Precise, Clean, and Contact-Free Surface Treatment with Laser Technology

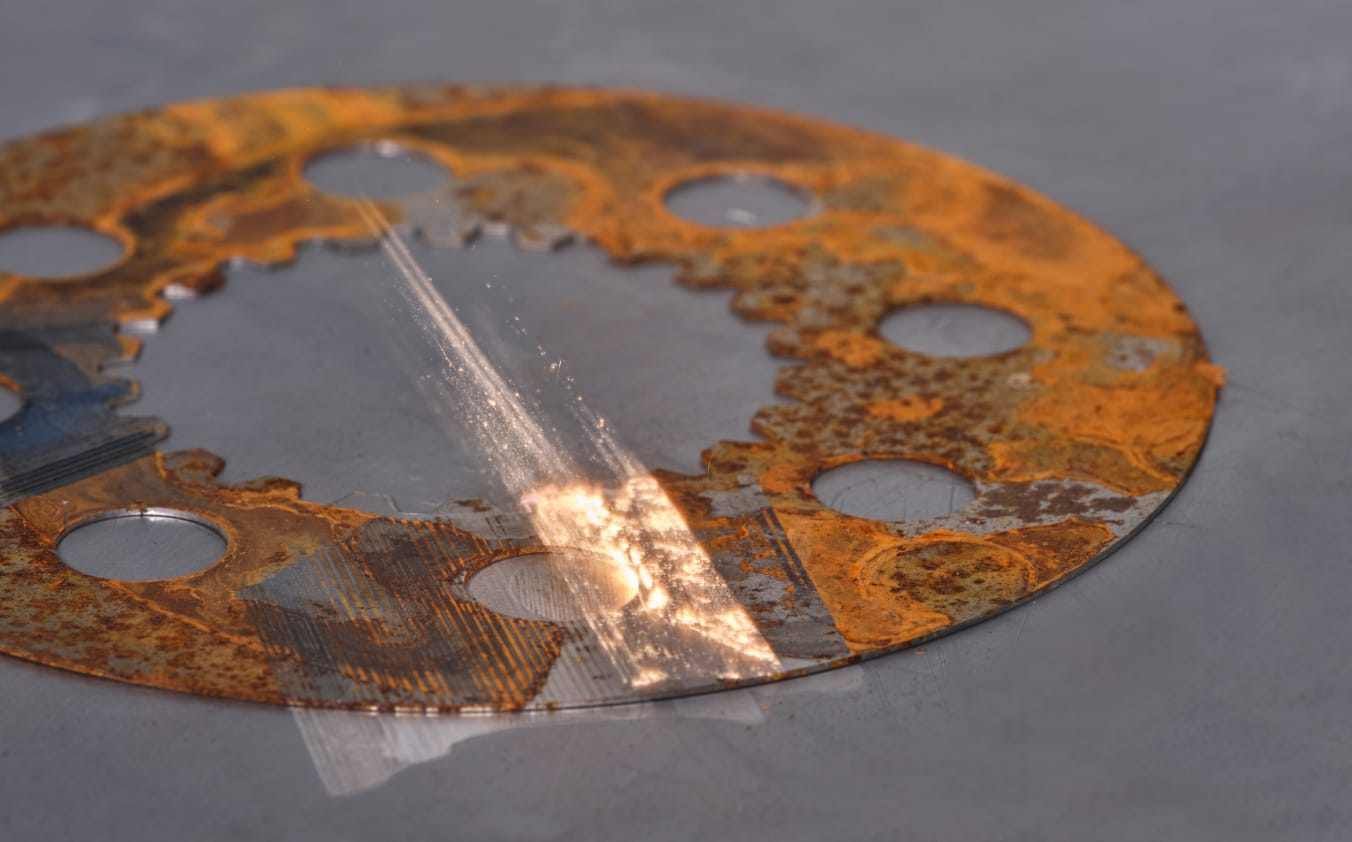

Laser cleaning is a contactless and highly efficient technology that removes rust, paint, coatings, oxides, or contaminants without chemicals, abrasives, or manual labor. It is widely used across various industries due to its precision, speed, and minimal environmental impact.

Cleaning Surfaces with Laser –

Your Benefits in the Spotlight

From Automotive to Aviation: Typical Applications Across Industries

Mobile Laser Cleaning Systems

Ideal for flexible, on-site use where mobility and adaptability are crucial:

Machine and Equipment Maintenance

- Rust removal

- Paint stripping

- Weld seam preparation

- Removal of oil and lubricant residues

Building Restoration & Renovation

- Soot removal after fire damage

- Paint removal on wood or sensitive surfaces

- Removal of heat discoloration (tempering colors) or graffiti

Construction & Infrastructure

- Corrosion removal on steel structures, bridges, pipelines

- Surface preparation on site

Cultural Heritage & Conservation

- Gentle cleaning of monuments, sculptures, and historical buildings

Shipbuilding & Rail

- Surface maintenance, rust and coating removal from large steel areas

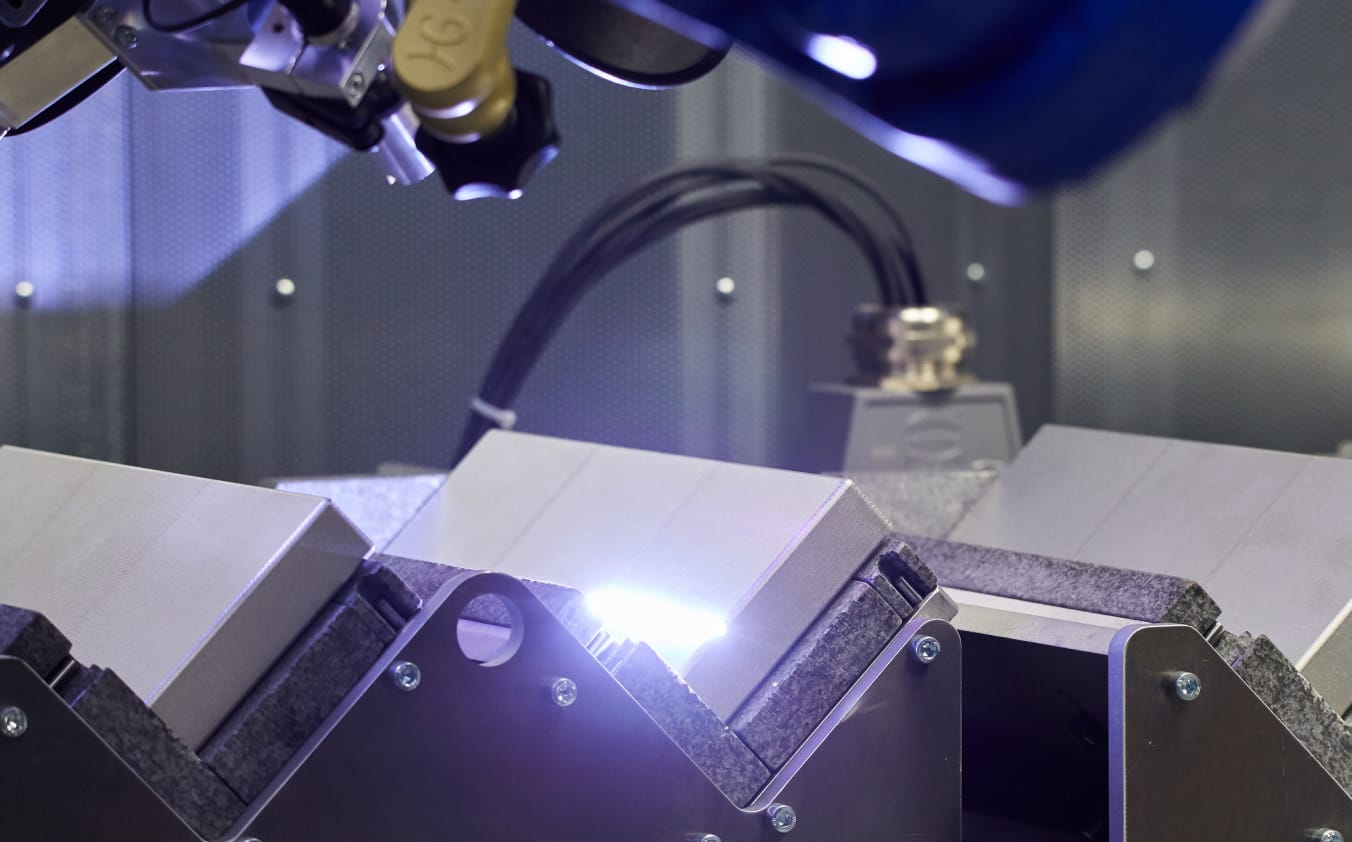

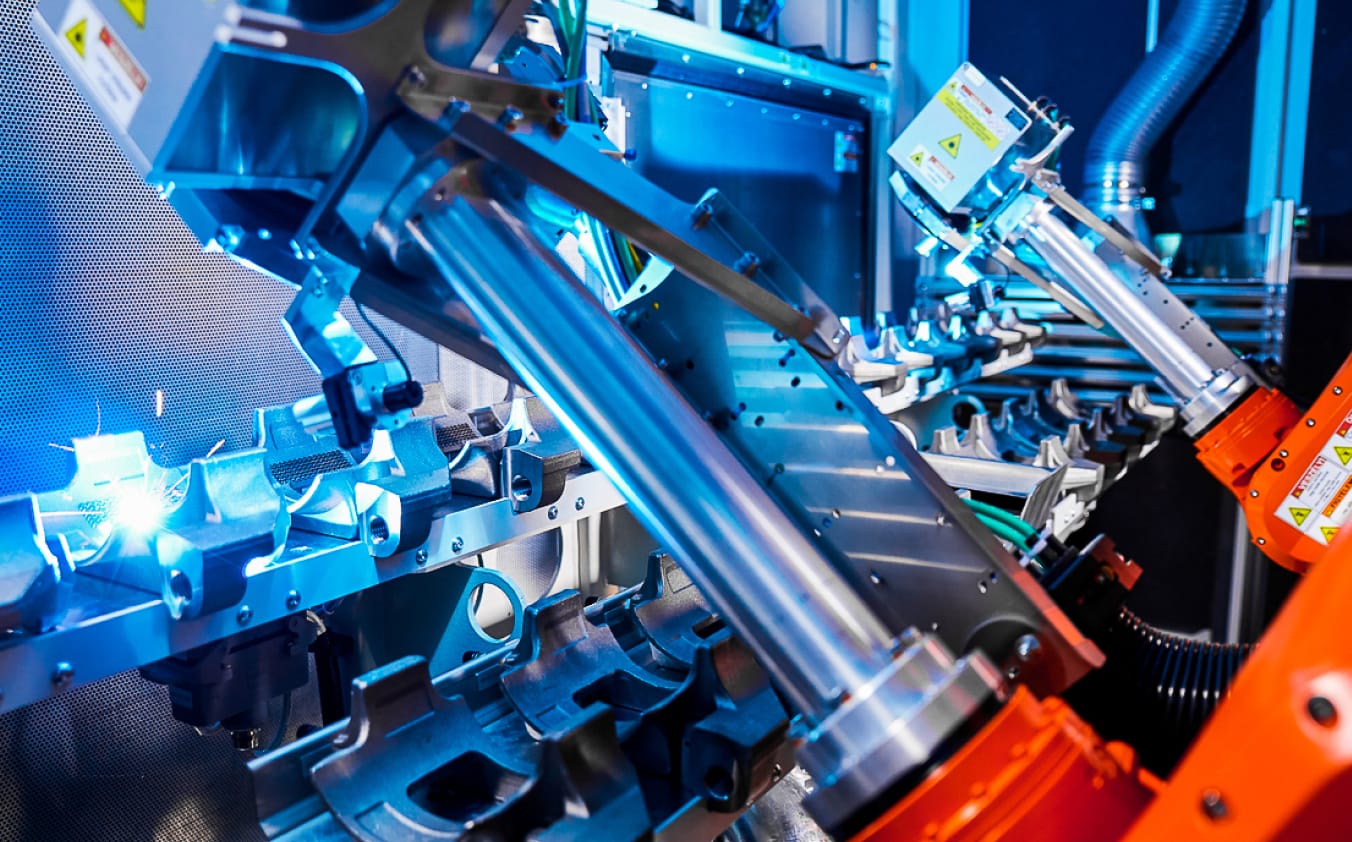

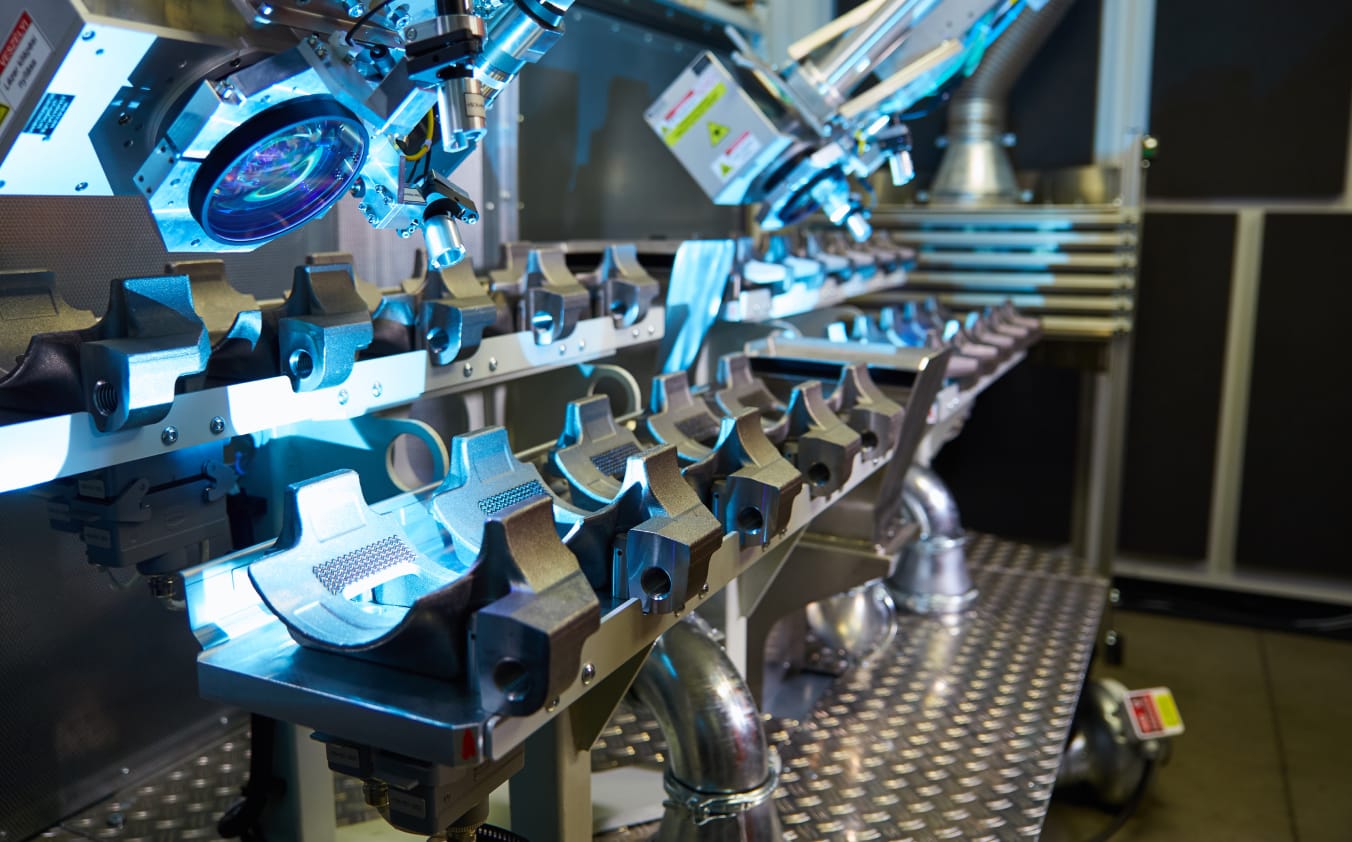

Automated Laser Cleaning Systems

Integrated into production lines or robotic cells for high-precision, high-volume tasks:

Manufacturing & Metalworking

- Weld seam preparation and oxide removal

- Paint and coating removal

- Surface activation for painting, bonding, or powder coating

Rubber Industry & Mold Cleaning

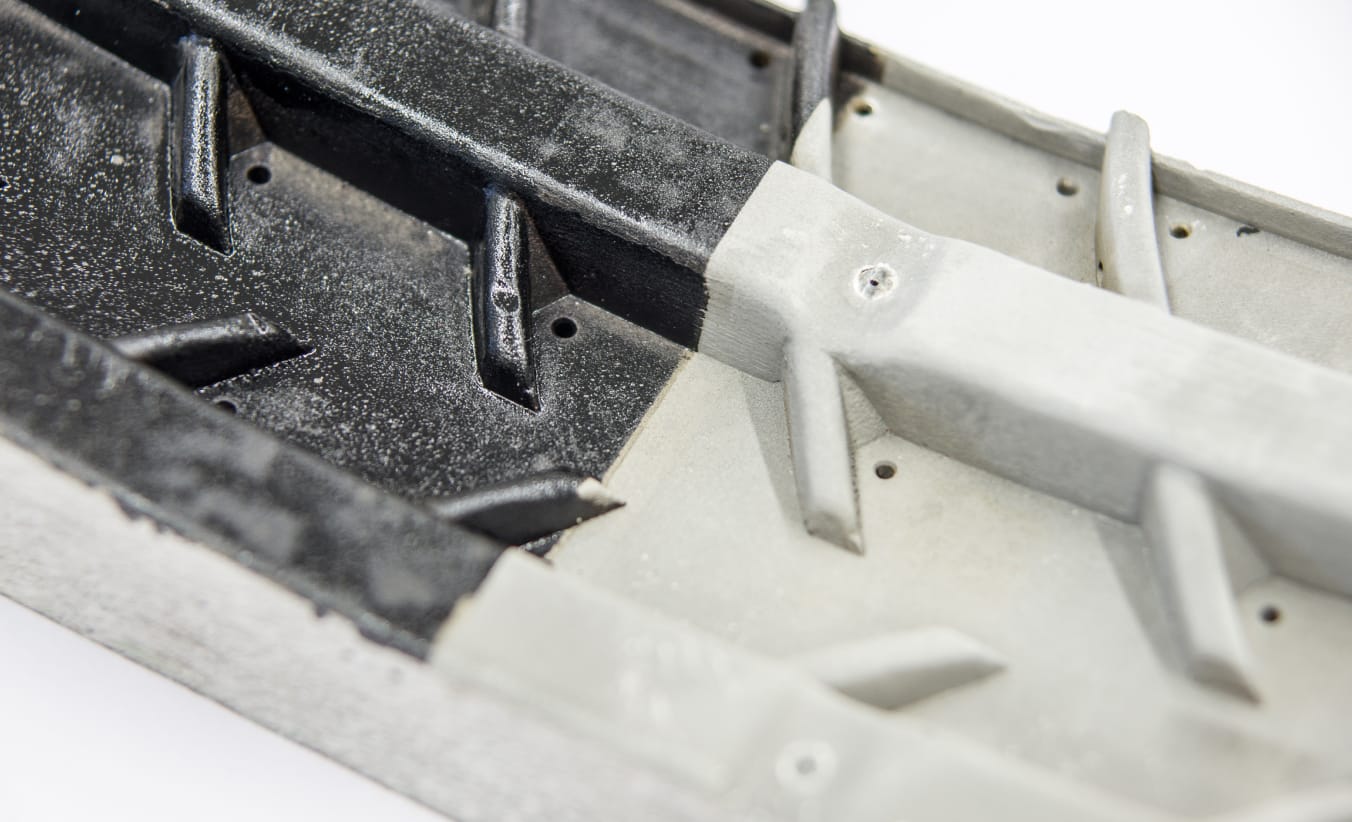

- Cleaning of tire molds and injection molds

- In-situ cleaning directly inside the press

Aerospace

- Bonding surface preparation

- Refurbishment and maintenance of high-value components

Electronics & Semiconductor Industry

- Precision cleaning of smallest contaminants on sensitive components

Energy & Power Generation

- Turbine blade and mold cleaning

- Decontamination in nuclear or high-safety environments

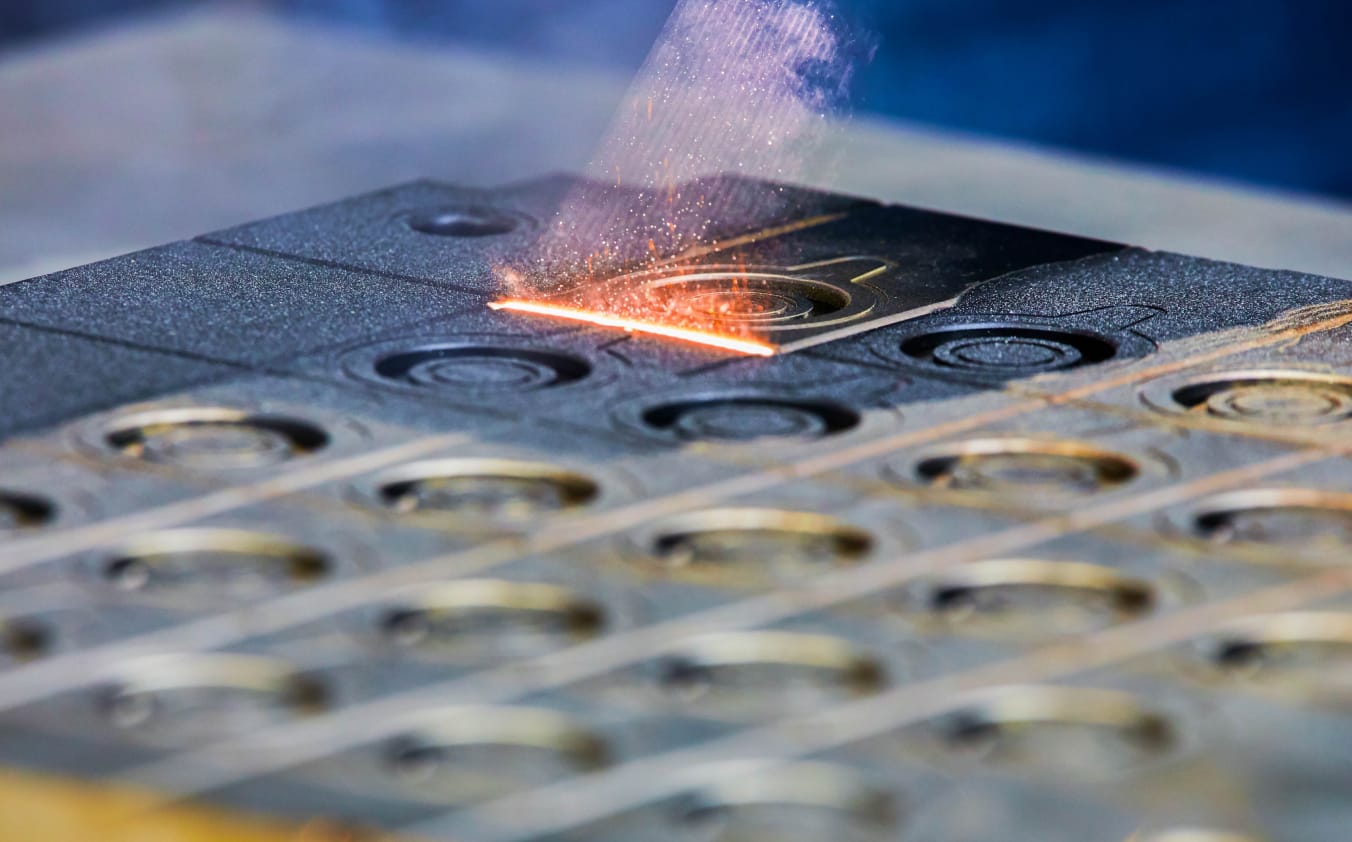

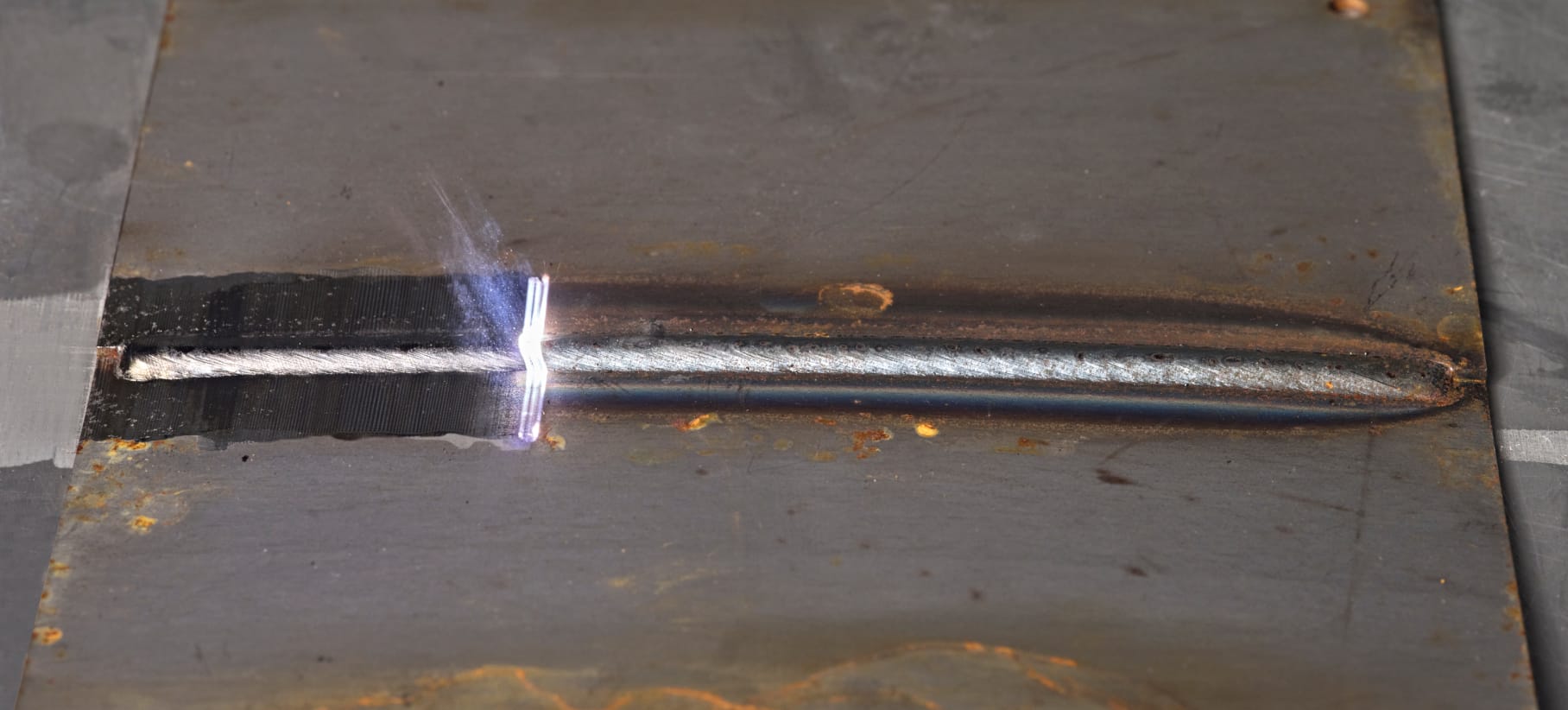

Cleaning Surfaces with Laser – How it works

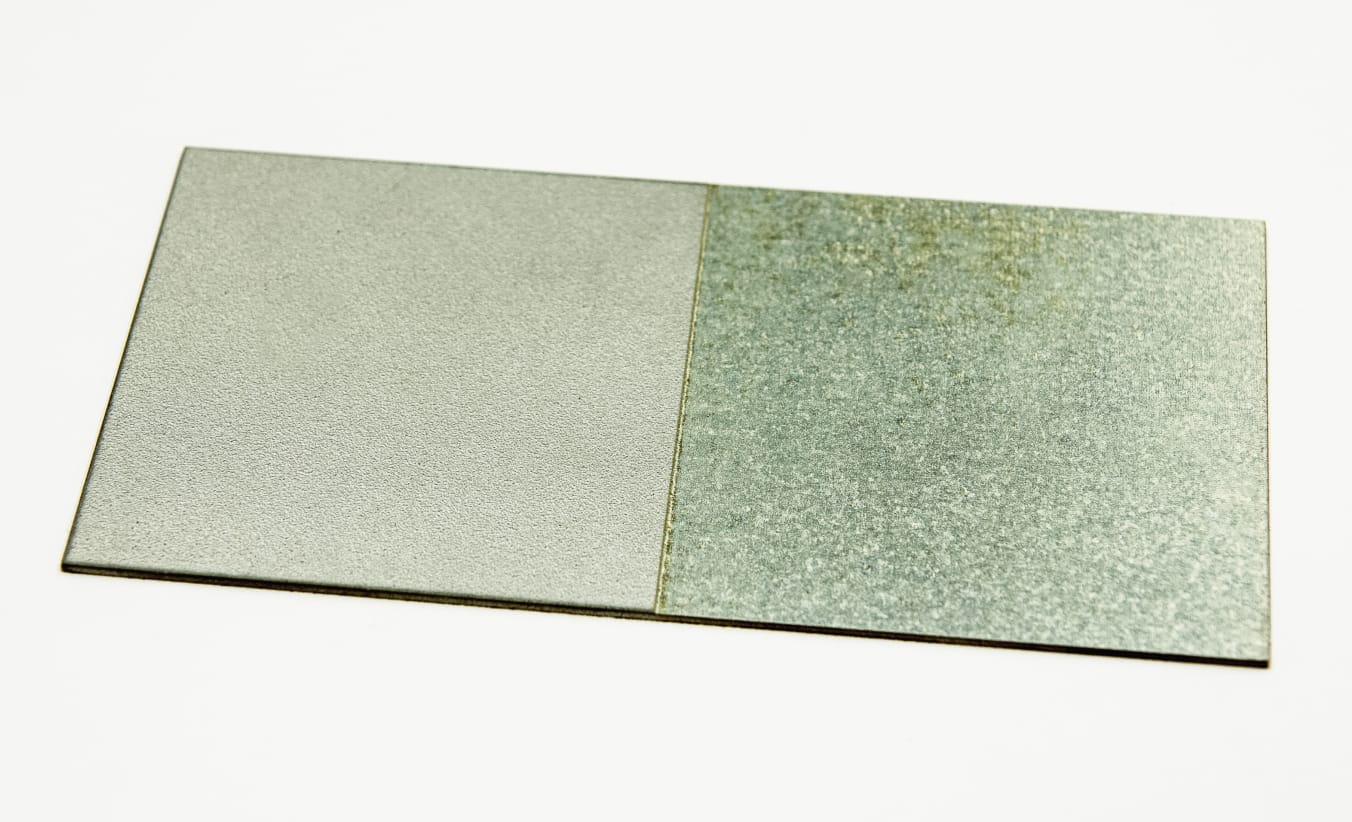

Laser cleaning uses a focused laser beam that causes surface contaminants like rust, paint, or residue to absorb the energy, evaporate or break apart and lift off – while the base material remains unaffected. The method is highly precise and localized, perfectly suited for delicate components and intricate surfaces. To ensure thorough and even cleaning, the laser beam is moved across the surface using a scanning system, typically with galvanometer scanners (galvo heads). These fast-moving mirrors direct the beam in controlled patterns –such as lines – covering the target area efficiently. The scan speed, beam intensity, and pattern are all adjustable, enabling optimized cleaning for different materials and contamination levels.

Laser beam hits the surface

Our lasers emit light in short pulses in the nanosecond range. The process is gentle on the material, as the heat input to the workpiece is reduced to a minimum.

The radiation heats up the oxid layer

Our lasers work with a wavelength of approximately 1064 nm. This light is well absorbed by layers of dirt or paint, but not by the workpiece.

The surface is cleaned by blasting off the contamination

Accessories such as our extraction system remove particles directly from the workpiece and from the air, making the laser process very clean.

FAQ: Cleaning Surfaces with Laser

The purchase price of a mobile laser cleaning system varies widely, as there are so many different automated and mobile applications. To receive a tailored quotation, simply share your application with us. Our experts will recommend the most suitable system for your needs. You are also welcome to send us your samples so we can test laser cleaning directly on your substrates.

Yes. You do not have to be a designated expert in laser applications to work safely with a laser. In our safety concept we cover all critical aspects – from the right protective eyewear and efficient extraction systems to full compliance with CE certification and safety standards.

We provide personalized, practical advice for your specific application to ensure optimal safety measures and reliable, secure operation of your laser equipment.

Yes, you can! You have several options: Send us your samples for testing, bring your samples to our facility and try the cleaning yourself, or book a demo on-site at your location.

You can even rent a demo system. We’re happy to support you in finding the best solution for your needs.