About us

We use laser technology to enable tomorrow’s production. Combining innovation, excellence, and passion, our solutions serve customers in demanding industries around the world.

Get to know us.

How Our Solutions Create Impact

Sustainability

Laser technology enables resource efficiency on many levels. Just a few examples:

Management and Legal Representatives

The 4JET group combines several closely connected legal entities

under the roof of one holding company.

Management

Head of Business Line Glass & Semicon

Board

Innovation and Growth Highlights

Facts & Figures

4JET Sales+Service GmbH was founded by CEO Jörg Jetter in Hückelhoven.

employees in Germany, China, and the United States work across development, sales, and service.

4JET solutions are used worldwide in demanding industries.

of our machines are exported to customers around the world

of our revenue goes into research and development for our laser systems.

registered IP families demonstrate that we are not imitators, but pioneers of new processes.

Mission & Values

4 Questions for Jörg Jetter, Founder & CEO of 4JET

Mr. Jetter, what makes your laser process solutions stand out?

Our laser process solutions provide quality surfaces by reliable adhesion-, flow-, molding- or electrical properties, as well as high contrast markings or precise and crack-free separation edges in glass.

Many companies are looking for ways to produce more sustainably. How do your technologies contribute to this goal?

We enable sustainable, environmentally friendly production by dry, chemical-free laser processing with virtually no residual materials, and low resource consumption and large greenhouse gas savings compared to conventional processes.

In addition to sustainability, economic efficiency is crucial. How do you support your customers in this regard?

We help customers to be economically successful by offering photonic tools with high repeatability and flexibility, low running cost and a high degree of automation and productivity.

Which values guide you as an entrepreneur and employer?

We want to be fair and reliable business partners and a good employer and corporate citizen that takes responsibility by living up to our commitments, educating the young, prioritizing people’s health over profits and strictly assuring safe and sound business operations. If you want to help us to identify and fix wrong behavior please contact us: Whistleblowing@4jet.de

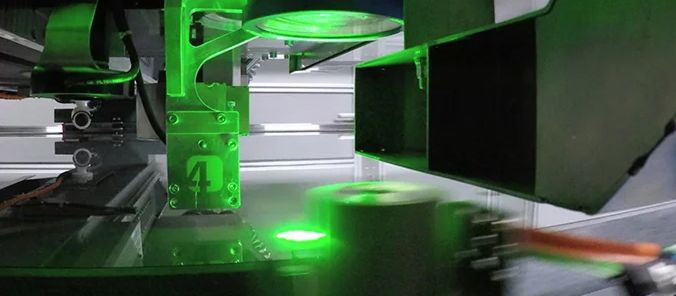

World Class Infrastructure for R&D, Operations and Manufacturing

Relentless innovation is our DNA. Dedication to Excellence whats sets us apart. Our infrastructure and equipment is state of art.

R&D Labs (Alsdorf & Krailling)

With over 2,000m² of lab space featuring dozens of laser sources and more than 10 full scale test machines we are well prepared to work with customers at any stage - all the way “from lab to fab”.

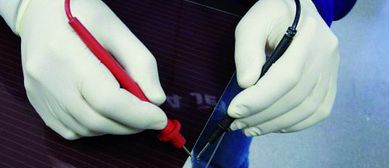

Metrology

Our passion for precision is supported by top-notch metrology, including SEM and laser scanning microscopes, bending test, large area CMM and more.

Manufacturing (Alsdorf & Krailling)

With two production sites in Germany totaling over 10,000m2 of assembly and storage we are well prepared for serial production and order peaks. Our Alsdorf campus features key infrastructure including an automated parts warehouse.