different locations of a sheet may be required.

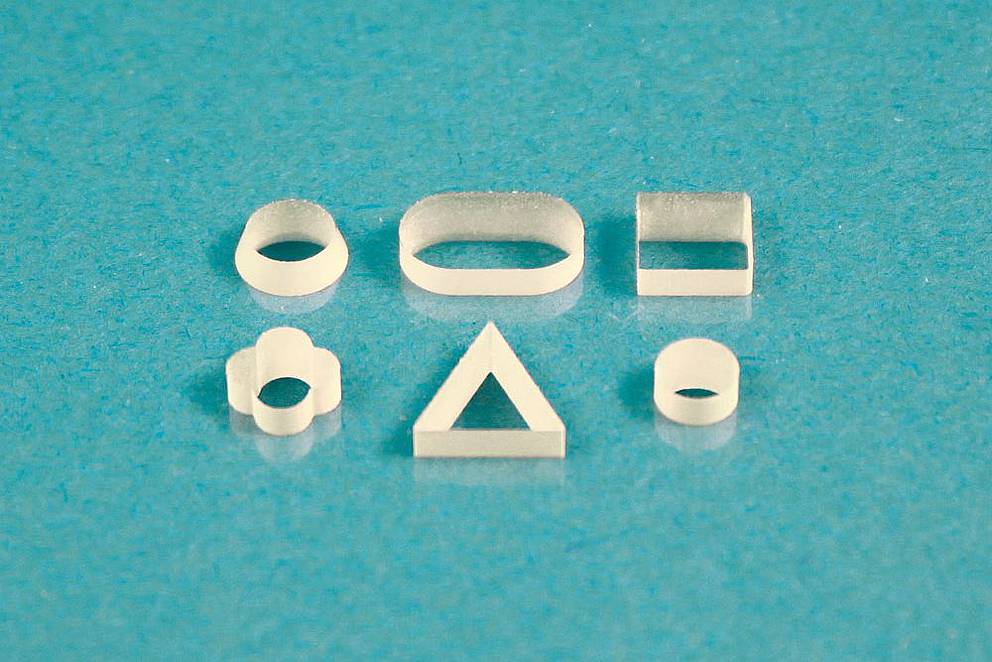

The new GDSflex systems allow inline processing of glass panels in a fully automated and highly flexible setup: Holes of different diameters can be positioned in any quantity anywhere on the glass sheet without retooling. The machine is designed to work with typical glass module sizes and thicknesses.

Other than conventional mechanical processes, laser drilling provides for a touchless and dry process. Post processing of the hole edges is not required. Regular float and semi-tempered glass can be processed with the 4JET system.

Besides applications in PV, the GDSflex is also well suited to drill holes in glass sheets for glazing and automotive applications. 4JET is also offering solutions for high precision drilling and cutting of chemically strengthened glass in the display manufacturing industry.