4JET's TOPAZ LS/GS

PRODUCTIVITY & VERSATILITY COMBINED

Versatility for Glass or Layer Side Laser Patterning

4JET’s TOPAZ LS/GS is the most versatile solution for laser patterning applications where handling of flat glass sheets is not that critical. These systems are made for a reliable 24/7 production. High resolution and high accuracy are further attributes that make these systems the ideal choice, especially if glass side (GS) laser patterning is required for higher throughput and best product quality, especially in architectural, automotive or technical glass applications. However, by simply flipping the laser patterning head granite beam and axis upside down, the system is transformed into a layer side (LS) patterning TOPAZ.

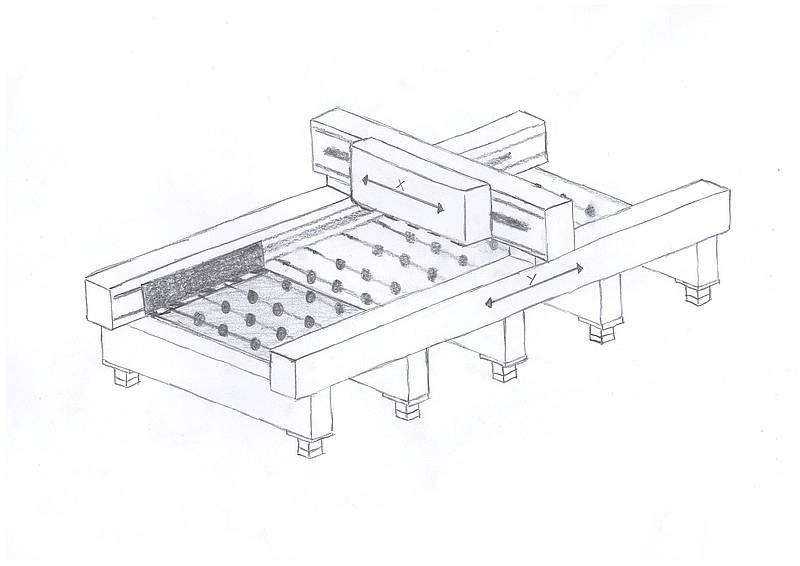

Accuracy and Dynamics

The TOPAZ LS/GS series is based on a granite gantry with one or two separate linear y-axis, gripping the substrate on one or respectively two sides and moving it back and forth at high speed in the system. A stationary granite bridge carries the linear x-axis and can be mounted either above or below the substrate, hence enabling layer side (LS) or glass side (GS) patterning. The system configuration allows the movement of the substrate back and forth for patterning, while the laser patterning head(s) rests, or the moving of the laser patterning head(s) while the glass rests. The latter promises the highest accuracy because any glass sheet vibration is avoided.

Furthermore, the movement of a compact patterning head provides higher dynamics. The beam path is relatively short for a stable and thus accurate beam position across the substrate. The glass substrate is supported against bending during its movement to provide stability and in particular a stable focus plane for the laser. The system’s robustness, vibration dampening capability and stability, especially in terms of long-term accuracy is achieved by the granite and its low coefficient of temperature expansion (CTE) - being four times smaller than the one of steel. This enables and guarantees a sustainable production of high-precision and high-quality products.

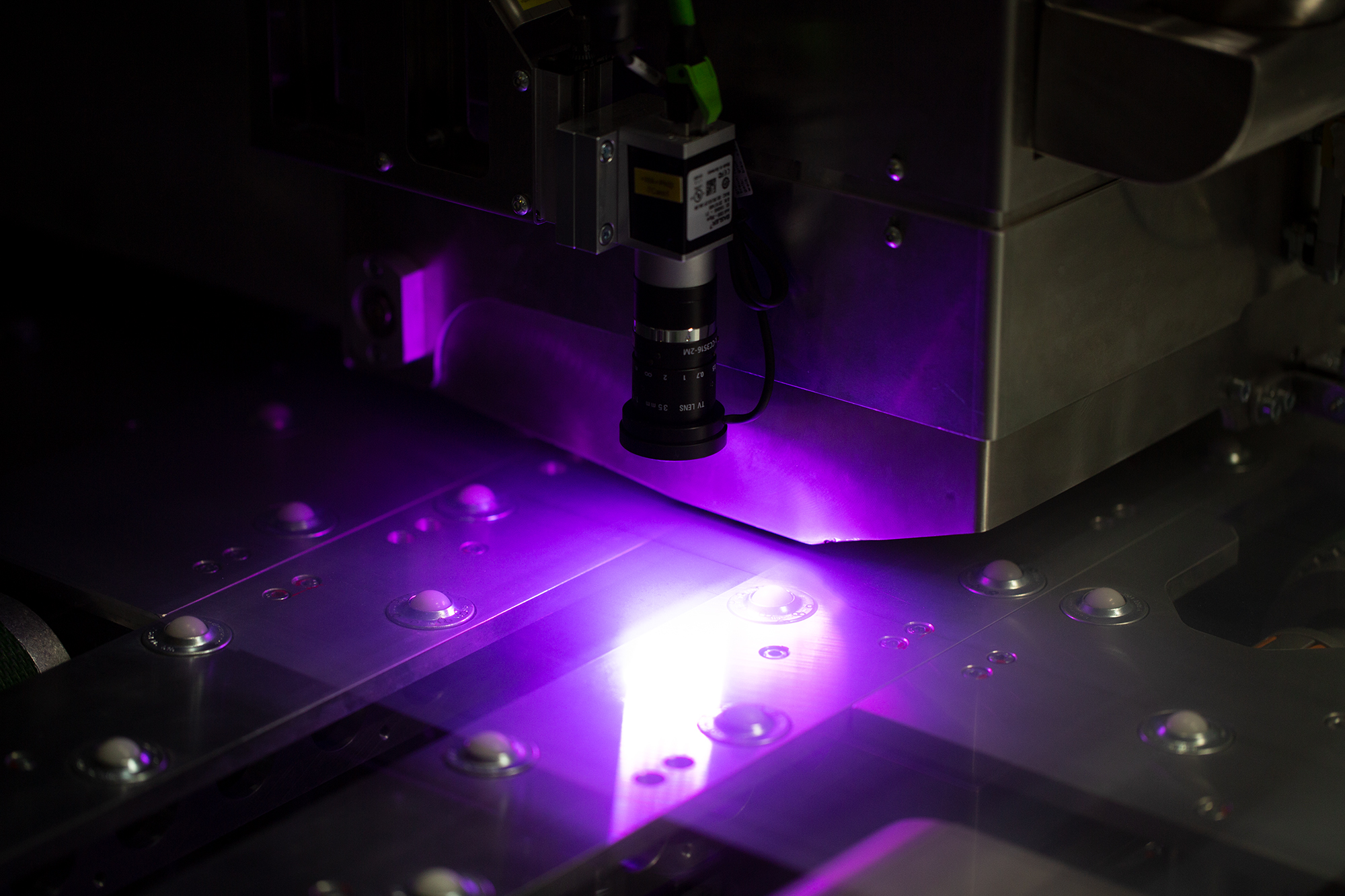

Scanning-on-the-fly: The High-speed Core of the TOPAZ LS/GS

Depending on the required pattern resolution and the cycle time requirements the patterning axis can be equipped with multiple scanners, operating in the scanning-on-the-fly mode which increases the machine’s throughput and reduces production costs.

The laser wavelength and pulse length and thus the laser source is chosen according to the specific requirements of the application for best product quality and taking into account economical aspects. Additional optional features like e.g. the TOPAZ DYNAMIC FOCUS provide additional means to achieve an optimal product quality, e.g. in case the incoming glass substrate deviates from a flat shape.

Specification

| Thin-films | transparent conductive oxides (ITO, ZnO, SnO2, FTO), Silver coating systems), Molybdenum, PV-absorber, etc. |

| Laser wavelengths | NIR, VIS, UV |

| Laser pulse lengths | femto-, pico- or nanoseconds |

| Patterning resolution | 15 µm to 100 µm (depending on wavelength and optical configuration) |

| Processing | ablative patterning from the glass or film side |

| Scanning on-the-fly | optional, 2D-scanning head based |

| number of processing heads | multiple (depending on tact time requirements) |

| Working area (x, y) | scalable |

| Substrate dimensions | customer specific within machine working area specification |

| Glass thickness | 1.8 mm up to 6 mm |

| Axis speed | up to 2 m/s |

| Position Accuracy @temperature range 22 ± 2C° | +/- 15 µm, higher accuracy upon request +/- 20 µm relative to fiducial system (TOPAZ FIDUCIAL required) |

| Particle extraction | high volume flow at medium pressure |

| MES interface | optional |

| Footprint | depending on working area |

| Weight | depending on machine size |

| Loading and unloading | manual or automatic |

| Additional features | TOPAZ DYNAMIC FOCUS TOPAZ FIDUCIAL MOBILE HMI |

Contact

We look forward to your questions – our experts are at your disposal.