TOPAZ LED

PRECISION AND EFFICIENCY IN PV MODULE EDGE DELETION

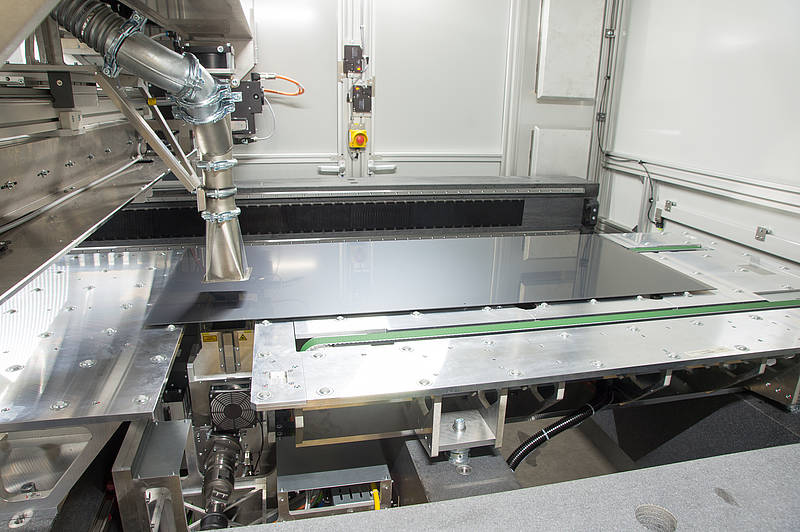

The TOPAZ LED is equipped with a variety of innovative components that are part of an optimized system that maximizes precision and efficiency in the edge deletion of PV modules. The belt conveyors were developed specifically for glass transport and the LED process and are characterized not only by their cost efficiency, in that complex and expensive linear grippers can be dispensed with entirely. They are also characterized by the achievable speeds, the robustness, and the associated highest possible uptime of the machine.

Granite for long-term Stability and Accuracy

A key advantage of the TOPAZ LED is the use of granite in its structure, which ensures high temperature stability and eliminates vibrations, resulting in the highest precision. The processing head, which is the heart of the machine, is moved by a high-precision linear axis and has an impressive sensor system for edge detection and tracking, also achieving the highest processing accuracies. In addition, an autofocus system is also implemented, through which inaccuracies of the substrate are compensated and thus consistently excellent results are achieved around the entire circumference of the substrate. The optical design of the processing head with the integration of fiber-coupled lasers offers flexibility, minimum maintenance time and precision even at high processing speeds to ensure optimal edge deletion.

The Topaz LED is the result of all the experience we have gained as the unmatched leader in laser edge deletion since 2006. It is a high-quality yet cost-effective solution for the efficient production of thin-film PV modules and continues the success.

Specification

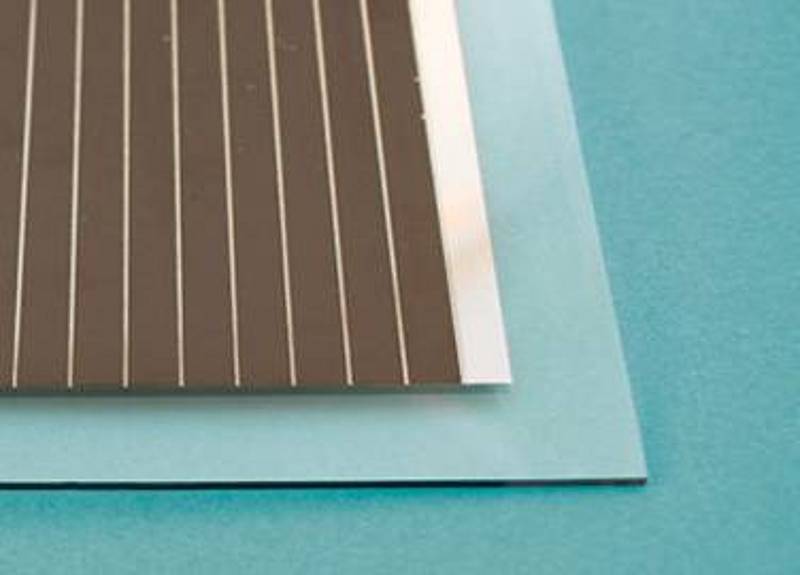

| Process | Laser Edge Deletion (LED) typically through the glass lift-off process. Film side processing on request. |

| Thin film materials | PV layers stacks such as CdTe, Perovskite and CIGS |

| Laser sources | High power nanosecond laser |

| Patterning resolution | Square spots with approx. 1mm²; others on request |

| Scanning | On-the-fly with up to two processing heads |

| Working area (x, y) | Up to 2.400 mm x 1.300 mm; other upon request |

| Substrate dimensions | Customer specific within machine working area specification |

| Glass thickness | 2 mm up to 4 mm, others on request |

| Position accuracy | +/- 200 µm relative to the glass edge |

| Particle extraction | High volume flow, high pressure, high efficiency filtering |

Contact

We look forward to your questions – our experts are at your disposal.