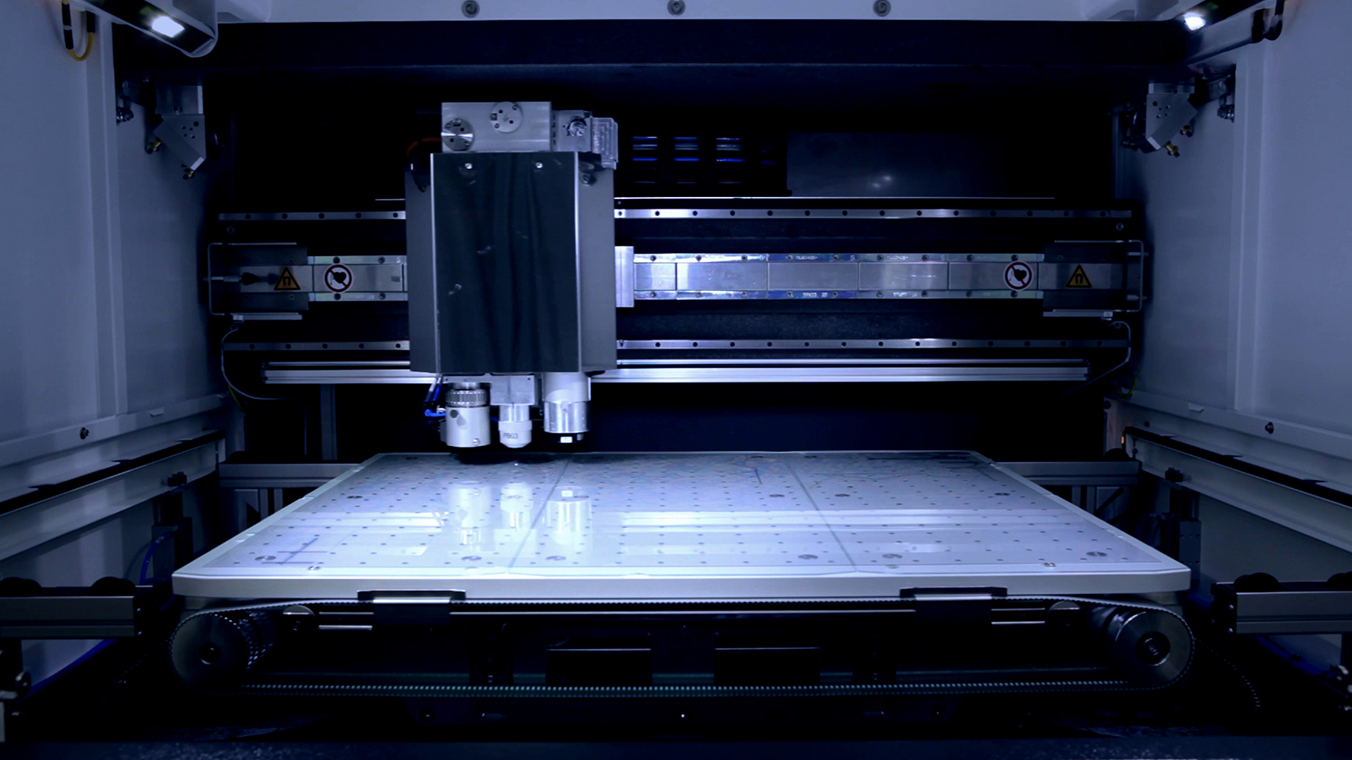

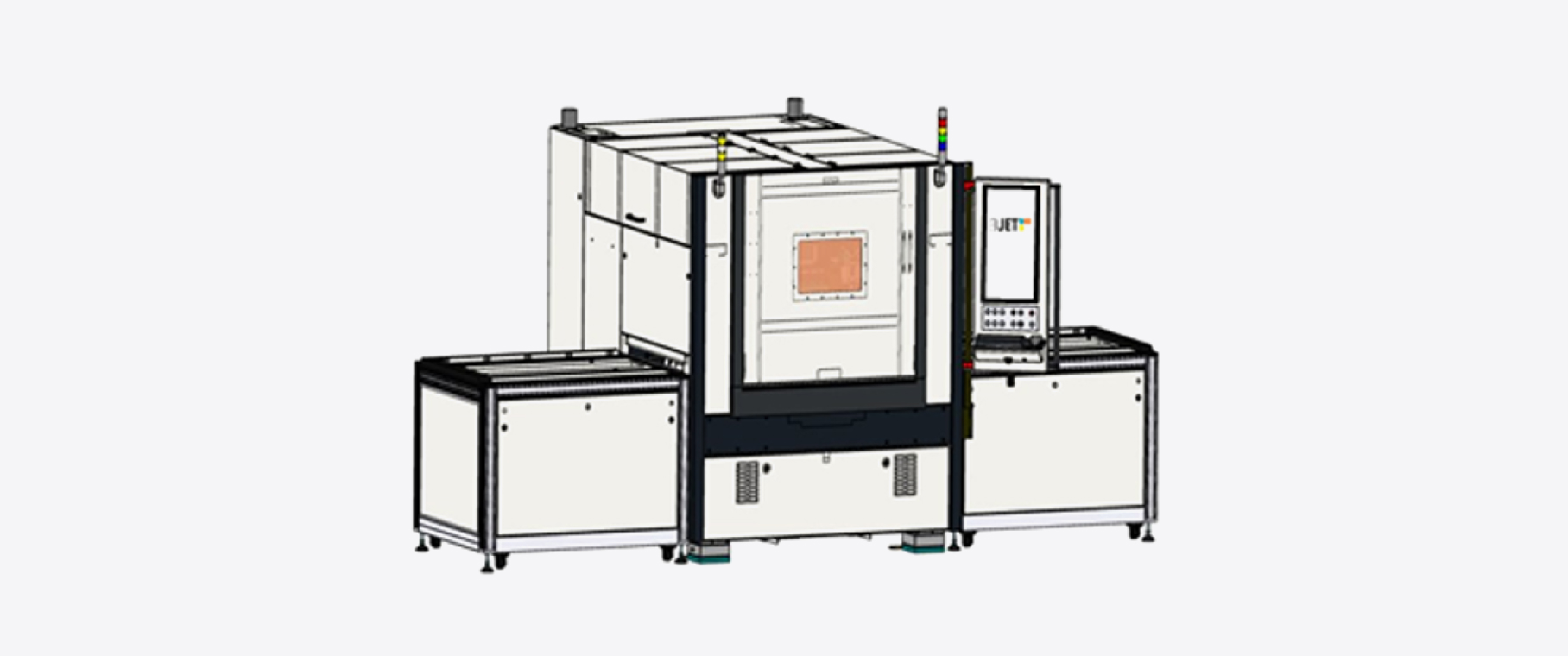

PEARL 900S – High-Precision Glass Processing

The PEARL 900S is a powerful laser system for the precise processing of glass and other transparent, brittle materials.

Designed for continuous 24/7 industrial operation, it also offers the flexibility required for research and development. The platform is built on a massive granite gantry with linear motor axes, combining top-tier processing quality with process versatility and automation options.

By integrating state-of-the-art laser processes such as nanoPerforation, thermal separation, laser drilling, and marking, the PEARL 900S is the ideal solution for demanding applications in the semiconductor, optics, automotive, aerospace, photovoltaic, and glass industries, as well as in consumer electronics.

Highlights der PEARL 900S Plattform

Applications of the PEARL 900S

The PEARL 900S is suitable for special applications in photovoltaics where large-format glass substrates (< 900 mm) must be processed with high precision – for example, for edge stripping, layer structuring, or drilling in BIPV modules or thin-film systems for R&D. The contactless laser process delivers maximum precision with minimal thermal and mechanical impact – ideal for sensitive multilayer functional coatings.

Processing large-format glass substrates for the electronics and semiconductor industry. Typical applications include cover glasses for tablets and smart displays, camera modules, sensor covers, and substrates for advanced packaging, MEMS, and glass core. Capable of producing through-holes, vias, complex geometries, and layer removal – contactless and with the highest edge quality.

Optimized for large glass and glass-ceramic components in automotive and aerospace applications. Examples include curved displays, touch interfaces, head-up displays, sensor covers, automotive mirrors, and optical systems. nanoPerforation and thermal separation enable precise freeform cuts, inner contours, and drilling – contactless, low-stress, and with the highest edge quality. Even 3D-shaped glass can be processed with high accuracy.

Perfect for large flat glass processing in technical and architectural applications. Typical uses include smart windows, functional façade elements, optical partitions, and technical glass covers. nanoPerforation and thermal separation allow for precise freeform cuts, internal cutouts, and structured edges – contactless, clean, and with minimal material loss. Ideal for formats between 400 and 900 mm where top quality and flexibility are essential.

Excels in processing large-format optical substrates made of glass, quartz, or glass ceramics. Common applications include optical windows, filter carriers, lens blanks, beam splitters, and other precision components. nanoPerforation, thermal separation, and layer removal enable the creation of complex geometries, precise drillings, and structured edges – contactless, low-stress, and with the highest optical quality.

PEARL 900S – Variants & Process Options

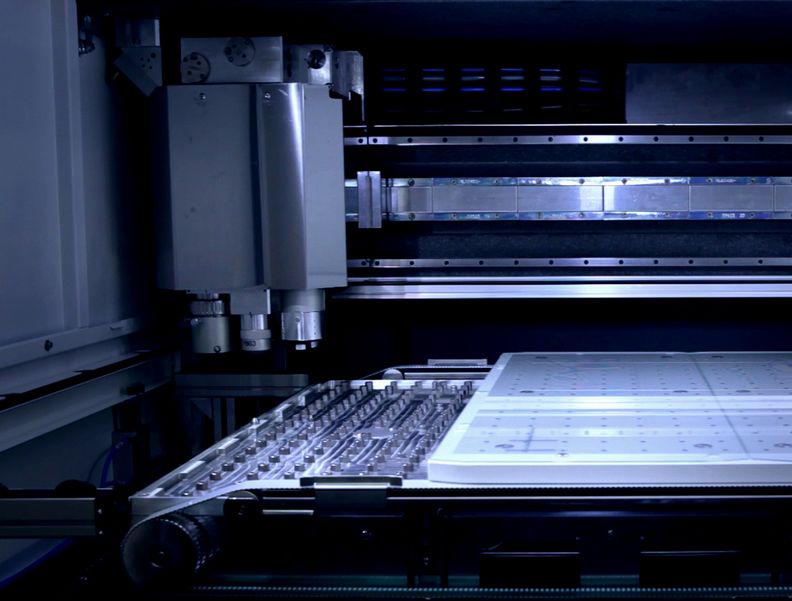

Configurable with various process heads depending on the application:

nanoPerforation process head

Patented glass cutting process with minimal substrate damage and high edge strength

Enhanced nanoPerforation

Higher throughput and capability for complex geometries

Separation process head

Thermal separation without mechanical stress – ideal for sensitive substrates

Enhanced Separation

More powerful version for thicker substrates or more complex separation geometries with improved edge quality and minimized impact on coatings

Drilling head – scanner-based

Precise laser drilling for vias, through-holes, blind holes, and more

Marking Process Head

Permanent marking of 2D codes, serial numbers, or process data

Technical Details:

| Category | Feature | Specification |

|---|---|---|

| System size & weight | Dimensions (W×D×H) | 1750 mm × 2450 mm × 2720 mm |

| With supply rack | 3150 mm × 2450 mm × 2720 mm | |

| Weight | ~4,500 kg | |

| Axes & movement | Machining area | 730 mm × 920 mm |

| Feed speed | 1000 mm/s | |

| Acceleration | 10 m/s | |

| Dimensional accuracy | < 2.5 µm + 7.5 × 10⁻⁵ × L | |

| Repeatability | ≤ 2 µm | |

| Software & operation | HMI | Touchscreen-based user interface |

| CAD import | DXF, simple job configuration | |

| Vision system | cVision with fiducial and edge detection | |

| MES connection | SECS/GEM (optional) |

Available Options:

- Enhanced nanoPerforation

- Enhanced Separation

- Height sensor

- Beam profiler

- Ionizer

- Humidity booster

- Earthquake Protection

- Transformer

- Chiller (PCW)

- Remote Access (GenuBox)

- 2D code marking

- 2D code reading