Our focus is the use of pulsed laser radiation for ablation or modification of surfaces. Hundreds of 4JET laser systems have now processed billions of components. Our applications:

Silent Tires

In the innovative LASER-FIT process, a tailor-made acoustic foam is produced directly inside the tire from liquid starting materials. This method eliminates the just-in-sequence complexity, time-consuming logistics and manual process steps, while also giving the tire manufacturer greater freedom in adapting geometry and volume of the foam.

Laser Cleaning & Laser Surface Preparation

As pioneers of the technology, we offer solutions for gentle, precise cleaning and preparation of technical surfaces. By using pulsed laser radiation, organic layers or oxides can be removed and metals can be prepared for subsequent contacting or bonding precisely and without the use of chemical solvents. Applications also include cleaning, for example of molding tools in rubber, tire and plastics industries, glass production or thermoforming. Today, lasers are also used for rust removal, preparation of non-destructive tests, decontamination, or cleaning stone surfaces in restoration or fire cleanup.

Laser Paint Stripping & Laser Coating Removal

Cathodic dip coatings, polyurethane paints, polyamide and other coatings can be removed dry, residue-free, and precisely with the 4JET process. The laser replaces the time-consuming masking of components and the use of environmentally harmful solvents. The advantages of dry processing are found in higher process yields, lower process costs and a significantly improved environmental balance.

Laser Patterning

Thin conductive layers can be precisely patterned with small feature sizes using laser ablation. For applications in photovoltaics, automotive or architectural glass processing our systems deliver highly productive solutions – including the ablation of TCO layers, low-E coatings, semiconductors and metal films. We push the limits of what is technically feasible with productivity rates unmatched in the industry through innovative scan concepts such as our 3D remote process or "on-the-fly" processing with up to 5 galvo heads working in parallel.

Laser Cutting

By using ultrashort pulsed lasers, transparent materials can be modified. This principle is the basis of our PearlCut technology for laser filament cutting of glass. The superior solution for flexible free-form cutting of soda lime, borosilicate and chemically strengthened glasses replaces multi-step mechanical processing and its disadvantages such as scrap, edge chipping and the use of wet auxiliary media.

Surface Functionalization with Laser

We are pioneers in the large-area modification of surfaces. By using lasers it is possible to modify adhesion, friction, flow resistance or haptics of surfaces in a targeted manner. With our LEAF process based on the principle of laser interference patterning, we have set the global benchmark for the economical production of functional surfaces.

Laser Marking

Tire rubber can be precisely marked or structured with laser radiation. Both continuous wave and pulsed lasers are used. Applications include the application of matrix codes, clear text or graphics, as well as the carving of profiles in tire prototypes.

Wheel & Tire Inspection

We do not just use lasers as a processing tool - we also have extensive knowledge of laser based machine vision, image capture and processing. For the tire industry, we develop solutions for the final inspection of products or product identification as in the reading of DOT week codes.

Learn more

TIS – Wheel & Tire Inspection Product Line

Laser Tire Uniformity Correction

Selective, precise and traceless laser ablation of material from a tire´s bead area allows to improve the tire uniformity parameters. Ablation area and patterns are automatically generated based on the tire´s TU data. Other than mechanical grinding the process works clean, without tool wear and the resulting surface is smooth. The technology has seen significant industrial adaption in the last years under an exclusive supply agreement and is now commercially available to any tire manufacturer.

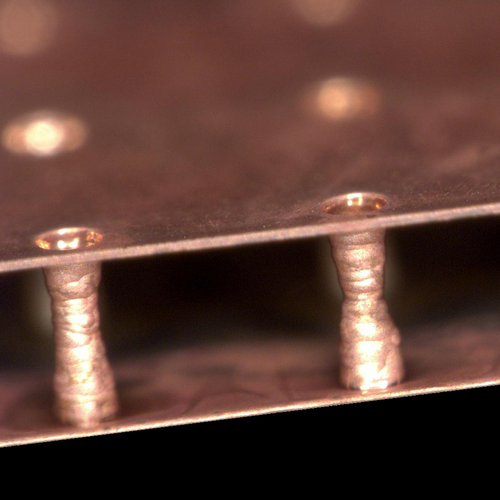

Glass volume structuring with VLIS

Our technology for the production of through-glass-vias developed together with Plan Optik AG, enables the production of metallized through-hole contacts in glass semiconductor rates. Application areas include advanced packaging, display industry, glass-based MEMS, microfluidics or high-frequency antenna technology (e.g. 6G).