Medical

High-Precision Laser Processing for Medical-Grade Glass Components

Our laser technologies enable ultra-clean, high-precision machining of glass and glass-ceramic components used in diagnostics, surgical tools, and implantable devices – ensuring full compliance with biocompatibility, traceability, and sterilization standards.

Precision Glass Processing for Medical Technology

In medical technology, precision, cleanliness, and regulatory compliance are non-negotiable. From point-of-care diagnostics and surgical optics to implantable devices and sterilizable systems, medical glass components must be processed without introducing microcracks, thermal stress, or contamination.

Our laser-based micromachining platforms deliver non-contact, tool-free solutions for cutting, drilling, texturing, and selective coating removal. Our cleanroom-compatible systems ensure process stability, traceability, and reproducibility – supporting both R&D and high-volume production of critical medical devices.

Key Technical Features for Medical Glass Processing:

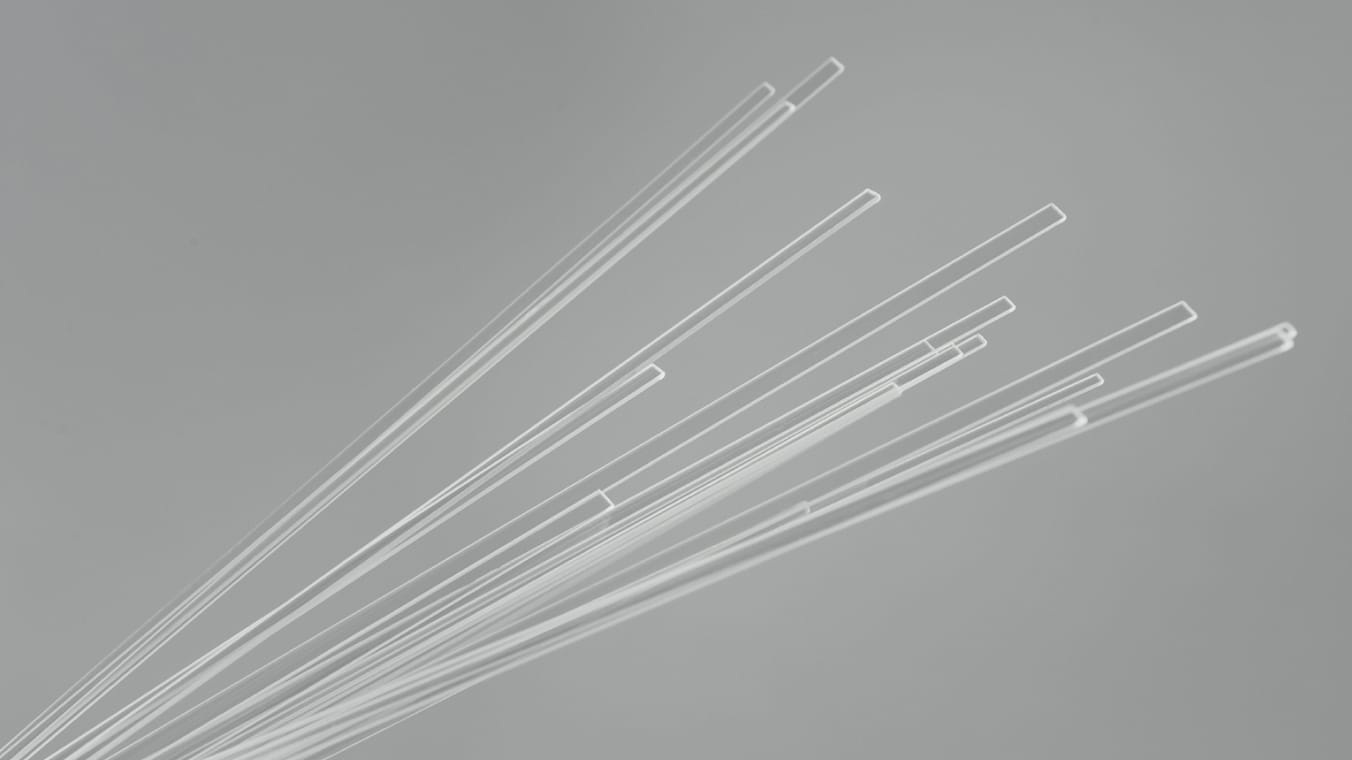

Cutting of Medical-Grade and Bio-Inert Glass

Applications:

- Precision shaping of diagnostic, surgical, or implantable glass components

- Cutting of borosilicate, fused silica, or quartz materials for sterile use

4JET Technology Fit:

- Bessel beam laser cutting for crack-free edges, high optical quality, and superior edge integrity – eliminating the need for post-grinding

4JET Solution:

- Contactless and contamination-free separation – ideal for sealed, implantable, or sterilized devices

4JET Platforms:

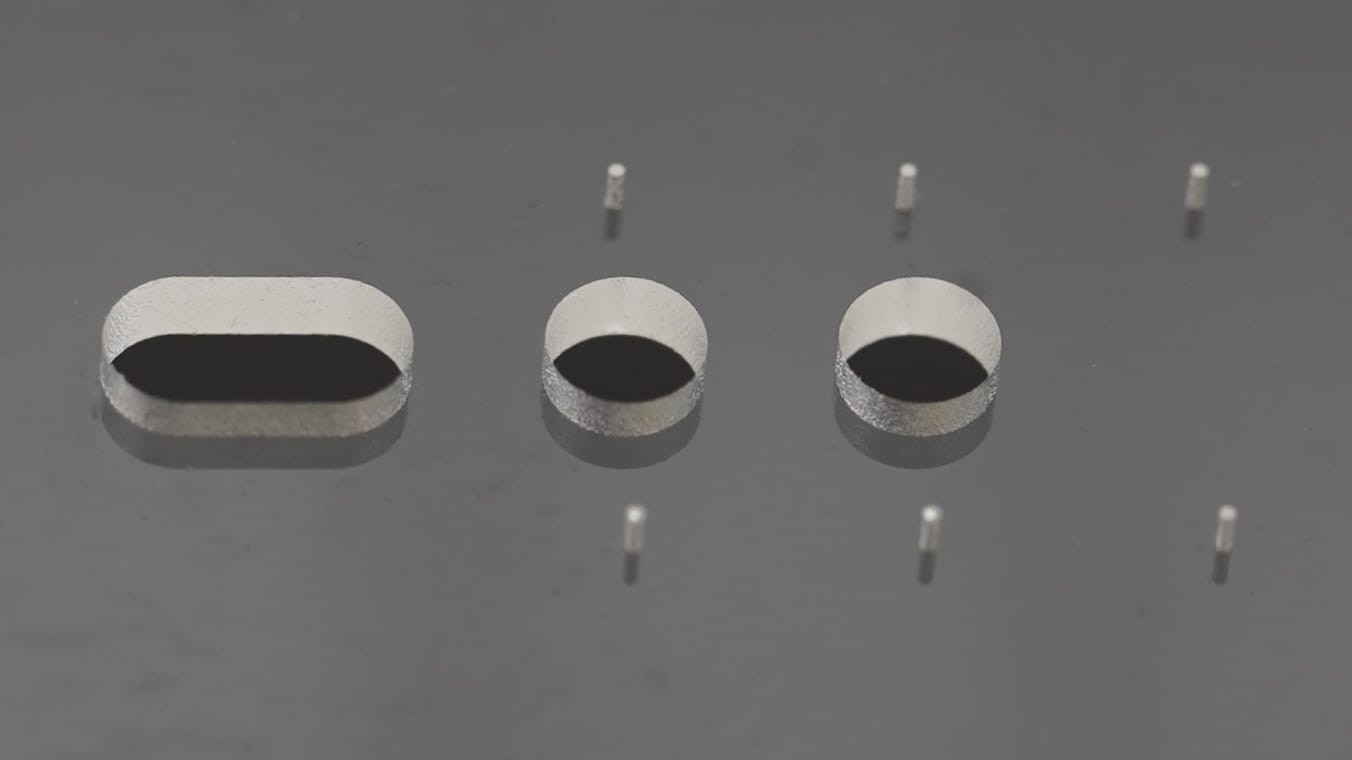

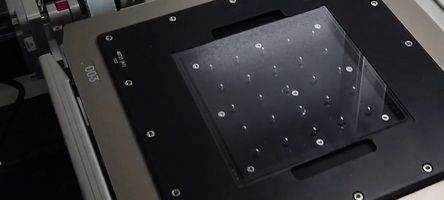

Drilling & Micromachining for Surgical and Diagnostic Devices

Applications:

- Venting holes, fluidic access ports, or fixation features in miniaturized glass parts

- Multi-layer drilling for sensor integration or channel routing in implantable devices

4JET Technology Fit:

- Ultrashort pulse (USP) lasers for high-aspect-ratio features with zero burrs or cracks

4JET Solution:

- Repeatable, debris-free hole formation for fluid-tight and functional medical assemblies

4JET Platforms:

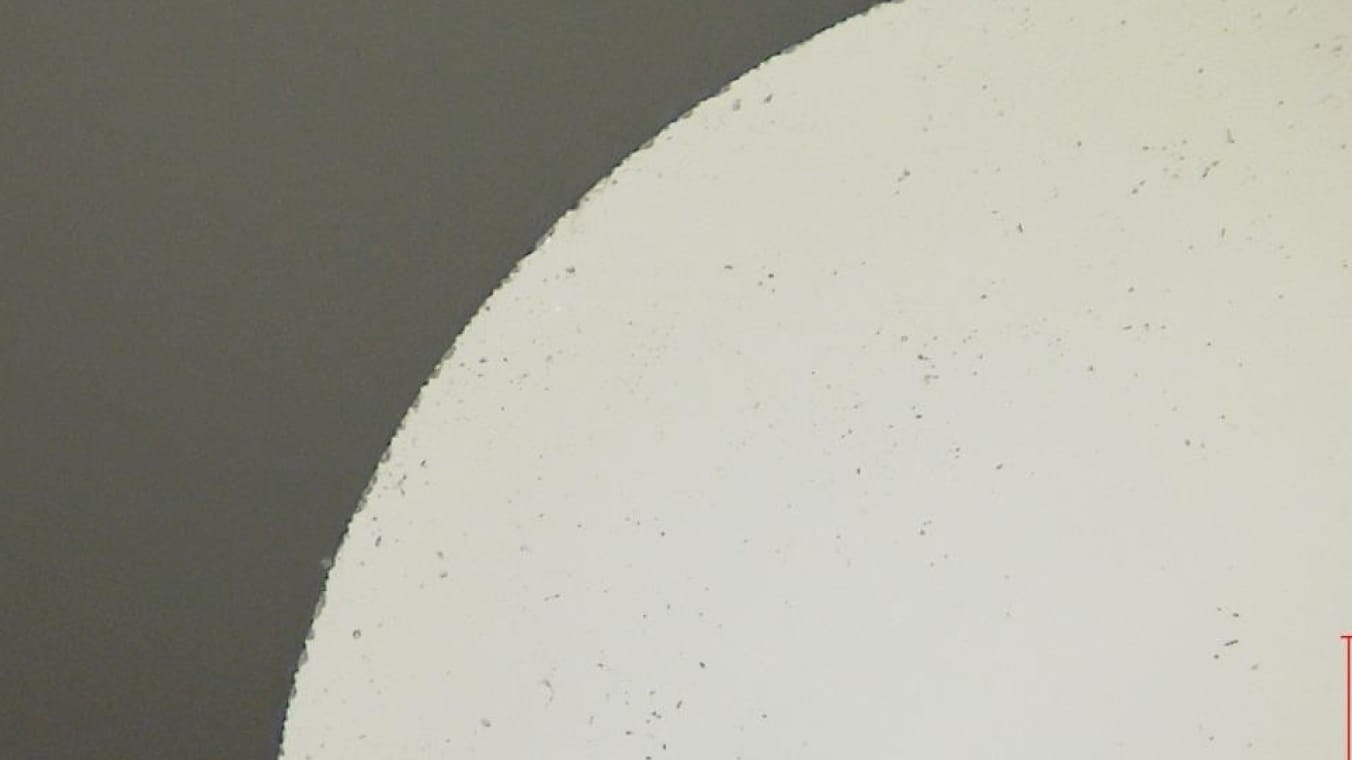

Surface Structuring for Bioactive and Optical Performance

Applications:

- Enhancing bonding, optical behavior, or wettability of glass surfaces

- Creating textures for anti-fog, hydrophilic, or anti-reflective functionality

4JET Technology Fit:

- Sub-micron laser texturing with tunable roughness and optical-grade finish

4JET Solution:

- Contactless, sterile-ready processing for implantables, surgical optics, and diagnostic windows

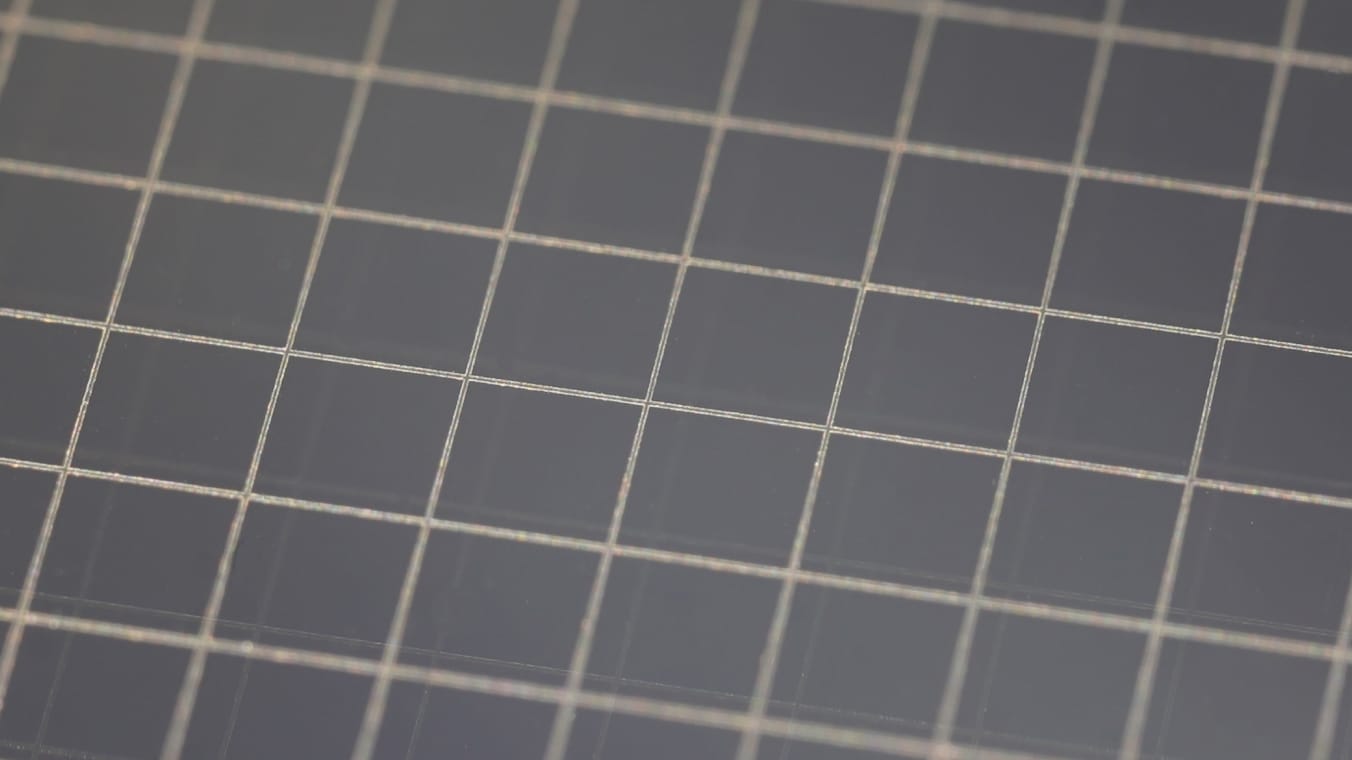

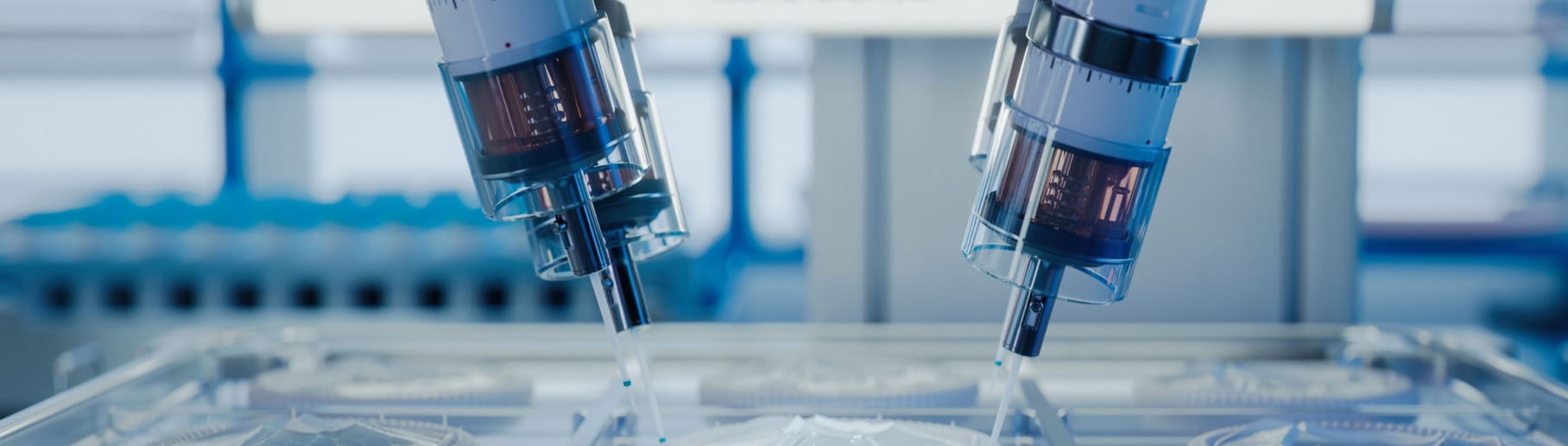

Glass Processing for Diagnostic Consumables

Applications:

- Machining and dicing of glass components in single-use devices (e.g., blood tests, PCR)

- Feature creation in disposable fluid delivery and analysis systems

4JET Technology Fit:

- Compact, high-throughput systems for rapid prototyping and automated production

4JET Solution:

- Compact, modular systems for cleanroom integration and automation readiness

4JET Platforms:

Coating Removal on Functional Glass Components

Applications:

- Selective ablation of coatings for contacts, sensors, or bonding zones

- Used in smart implants, imaging optics, or diagnostic interfaces

4JET Technology Fit:

- Vision-guided, layer-specific laser ablation with micron-scale control

4JET Solution:

- Biocompatible processing with no residual thermal impact – ensuring functionality and safety

Why 4JET?

Cleanroom-ready systems for regulated medical and life sciences manufacturing

Proven processing of borosilicate, fused silica, and medical-grade glass-ceramics

Established solutions for surgical optics, implantables, diagnostics, and life science devices

Particle-free, high-precision machining compatible with sterilization workflows

Cleanroom-integrated platforms trusted for traceability, safety, and performance

Designing Medical Devices with Glass?

Let’s explore how our laser systems can meet your technical, regulatory, and quality requirements.

Enabling Capabilities Across All Medical Applications

Precision, compliance, and reproducibility are fundamental in the medical device sector. Our systems are engineered to support high-value applications such as surgical tools, implants, diagnostic cartridges, and sterile packaging – delivering unmatched laser performance and quality assurance.

Core4 Software Platform Global Services & SupportAutomation Integration

Core4 Software Platform

All 4JET medical solutions are powered by Core4 – our scalable software backbone designed for validated environments and long product lifecycles.

- Modular architecture for laser process, vision, motion, and compliance modules

- Intuitive UI/UX for minimal operator training and fast deployment

- Audit trail logging and process parameter locking for GMP and FDA compliance

- AI-driven inspection and process control tools for critical feature verification

Designing Medical Devices with Glass?

Let’s explore how our laser systems can meet your technical, regulatory, and quality requirements.