Laser edge deletion in thin-film photovoltaic module production

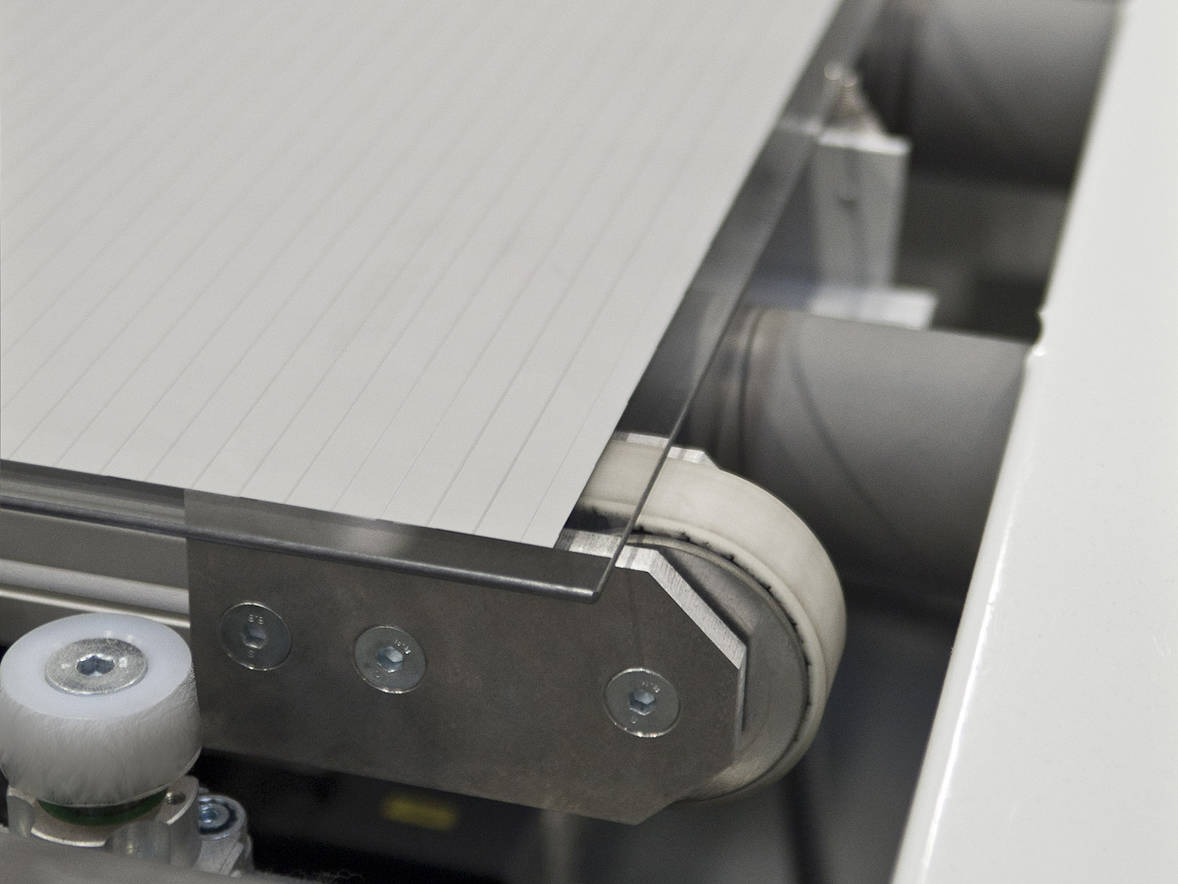

Laser edge deletion (LED) based on large-focus laser ablation effectively prepares thin-film photovoltaic modules for subsequent hermetic sealing to ensure the modules' longevity. 4JETs TOPAZ LED achieves high ablation rates of up to 80 cm²/s with on-the-fly scanning for highest throughput.

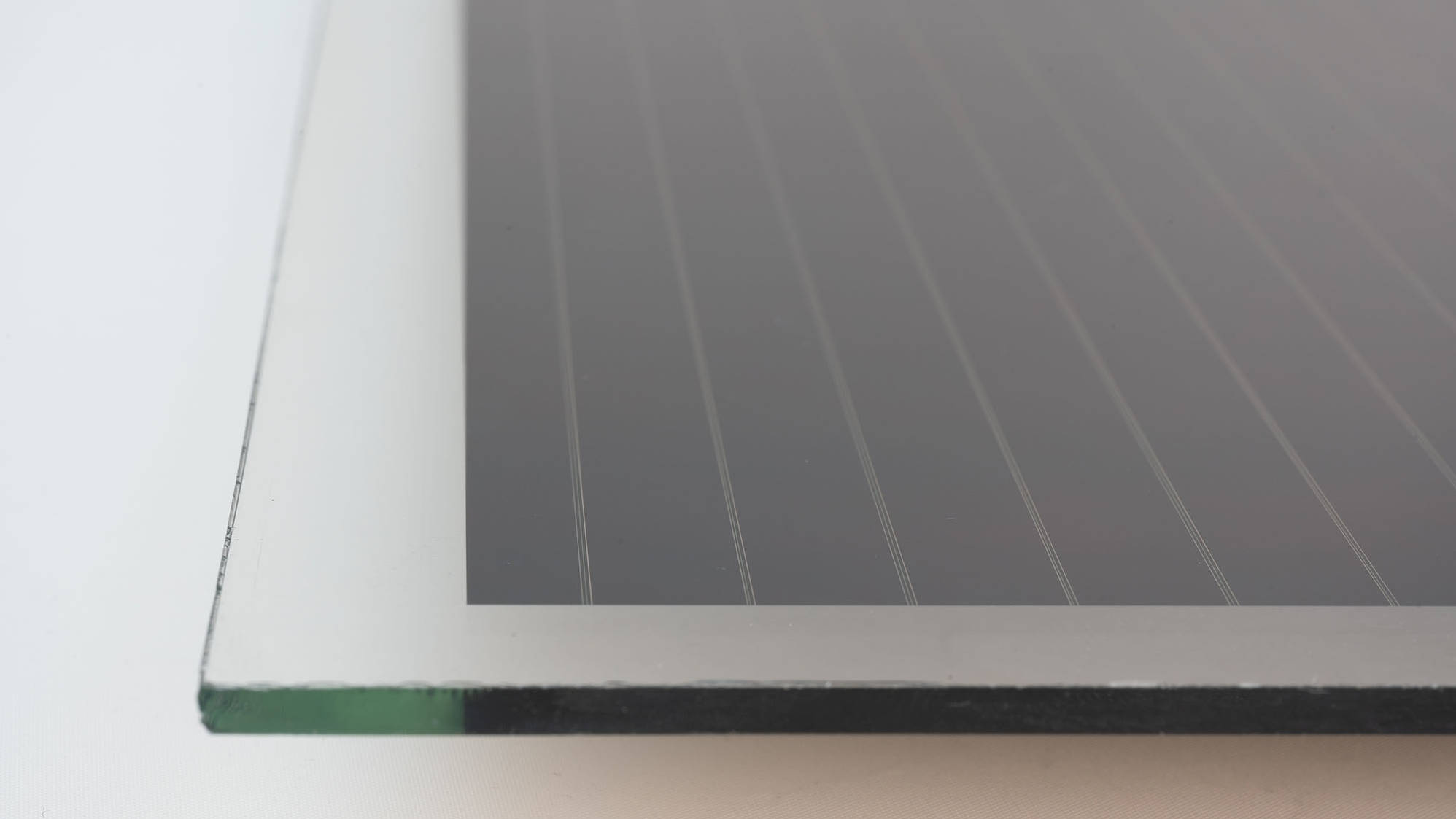

A clean and undamaged glass surface in the edge area of thin-film photovoltaic modules, produced by means of laser edge deletion (LED) from 4JET, is an essential prerequisite for durable thin-film modules. The clean glass surface at the edge of the thin-film solar module protects the active layers of the module from environmental influences, acts as a barrier against moisture and steam and thus ensures reliable modules. The contactless laser edge deletion has completely replaced the aggressive mechanical sandblasting or grinding processes.

4JET's solution for the perfect thin-film solar module

Meet our highly-accurate TOPAZ LED tool – designed to produce reliable long-lifetime thin-film modules at low production costs!

Contact

We look forward to your questions – our experts are at your disposal.