Thin-Film Photovoltaics

Laser Micromachining for High-Efficiency Thin-Film Photovoltaics

We provide scalable laser systems for scribing, edge deletion, and precision patterning of thin-film solar materials – including perovskite, CIGS, CdTe, and tandem cells – for next-generation module efficiency and durability.

Laser-Driven Innovation in Next Generation Thin-Film Solar

Thin-film photovoltaic (TFPV) technologies are reshaping solar manufacturing with lightweight, flexible, and cost-effective alternatives to crystalline silicon. To maximize performance and reduce dead zones, these advanced solar stacks demand laser micromachining solutions that are precise, non-destructive, and contamination-free.

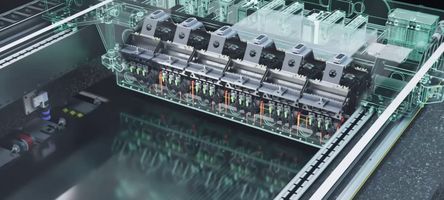

We deliver proven laser tools for P1–P3 scribing, edge deletion, and multilayer patterning – enabling seamless module interconnection, yield optimization, and long-term reliability. Our contactless processes are suitable for rigid and flexible modules, including roll-to-roll platforms.

Whether for R&D, pilot lines, or multi-GW production, we empower the solar industry to scale next-gen photovoltaics with unmatched accuracy and throughput.

Key Technical Features for Thin-Film Photovoltaics Processing:

Key Applications & Our Capabilities

P1, P2, and P3 Laser Scribing of Thin-Film PV Cells for Monolithic InterconnectionDead Zone Reduction & Line ParallelismEdge Deletion for Moisture Protection & Electrical IsolationLaser Patterning for Interconnects and Custom Cell DesignsSelective Coating Removal and Layer IsolationSurface Cleaning and Pre-Bond PreparationFlexible and Tandem PV Module CompatibilityInline Monitoring & Process Control

P1, P2, and P3 Laser Scribing of Thin-Film PV Cells for Monolithic Interconnection

Applications:

- P1 (substrate isolation), P2 (interconnect), and P3 (top contact removal)

- Used in CdTe, CIGS, and perovskite thin-film cells – rigid or flexible formats

4JET Technology Fit:

- Ultrashort pulse laser scribing with minimal heat-affected zones and layer-selective control

4JET Solution:

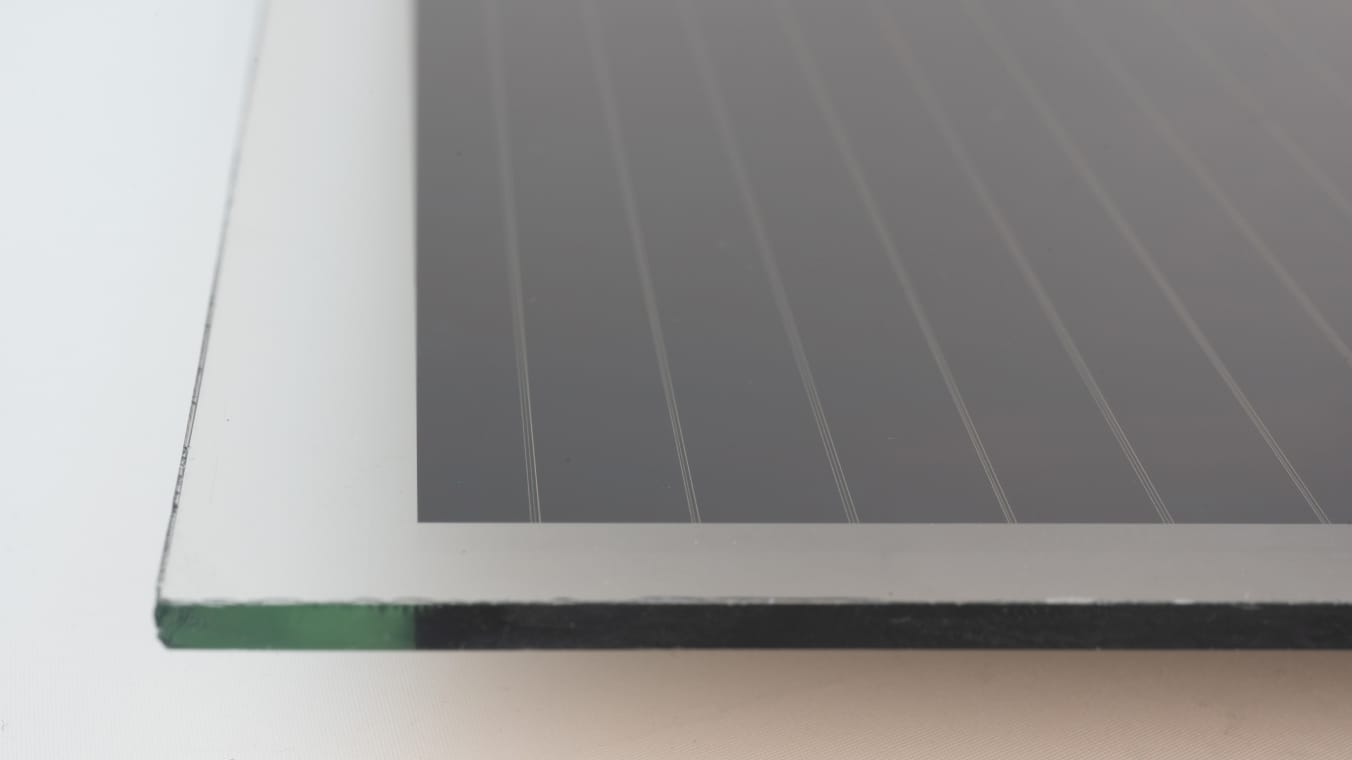

- Delamination-free, layer-specific scribe lines with controlled width and depth – minimizing dead zones and maximizing active cell efficiency

4JET Platform:

Dead Zone Reduction & Line Parallelism

Applications:

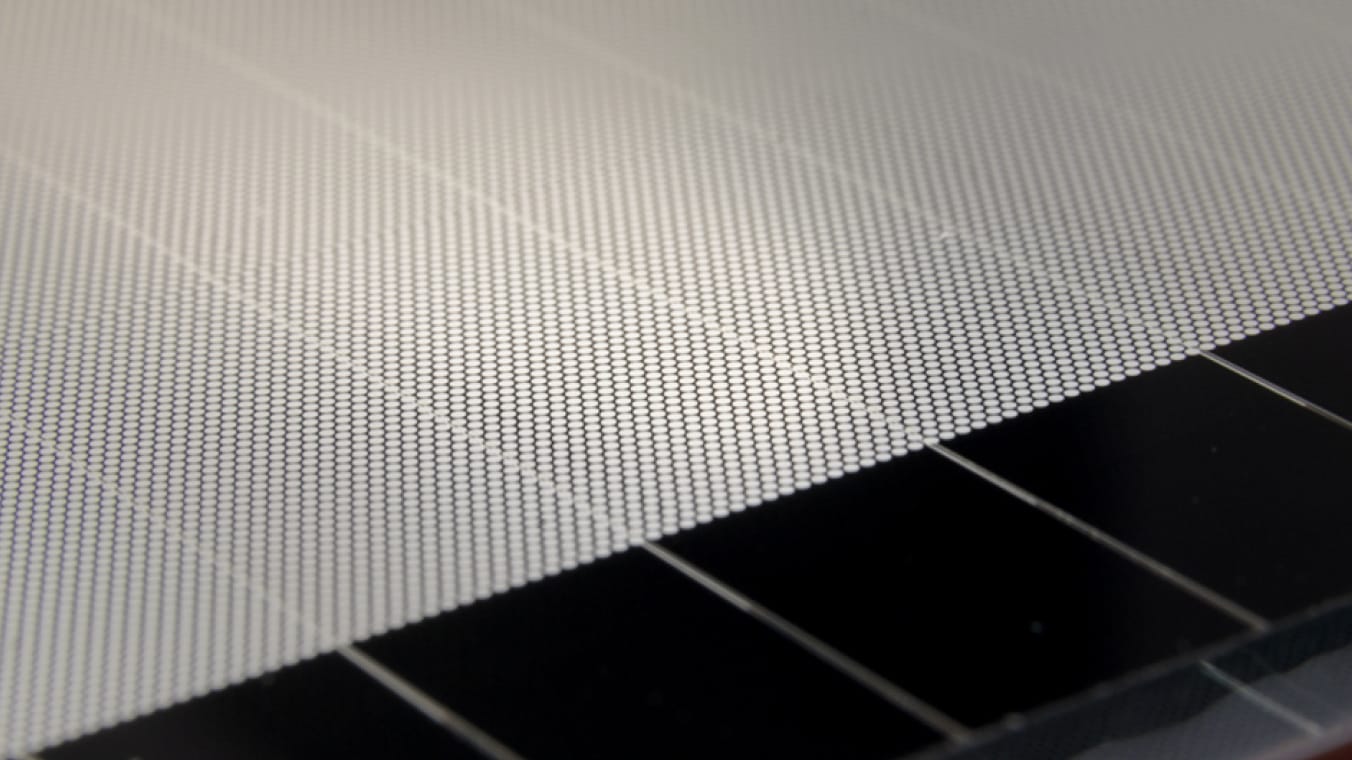

- Reducing inactive zones between cells

- Improving power density and yield through tight scribe tolerances

4JET Technology Fit:

- Precision scan systems with inline vision and beam control

4JET Solution:

- Real-time correction and sub-micron alignment for consistent scribing uniformity

4JET Platform:

Edge Deletion for Moisture Protection & Electrical Isolation

Applications:

- Removal of conductive layers (TCOs, metals) from module edges

- Preparing sealing zones for lamination and encapsulation

4JET Technology Fit:

- High-power scanning ablation for multilayer coating stacks

4JET Solution:

- Uniform, residue-free edges with no substrate damage – ready for sealing and bonding – ensuring stable encapsulation and long-term module performance

4JET Platform:

Laser Patterning for Interconnects and Custom Cell Designs

Applications:

- Patterning for shingled cells, bypass zones, or custom layouts

- Functional segmentation for semi-transparent or flexible mod

4JET Technology Fit:

- Digitally defined ablation paths with adaptive focus

4JET Solution:

- Custom scribe geometries and dynamic process adjustment

Selective Coating Removal and Layer Isolation

Applications:

- Ablation of ITO, silver, TCO, or barrier layers in tandem or hybrid cells

- Precision removal without damaging active material layers

4JET Technology Fit:

- Maskless, software-defined patterning and layer isolation for multilayer structures

4JET Solution:

- Sharp, crosstalk-free removal of functional coatings – compatible with perovskite and hybrid cells

4JET Platform:

Surface Cleaning and Pre-Bond Preparation

Applications:

- Pre-lamination or pre-print cleaning of module surfaces

- Removal of micro-particles, oxides, or process residues

4JET Technology Fit:

- Laser cleaning with tunable pulse and energy settings

4JET Solution:

- Dry, contactless surface conditioning to ensure bonding integrity

Flexible and Tandem PV Module Compatibility

Applications:

- Integration with roll-to-roll lines, tandem perovskite-silicon architectures

- Processing of PET, ultra-thin glass, or metal foil substrates

4JET Technology Fit:

- Modular beam handling and substrate alignment for curved or flexible formats

4JET Solution:

- Compact, modular, and scalable platforms for both pilot and high-volume manufacturing

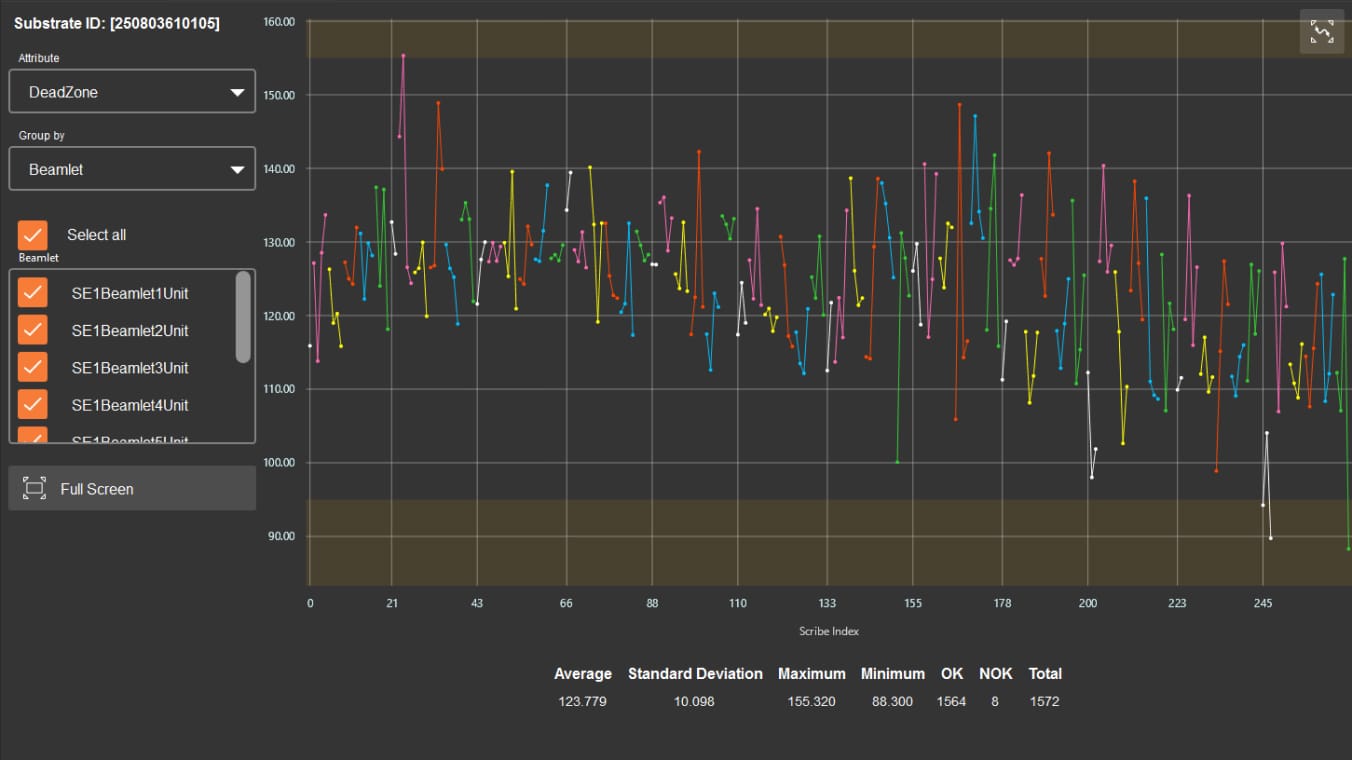

Inline Monitoring & Process Control

Applications:

- Inspection of scribe width, layer removal, and defect detection

- Yield control in mass production environments

4JET Technology Fit:

- Integrated metrology and closed-loop control modules

4JET Solution:

- MES (Manufacturing Execution System)-compatible process data capture and smart manufacturing readiness

Why 4JET?

Proven performance in perovskite, CIGS, CdTe, and hybrid cell stacks

Trusted by R&D centers and large-scale solar module manufacturers worldwide

Tailored tools for sheet-fed, glass-glass, and roll-to-roll architectures

Compact, low-maintenance platforms supporting rapid technology transitions

Driving Innovation in Thin-Film PV?

Let’s discuss how we can support your perovskite or thin-film PV roadmap – from feasibility testing to automated production.

Enabling Capabilities Across All Thin-Film PV Applications

The thin-film photovoltaics industry demands large-area precision, uptime-focused automation, and scalable process control. 4JET’s laser systems are engineered to meet the unique material and process challenges of TFPV manufacturing – across all major technologies like CIGS, CdTe, and perovskites.

Core4 Software Platform Global Services & SupportAutomation Integration

Core4 Software Platform

At the heart of every 4JET machine, Core4 ensures consistent performance and optimized throughput for PV production lines.

- Modular and scalable software architecture for roll-to-roll and sheet-based systems

- Seamless integration of laser controls, machine vision, and PLCs

- AI-powered vision tools for real-time tracking of scribe quality and layer alignment

- Backed by a 20+ developer team ensuring fast iteration, updates, and field support

Global Services & Support

Global team to support uptime and line efficiency in 24/7 manufacturing environments:

- Remote diagnostics, live software assistance, and recipe tuning

- On-site installation, training, and maintenance support

- Long-term service contracts to ensure productivity and process stability

Driving Innovation in Thin-Film PV?

Let’s discuss how we can support your perovskite or thin-film PV roadmap – from feasibility testing to automated production.