LEAF technology represents a leap forward in industrial surface functionalization, merging nature-inspired design with the precision of advanced laser technology. By enabling customizable, high-performance surfaces across aviation, wind energy, and maritime sectors, LEAF delivers tangible economic and environmental advantages – fuel savings, reduced CO2 emissions, improved durability, and enhanced sustainability.

Innovative Laser Solutions for Hydro- and Aerodynamic Efficiency as well as Industrial Sustainability

Inspired by Nature – Shark Skin Technology

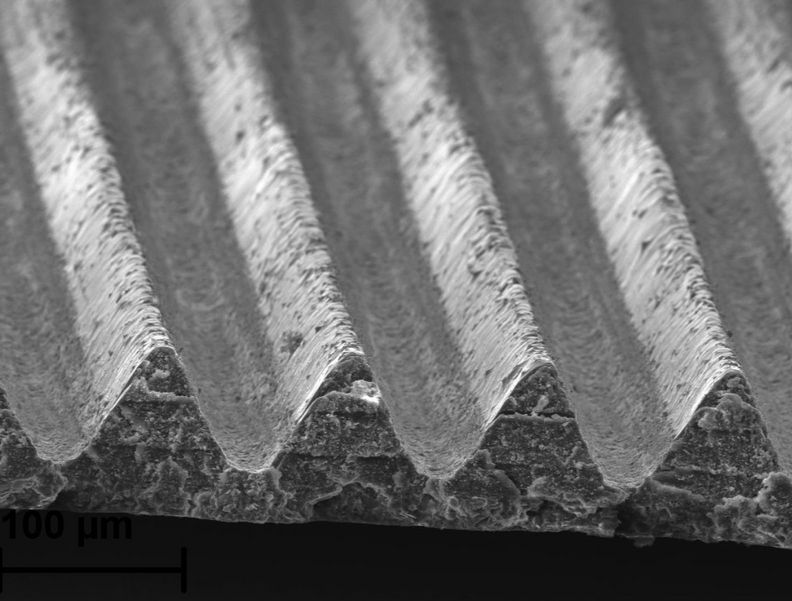

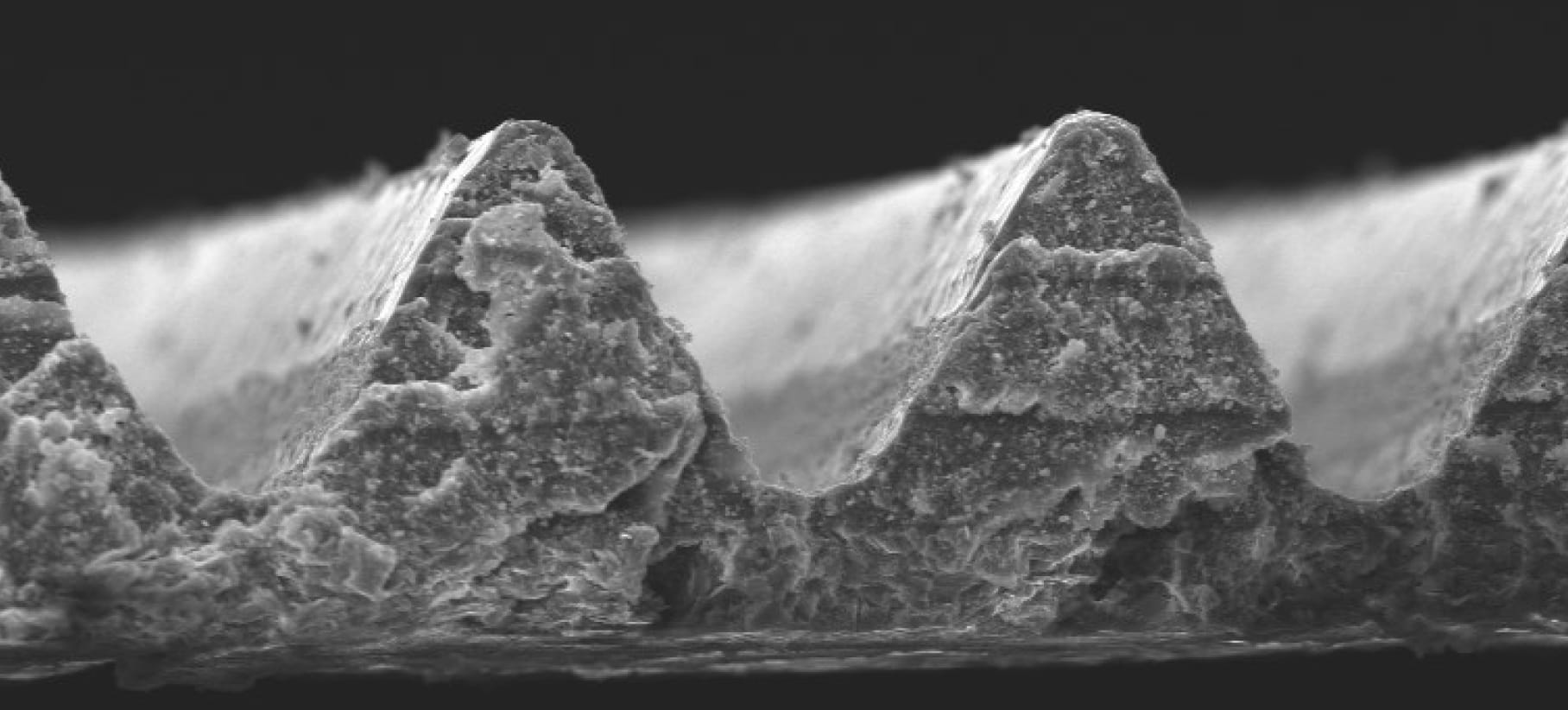

From ocean depths to cutting-edge design – shark skin shows how nature sparks technical invention. Sharks glide swiftly through the water, aided by microscopic riblet structures on their skin. These natural structures influence the formation of turbulence on the outer skin and thus reduce frictional resistance, which leads to greater efficiency in the fish's locomotion. Translating this principle to industry, surface structures inspired by shark skin have demonstrated substantial potential in improving hydro- and aerodynamic performance for engineered surfaces.

LEAF: Laser Enhanced Air Flow

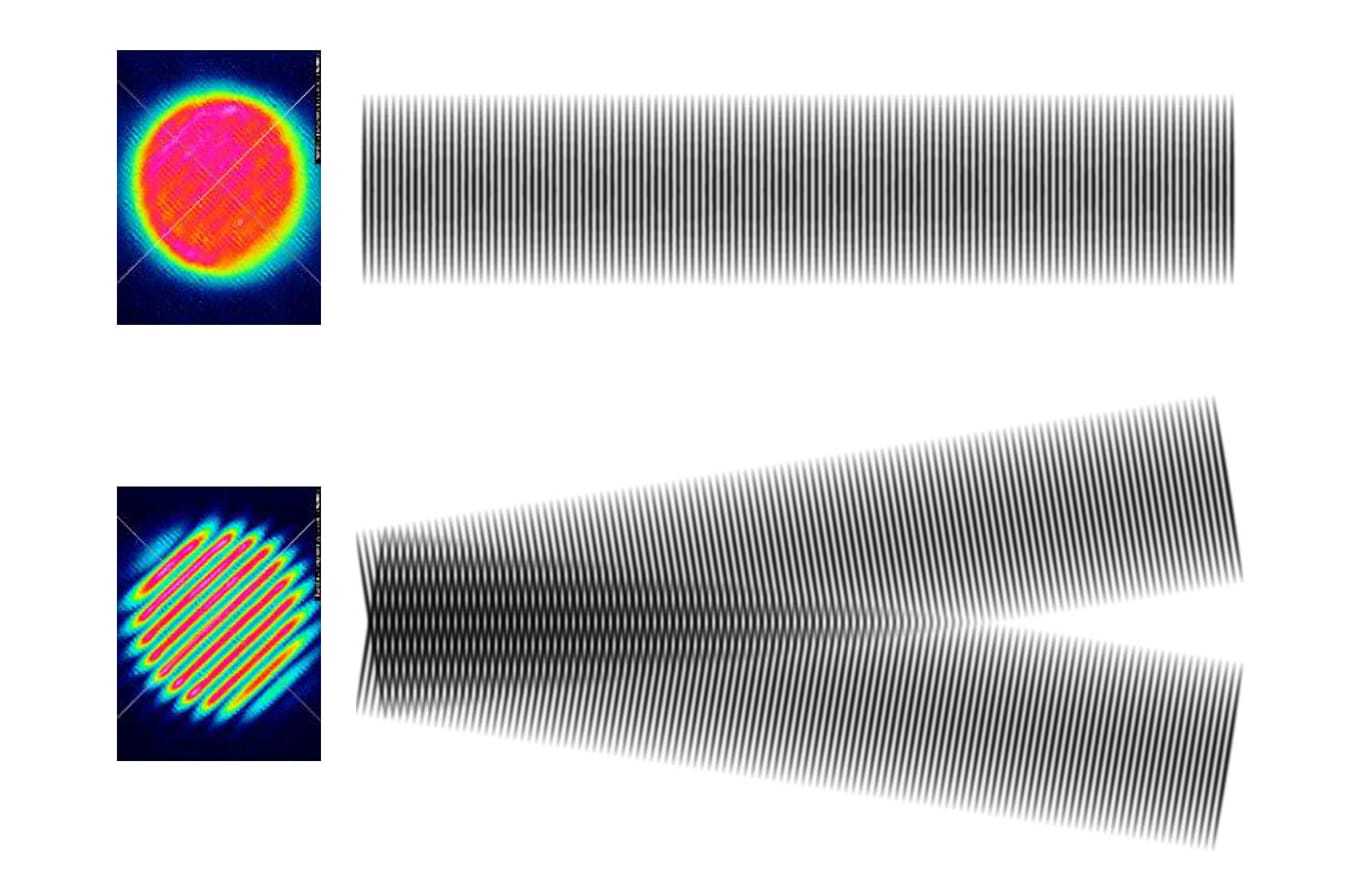

LEAF technology is a cutting-edge laser-based process for surface functionalization. It utilizes the principle of laser interference to create delicate micro- and nanostructures on material surfaces at very high speed.

Laser Interference Technology – How it works

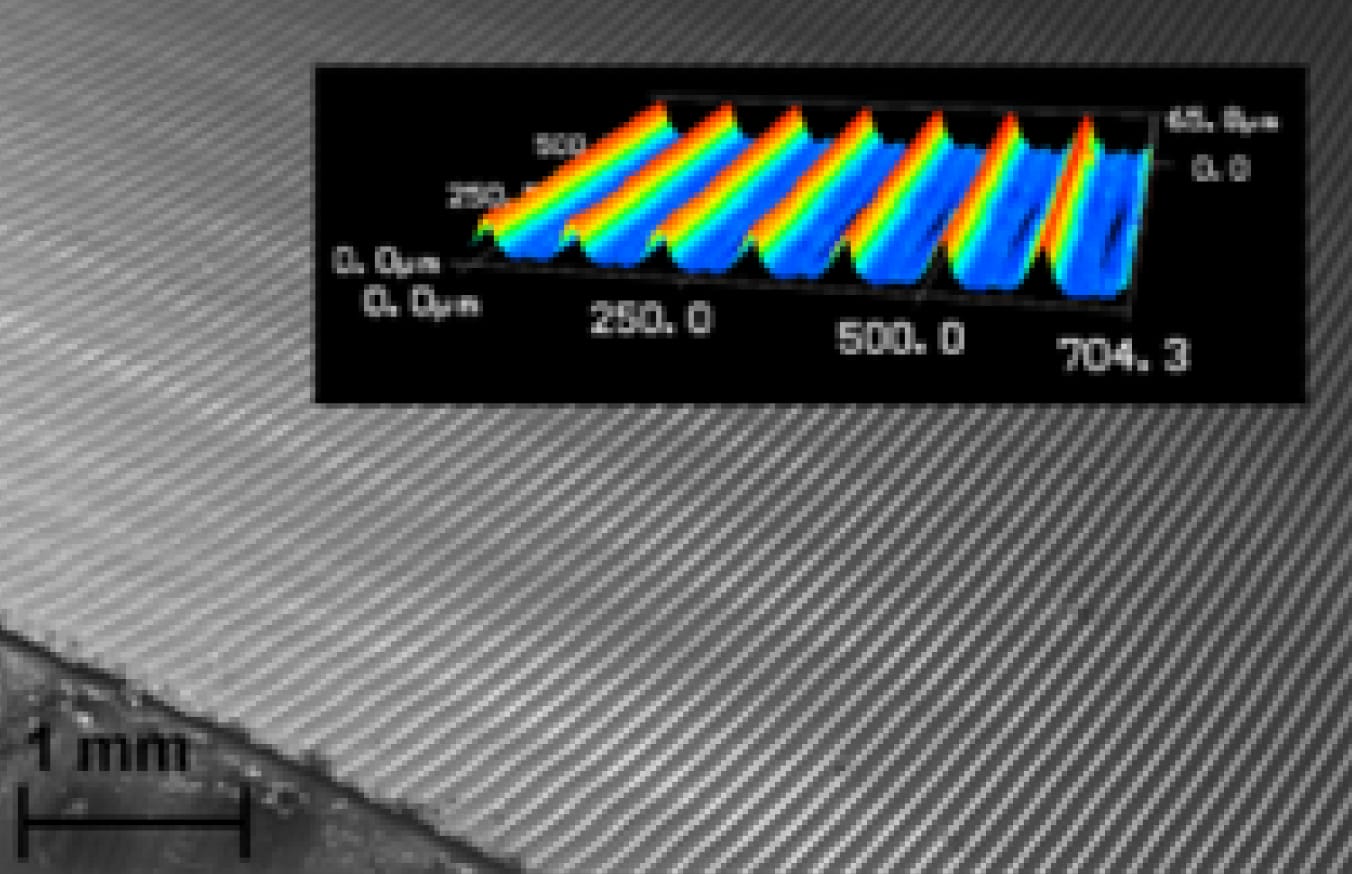

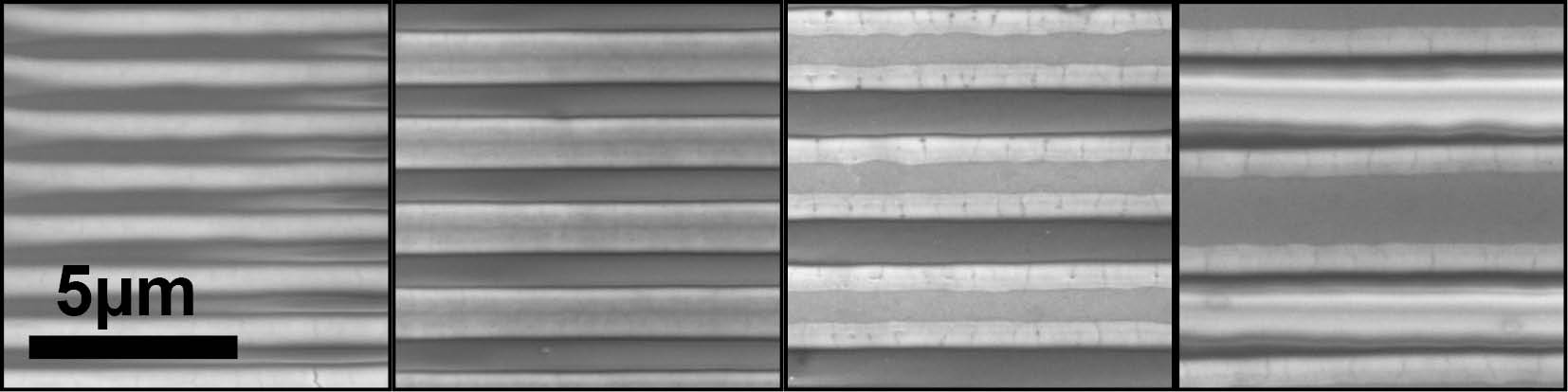

Laser interference is a physical phenomenon where two laser beams are directed at a surface, causing their light waves to overlap and interact. This interaction produces a distinctive pattern of intensity – highs and lows – that can be harnessed to modify the surface at microscopic scales. By carefully selecting the laser parameters and movements, LEAF can create specific structures directly in films or painted surfaces. LEAF technology enables processing of up to 1 m² per minute when using two laser units. The result is a customized surface with the special property of reducing surface friction caused by movement by up to 10%. A major advantage is that LEAF can be applied to materials that are already certified and proven in their application. This creates a robust functionalization that is both a scalable and environmentally friendly solution and improves product performance.

Applications of LEAF Surface Functionalization

Aviation: Fuel Savings and CO2 Reduction

Fuel costs are a substantial part of the operating costs in aviation. At cruise altitude, roughly 40-50% of the fuel consumption is used to overcome surface friction. Aircraft surfaces, from wings to fuselage, can be functionalized using LEAF to replicate the hydrodynamic advantages of shark skin and translate them into aerodynamic efficiency. The laser-induced structures reduce surface friction, leading to measurable fuel savings and lower carbon dioxide emissions.

- Typical fuel savings per aircraft per year: up to 3%

- Annual cost reduction per aircraft with only a 1% reduction: Over 200.000€ per year.

- CO2 emissions reduced per aircraft with only a 1% reduction: Over 1000 tons per year

With only a 1% reduction total global savings could reduce the emission of over 20 Mio tons of CO2 and save over 5 billion euro annually.

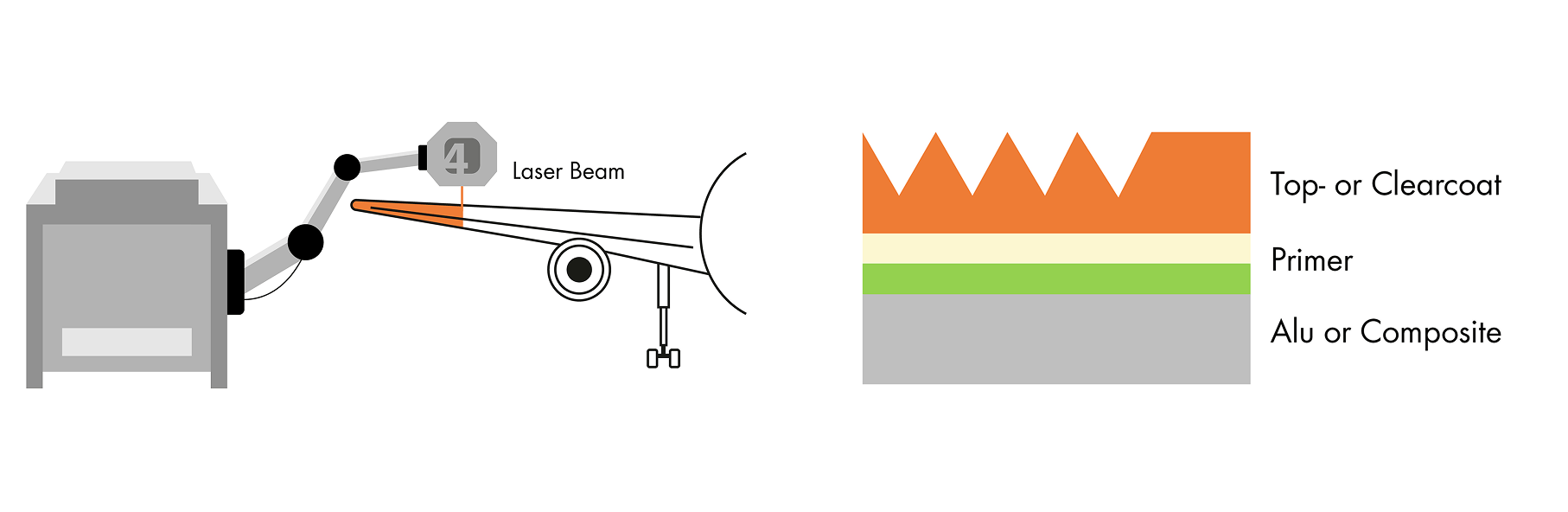

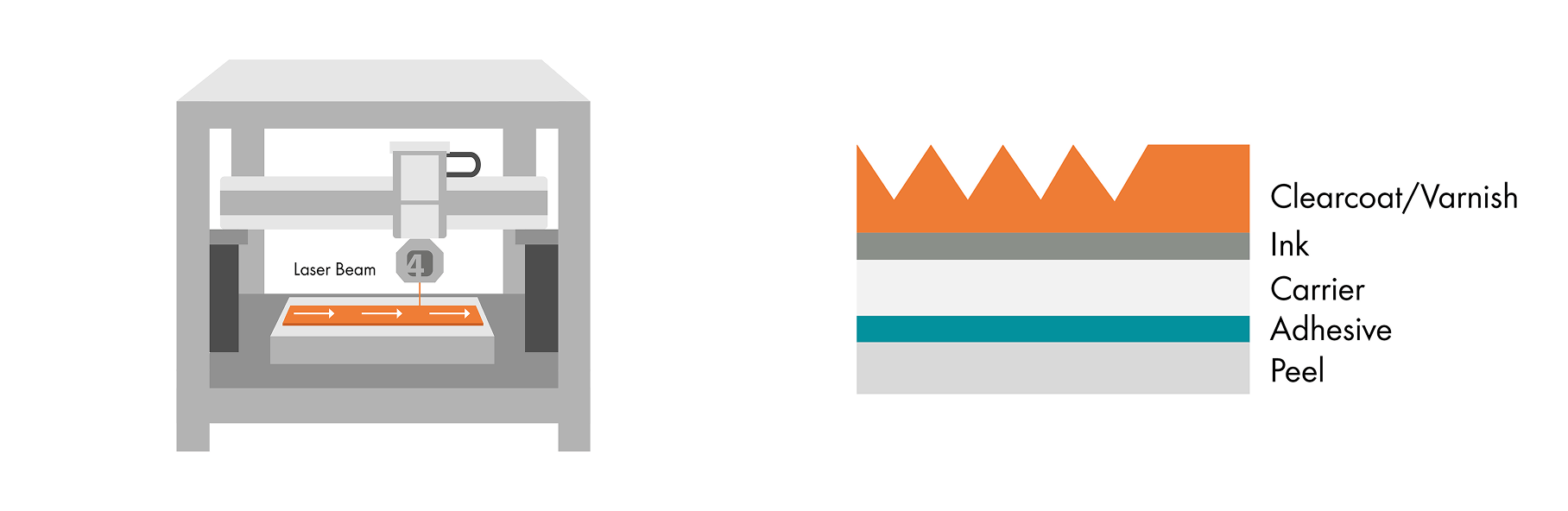

The LEAF technology can be applied either to decals as well as directly into the aircraft paint. This dual approach – functionalizing both film products and direct paint applications – provides airlines and manufacturers flexibility in integrating this high-tech surface solution into their existing maintenance and paint schedule. The operational benefits are substantial: reduced fuel consumption translates to significant cost savings and supports sustainability initiatives, aligning with global efforts to decarbonize the aviation sector.

Wind Turbines: Efficiency and Noise Reduction

Renewable energy producers are equally invested in maximizing efficiency making wind turbines ideal candidates for surface functionalization. The LEAF technology enables the creation of micro-structures on turbine blades, minimizing air resistance and increasing the amount of energy captured from wind. Literature also shows that riblets manipulate the air separation between air and turbine blade at the trailing edge leading to reduced noise generation.

- Increase in energy output per turbine with 1%

- Projected global energy gain if applied world-wide: 30.000 GWh per year.

Maritime: Drag Reduction and Sustainability

The maritime industry, facing rising demands for fuel efficiency and environmental stewardship, benefits greatly from LEAF’s advanced surface solutions. By functionalizing ship hulls and underwater surfaces, drag is reduced, allowing vessels to move more efficiently through water.

As a leader in high-tech surface functionalization, we are committed to driving innovation and supporting partners in unlocking new levels of performance and efficiency. Whether you are seeking to differentiate your products, meet aggressive climate goals, or pioneer the next generation of industrial materials, our LEAF solutions offer the pathway to a smarter, more sustainable future.

- A fuel reduction of just 1% results in direct fuel savings of 40 tons per container ship per year

- For 90,000 transport ships worldwide, this means potential savings of EUR 2.4 billion and 200,000 tons of SOx emissions per year

Contact us today to discover how LEAF technology can transform your business and set new standards for surface engineering in your industry.

FAQ: Laser Enhanced Air Flow

The exact size of these riblet structures depends on the specific application, such as the speed of the aircraft or the density of the air. However, a typical riblet structure is approximately 50 micrometers deep. Adjustments, both in spacing and depth, can be made to optimize performance based on operational conditions.

LEAF technology is fundamentally designed for polymer coatings. We have tested a wide range of certified top- and clearcoats and were able to create riblets structures in most of the materials. New materials can be tested easily within our laboratory facilities.

In addition to related industries such as aviation, wind power, and shipping, LEAF technology could also be used in other areas such as the automotive sector, high-speed trains, and motorsports.