Optimization of solar cells

In the production of thin-film cells, precise electrical isolation through high-precision and selective laser structuring is the key to efficient PV modules. We develop and supply state-of-the-art laser technologies that are capable of accomplishing this task with maximum efficiency.

Short cycle times and unmatched flexibility

Our many years of experience and our advanced systems enable us to process thin-film modules from both the glass and the layer side in a highly productive manner. Depending on the application, our systems are equipped with highly accurate and fast scanning processes, or have a variety of flying optics. This not only achieves very short cycle times, but also unprecedented flexibility in the production of high-efficiency PV modules.

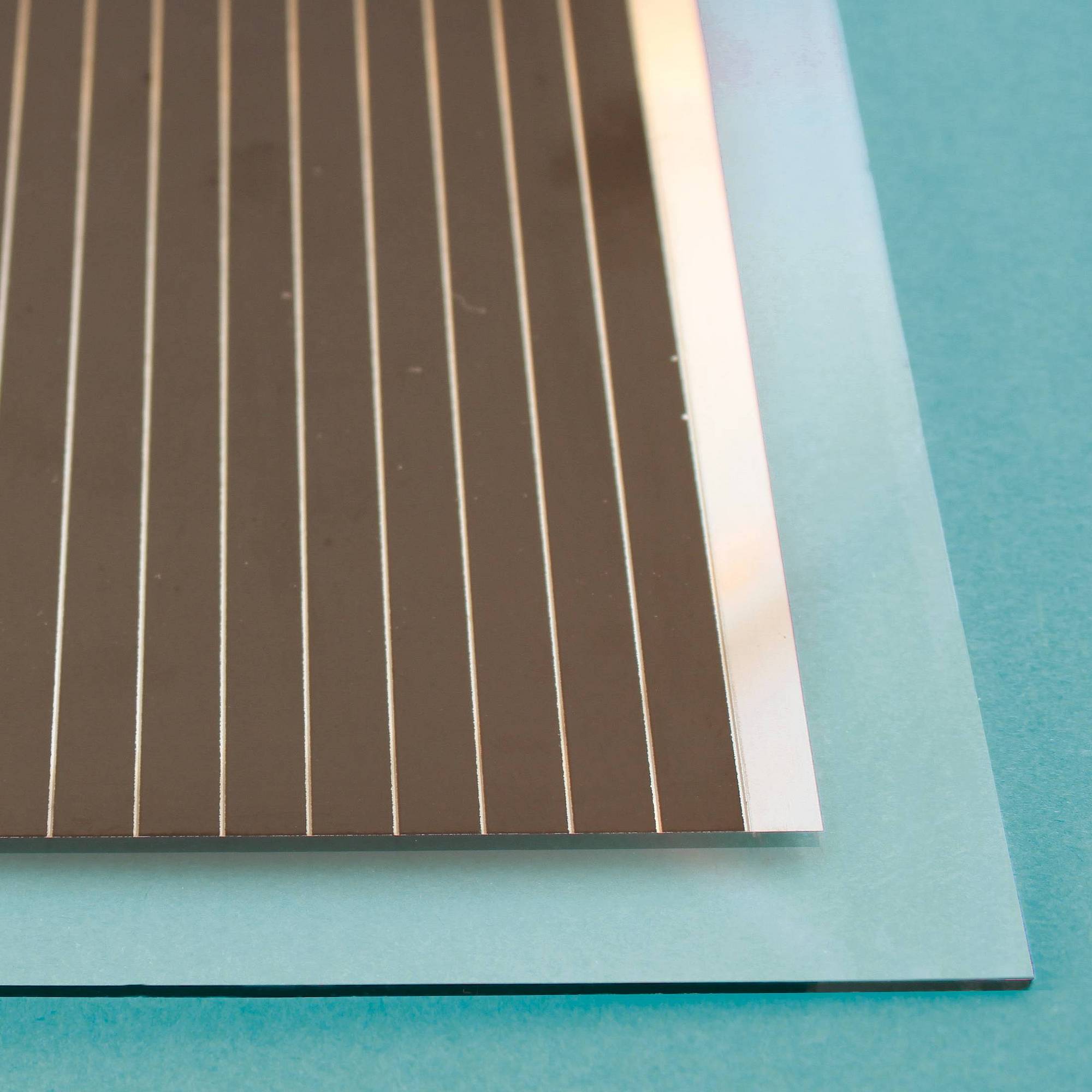

Laser Scribing

Laser scribing is an enabling technology for manufacturing thin-film solar modules. It separates the thin-film module in thin stripes of cells to achieve a high voltage at a low current. Through alternating coating and scribing steps the so called monolithic interconnection is achieved. Laser scribing usually comprises the front electrode, absorber and back electrode structuring by means of narrow isolation groves with a width well below 50 µm.

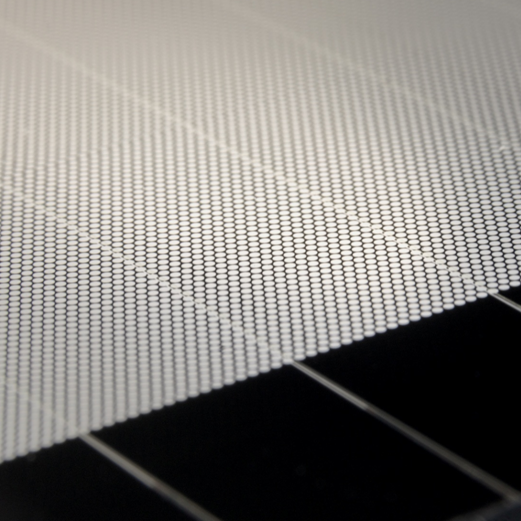

Laser Structuring

One way to realize building integrated PV (BIPV) is to use solar modules as windows, either by making the absorber semi-transparent or by using transparent absorbers per se. Our high-precision TOPAZ is able to create patterns with a homogeneous distribution in the absorber to achieve a perfect appearance.

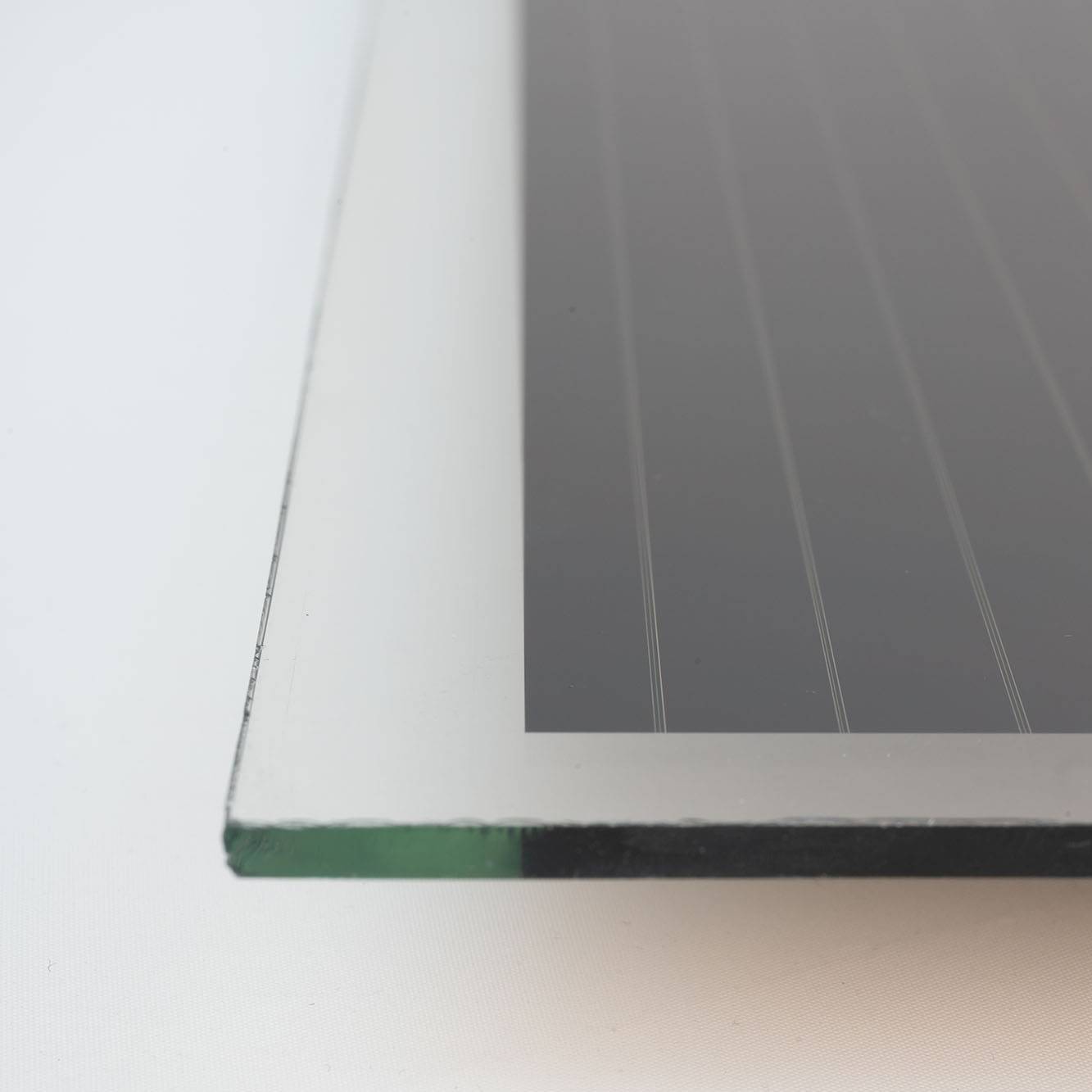

Laser Edge Deletion

Laser edge deletion is a touchless process with no damage to the substrate. It also does not produce microcracks. It is an environmentally friendly and dry process that works without blasting media or chemicals. No post-cleaning is necessary. Further advantages over mechanical blasting processes or the use of grinding wheels are the reproducibility of the results and the increased module efficiency due to the reduction of the dead zone.

CIGS Backend Processing

CIGS solar production is one of the promising thin film technologies. Based on our many years of experience in manufacturing production equipment, we have developed the MPCT, which combines 3 processes in one system and enables high throughput on a small footprint, synonymous with high cost efficiency!