Display

High-Precision Laser Processing for Advanced Display Manufacturing

From smartphones to wearables and automotive displays, we provide laser solutions for cutting, drilling, and structuring of technical glass used in high-performance flat, curved, and flexible display technologies.

The Role of Laser Processing in Display Innovation

The evolution of display technology – from rigid LCDs to flexible OLEDs – demands ultra-clean, high-precision glass processing. Display manufacturers rely on contact-free, scalable solutions to cut, structure, and mark delicate glass substrates without compromising yield or visual performance.

The display industry continues to evolve toward larger formats, thinner profiles, curved geometries, and higher integration density. Whether in OLED, mini-LED, or microLED applications, the need for crack-free cutting, micro-feature integration, and precision glass shaping is growing rapidly.

Our advanced laser systems enable stress-free processing of ultra-thin glass, coating ablation, and feature machining – ideal for materials such as aluminosilicate, borosilicate, and composite display stacks. Our solutions meet the stringent edge quality, dimensional tolerance, and cleanliness requirements of modern display fabs.

Key Technical Features for Display Glass Processing:

Precision Cutting of Display Glass

Applications:

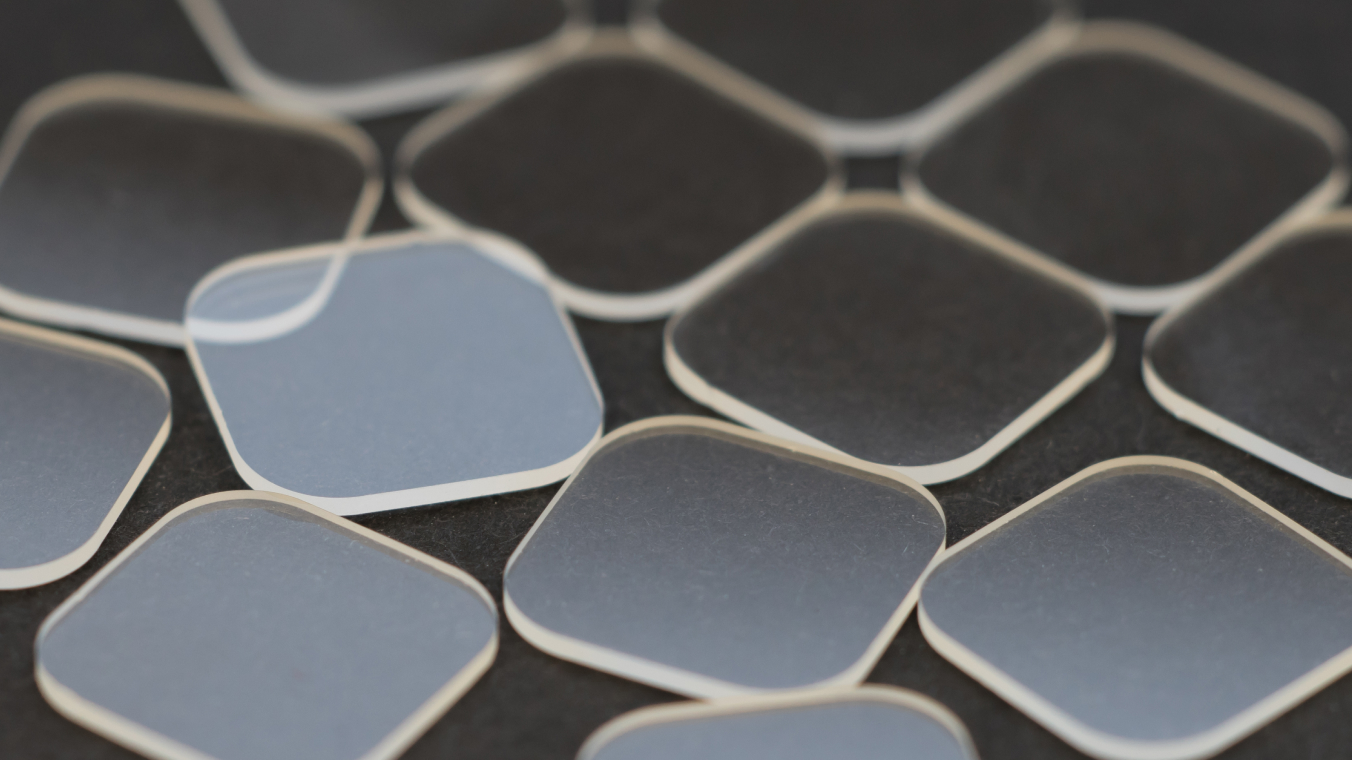

- Separation of mother glass into display panels

- Contour cutting of rigid and flexible TFT, OLED /miniLED, and LCD substrates

- Straight and complex shapes for rigid, curved, or flexible displays

- Compatible with ultra-thin and chemically strengthened glass

- Cutting of cover glass and curved display components

4JET Technology Fit:

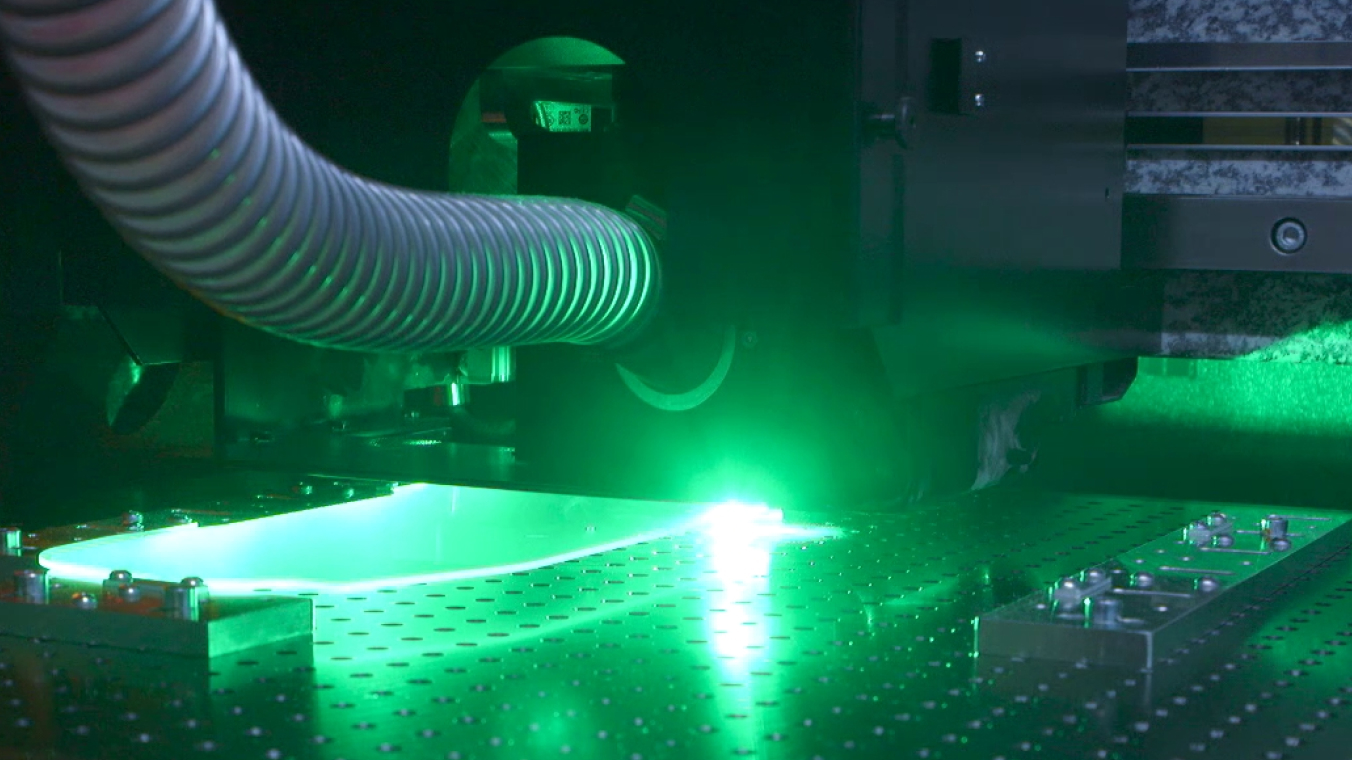

- Bessel beam laser cutting for crack-free, low-damage edges with excellent bending strength

4JET Solution:

- Clean, chip-free cutting without mechanical stress – ideal for Gen 5+ lines and thin glass < 0.5 mm

4JET Platforms:

Edge Structuring for Foldable and Curved Displays

Applications:

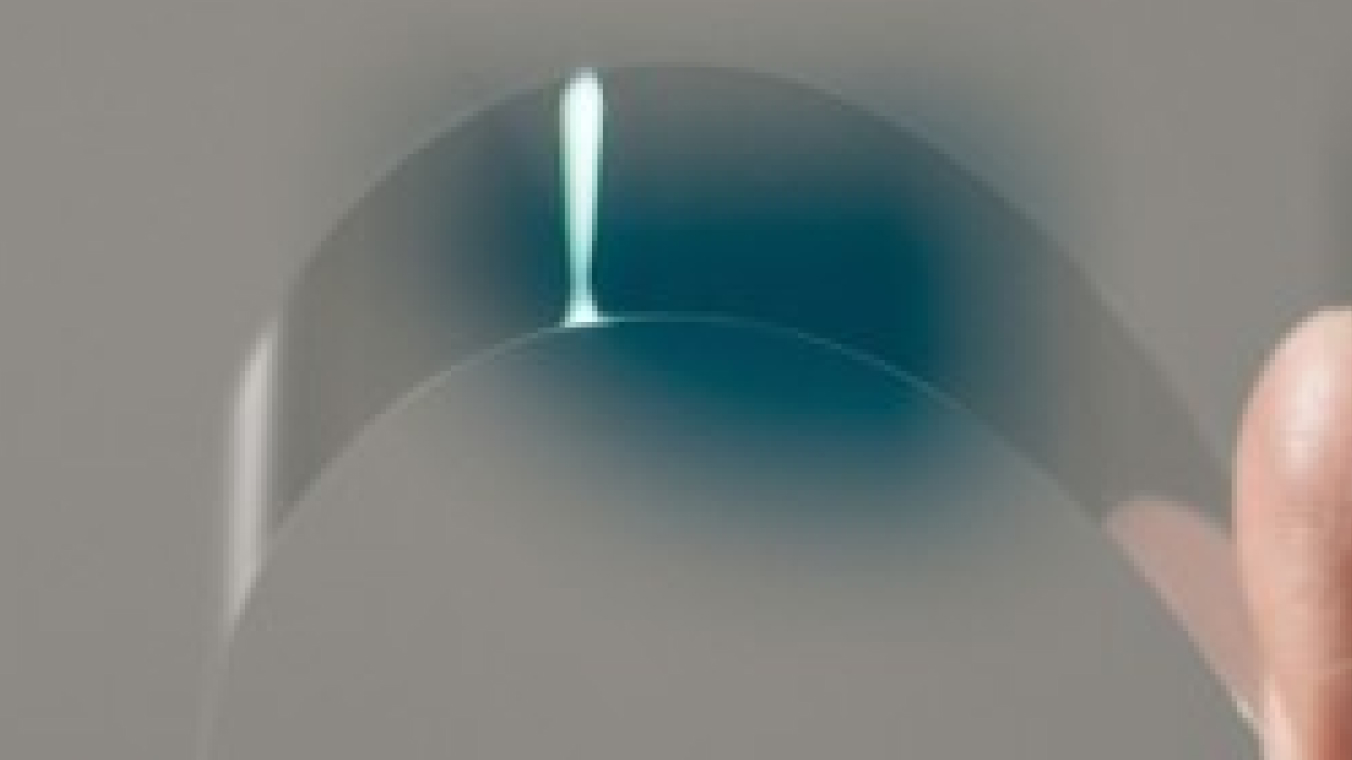

- Micro-chamfering and shaping of foldable screen edges

- Reinforcement of thin glass for flexible display integration

4JET Technology Fit:

- Laser edge shaping with micron-level control and no mechanical stress

4JET Solution:

- Contactless edge finishing for curved and wraparound designs

4JET Platforms:

Micromachining of Display Glass

Applications:

- Speaker ports, sensor holes, and camera openings

- Feature creation in wearable display covers and touch stacks

4JET Technology Fit:

- Ultrashort pulse (USP) laser micromachining with high aspect ratio control

4JET Solution:

- Crack-free, precision features with no debris – suitable for downstream lamination and sealing

4JET Platforms:

Selective Coating Removal and Patterning

Applications:

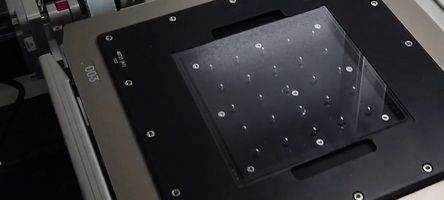

- TO and metal layer ablation for sensor or electrode patterning

- Definition of bonding zones, electrical contacts, or insulation lines

4JET Technology Fit:

- High-resolution, high-speed laser ablation with minimal thermal load and substrate protection

4JET Solution:

- Vision-guided patterning of multi-layer stacks without substrate damage

Thin Glass Processing for Flexible Displays

Applications:

- Cutting and shaping of glass <0.5 mm for OLED encapsulation or carriers

- Rollable, foldable, or curved display stack processing

- Processing of flexible OLED encapsulation layers or glass carriers

4JET Technology Fit:

- Low-stress laser separation with high edge quality

4JET Solution:

- Ideal for ultra-thin glass in wearables, foldables, and automotive HUDs

4JET Platforms:

Prototyping & Custom Structuring

Applications:

- R&D display layouts and pilot production

- Development of new formats and design variants

4JET Technology Fit:

- Software-controlled direct-write laser processing

4JET Solution:

- Fast reconfiguration and high-precision results for custom needs

Why 4JET?

Trusted partner in mobile, automotive, and large-format display manufacturing

Scalable laser platforms from pilot lines to Gen 6+ fabs

Zero-contact, high-yield processes for next-gen display materials

IP-protected solutions trusted in consumer electronics and precision optics industries

Let’s Shape the Future of Display

Speak with our experts about laser solutions for cutting, structuring, or feature integration in advanced display applications.

Enabling Capabilities Across All Display Applications

Whether it’s high-volume cover glass production, advanced OLED stacks, or innovative display integration – we deliver precision, reliability, and scalability across the entire display value chain. Our enabling capabilities complement laser systems with automation, software, and production support.

Core4 Software Platform Global Services & Support Automation Integration

Core4 Software Platform

All 4JET display solutions are powered by Core4 – our industrial-grade, modular software ecosystem.

- Intuitive UI/UX for complex, multi-step display processes

- AI-based vision tools for glass alignment, coating recognition, and defect detection

- Seamless recipe control, data logging, and PLC sequencing for display production lines

- Supported by a large in-house dev team ensuring fast updates and redundancy

Automation Integration

Automation tailored to the throughput and cleanliness needs of display production:

- Robotic and tray-based handling for fragile or ultra-thin substrates

- Inline integration with upstream/downstream process equipment

- MES connectivity and barcode integration for Industry 4.0 factories

Let’s Shape the Future of Display

Speak with our experts about laser solutions for cutting, structuring, or feature integration in advanced display applications.