Laser Cutting

Creating the Perfect Glass Edge

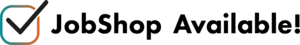

What is a filament? When an ultrashort laser pulse is very strongly focused into a transparent medium such as air or glass, nonlinear absorption effects lead to a self-generated focusing lens. This is comparable to placing a lens in the transparent medium, which further focuses the laser pulse. The high intensity of the laser pulse in the center of the Gaussian intensity distribution compared to the lateral flanks causes the wavefront to travel more slowly in the center, which corresponds to a focusing. This induced change of the refractive index is called optical Kerr effect.

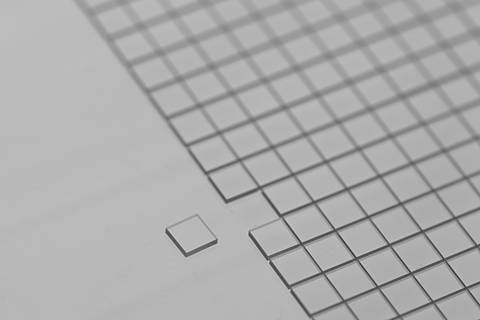

The result of the self-focusing is an intensity high enough to ionize the glass material, which in turn leads to diffraction of the laser pulse. However, the intensity of the laser pulse is still high enough to cause the Kerr effect to occur again. As a result, the laser pulse repeatedly focuses itself along its propagation direction. This series of self-focussing is called a filament. A filament resembles pearls on a string. This is why we call the process PearlCut.

Some practical Considerations

How can glass be separated or cut with the help of a filament? A modification is not sufficient, since it is only a tiny weakening of the glass in a diameter of 1 - 3 µm. So, on the one hand, a filament, i.e. a series of modifications, should be created which completely penetrates the glass thickness. On the other hand, a line of filaments is necessary to form a dividing line in the cutting direction. Therefore the lens has to be moved relative to the glass body.

Automatic Glass Seperation

Where physically feasible, the glass is separated by a subsequent CO2 laser process. The necessary optics can be integrated together with the filament optics in one processing head or, if the cycle time requires it, can be offered in a separate machine. Where CO2 separation is physically impossible due to a too low coefficient of thermal expansion, a standard mechanical breaking process can follow. The glass separation process using a CO2 laser is based on selective heating along the filament line, which creates a temperature gradient perpendicular to the cutting line. This results in tensile stresses in the glass, which lead to separation along the filament line.

CO2 separation works particularly well for glass types with a relatively high coefficient of thermal expansion. Chemically tempered glass separates by itself due to internal residual stress. Thermally toughened glass can be separated if the toughening is low enough.

Advantages of PearlCut

The advantages of applying filament-based glass cutting over conventional mechanical methods like scribe and break are numerous:

- The process does not generate any glass particles or residues, thus avoids a subsequent cleaning step.

- Filament cutting is a dry process without the need to use water. The effect of this may be larger than expected, not only that the water has not to be paid for, in addition no drying has to be applied afterwards and also very important to note, there is no need for a costly water treatment.

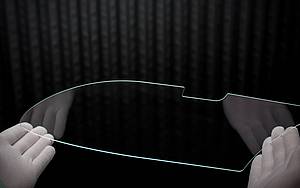

- The absence of chipping or micro-cracking combined with the low edge roughness of Ra < 1 µm provides high edge strength.

- The filaments can be introduced into the material at speeds of up to 1 m/s and above for economic takt times in many applications.

Enhancing your Capabilities

Additional benefits compared to conventional mechanical cutting technologies are:

- Complex cutting geometries are possible, notches etc. can be generated.

- No material loss and no wear of tool means extremely precise dimensional accuracy, constant across large production runs.

- Ultra-thin glass and glass stacks can be cut, even with an offset between the upper and the lower glass.

- Combined with a CO2-laser separation process a full automation is possible, increasing yield and safety.

JobShop - Laser technology as a service

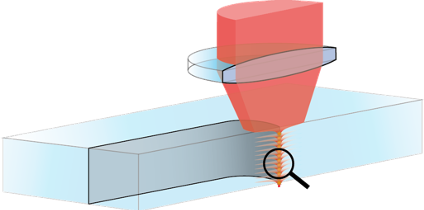

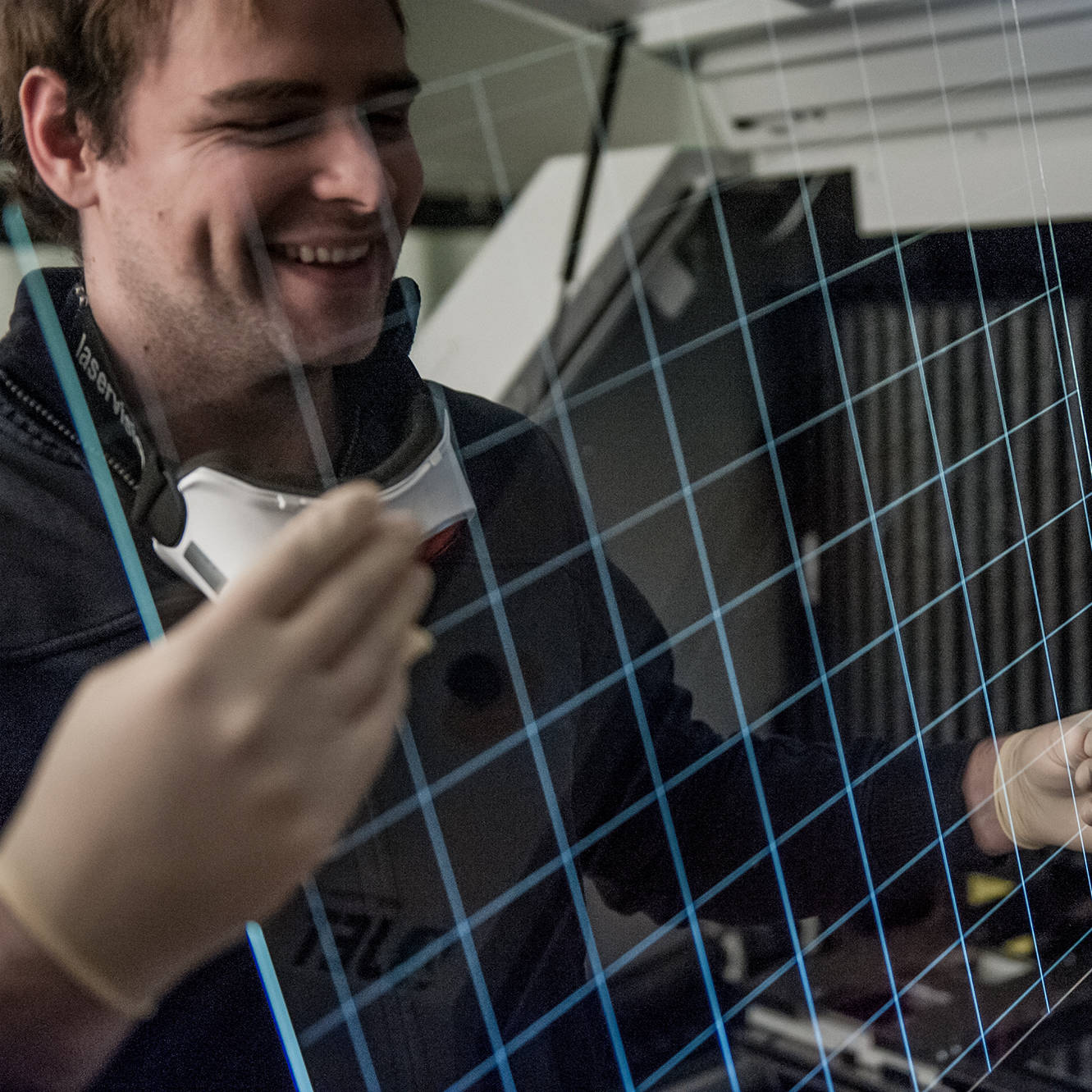

Through our JobShop, we offer you the chance to benefit from 4JET's high-tech equipment for laser cutting of glass without having to make the initial investment for your own laser processing systems. Our MicroFab location in Prutting near Rosenheim not only handles all production steps from initial sampling to 100% quality control, but also the procurement of substrates, cleaning and packaging as well as door-to-door logistics.

If you are interested in perfect glass edges by precision laser systems, here you have the opportunity to gain first experience with the quality of the process without any investment costs.

For more information about our laser processing service, please contact us at any time or visit our JobShop website.

MicroFab - Laser as a service

We cut your glasses

After all PearlCut proves to be an enabling technology for many applications, be it the separation of ultra-thin glass in complex shapes or the cutting of glass stacks for smart window applications

Meet our PEARLs designed for robust, fast and cost-effective laser glass cutting able to create the perfect edge for many industrial applications areas.

Contact

We look forward to your questions – our experts are at your disposal.