Laser Cleaning & Surface Preparation

Welding and bonding preparation for high process reliability

Innovative welding or bonding processes in e.g. automobile manufacturing require perfectly pre-treated surfaces. Depending on the task, release agents and oils must be removed without harming the underlying component or the surface must be prepared with a specific roughness in order to produce a reliable joint. Current surface preparation processes using wet chemicals or abrasive blasting media often require time consuming masking of parts or to expose the entire part to the process - even if only selected areas require processing. This drives up the total process cost and makes cleaning more complex than it needs to be.

In comparison, lasers provide significant advantages that quickly provide pay back of the initial investment:

- Selective cleaning: lasers allow to work precisely where cleaning is needed – without masking

- No post-processing - no demasking, no drying, no blast dust removal

- Dry process: lasers work without any consumable cost for cleaning media and eliminate the need to recycle large amounts of cleaning by products from water or blasting dust

Enabling mixed materials for lightweighting

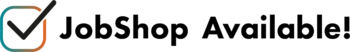

Laser surface preparation enables new technologies: Driving down vehicle emissions by reducing weight is a key challenge in making transportation more sustainable and extending the range of EVs. This requires bonding of new material combinations such as composites, noise insulating foams, ABS plastics or die-cast aluminium. Our laser systems can specifically structure or activate such surfaces by changing their morphology. Depending on the choice of laser fluence (“intensity”) and spot overlap, a defined surface topography can be achieved to create small bowl-shaped cutouts or a grooved structure. A pair of surfaces modified in this way features improved mechanical adhesion.

Driving Electricfication of Cars

The manufacturing and assembly of batteries and battery trays for EV require perfectly clean surfaces: cells need to be cleaned before adhesive bonding to a pack of cells and battery trays require selective laser paint removal of KTL coatings.

Laser surface processing is fast …

Process speed of laser cleaning or surface processing varies with how well the surface absorbs the laser light, the coating thickness and how much laser power is applied. Typical laser cleaning systems work with 100 W to 2kW average laser power and yield cleaning speeds of 10cm²/s to 100cm²/s. In other words: today our most powerful laser cleaning systems can clean square meters per minute!

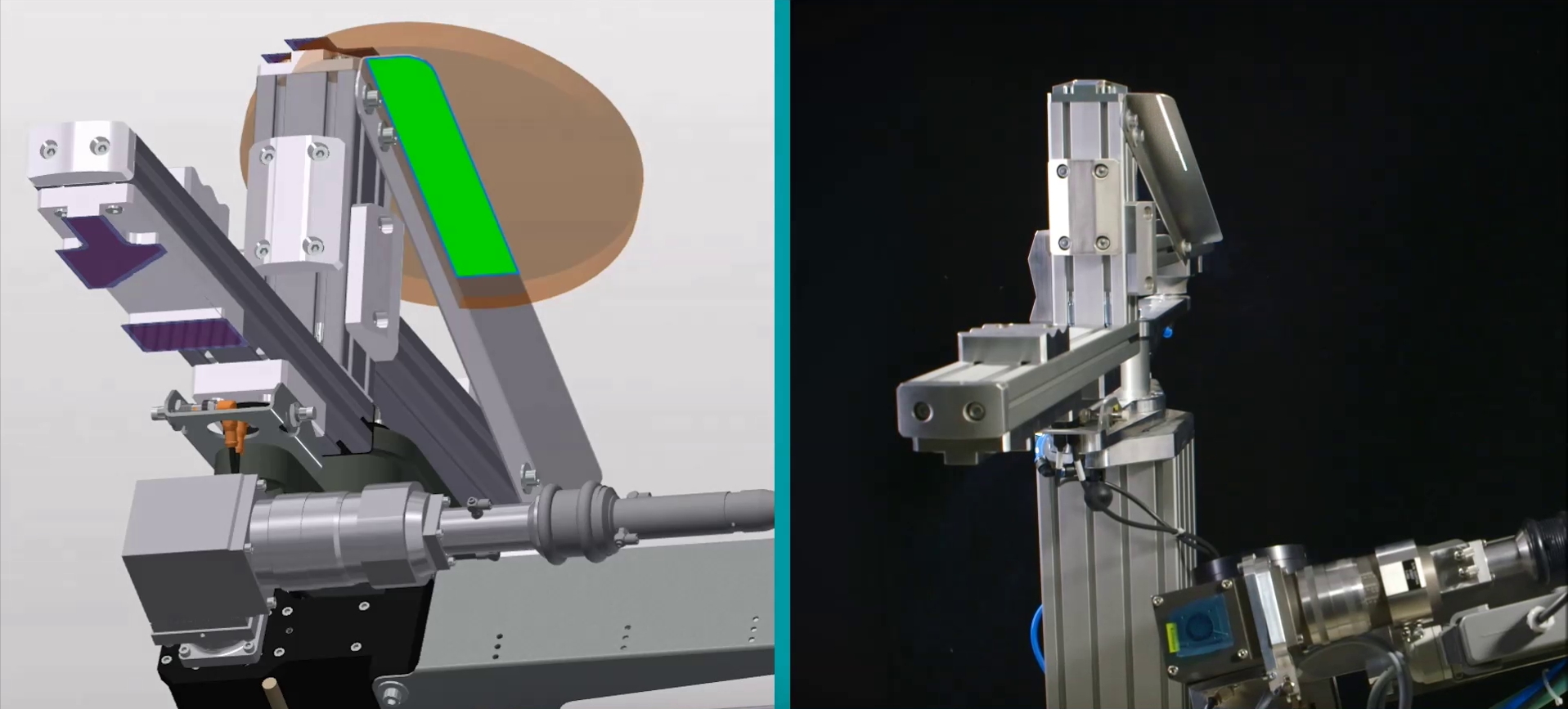

… and our systems are smart

Power is nothing without control: Our smart scanning solutions allow to set and store the intensity, repetition rate and overlap of the laser spots within seconds. Each part or article can hence be processed with a different recipe - without retooling, without downtime. Our powerful SCANYWHERE cleaning engine enables to program complex processing contours on 3D parts with only a few mouseclicks in the CAD drawing of your part. And optional machine vision and process controls allow to monitor cleaning results and laser performance to make sure every part meets the specifications every time.

Get your tailored surface from 4JET

- the broadest portfolio of lasercleaning and surface processing solutions on the market: from low-power to high-power, from manual to fully automated, from OEM engine to turnkey solution – „as a service“ or „as a tool“

- two decades of experience

- our world-class metrology lab equipped with SEM, laser scanning microscopy and peel-testing capability

- regional dedicated support 24h / 7 days a week

Contact

We look forward to your questions – our experts are at your disposal.