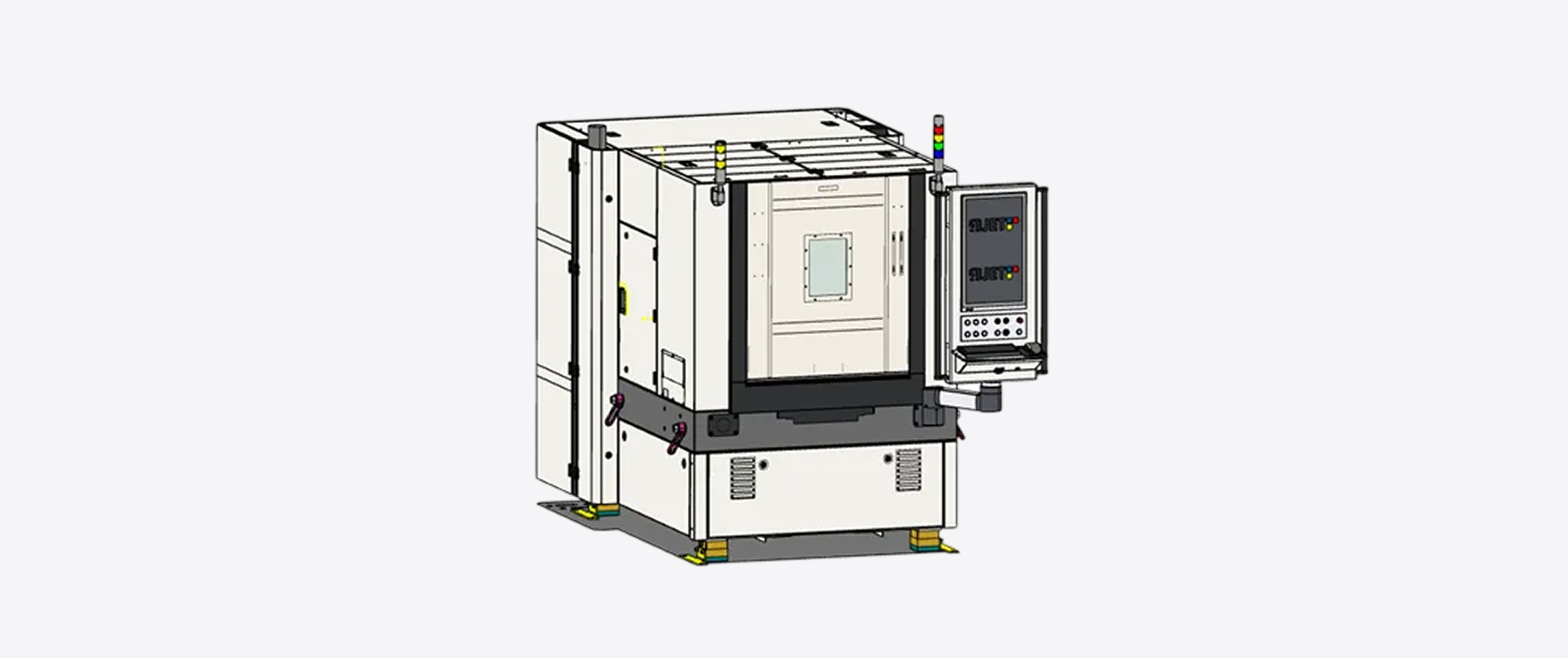

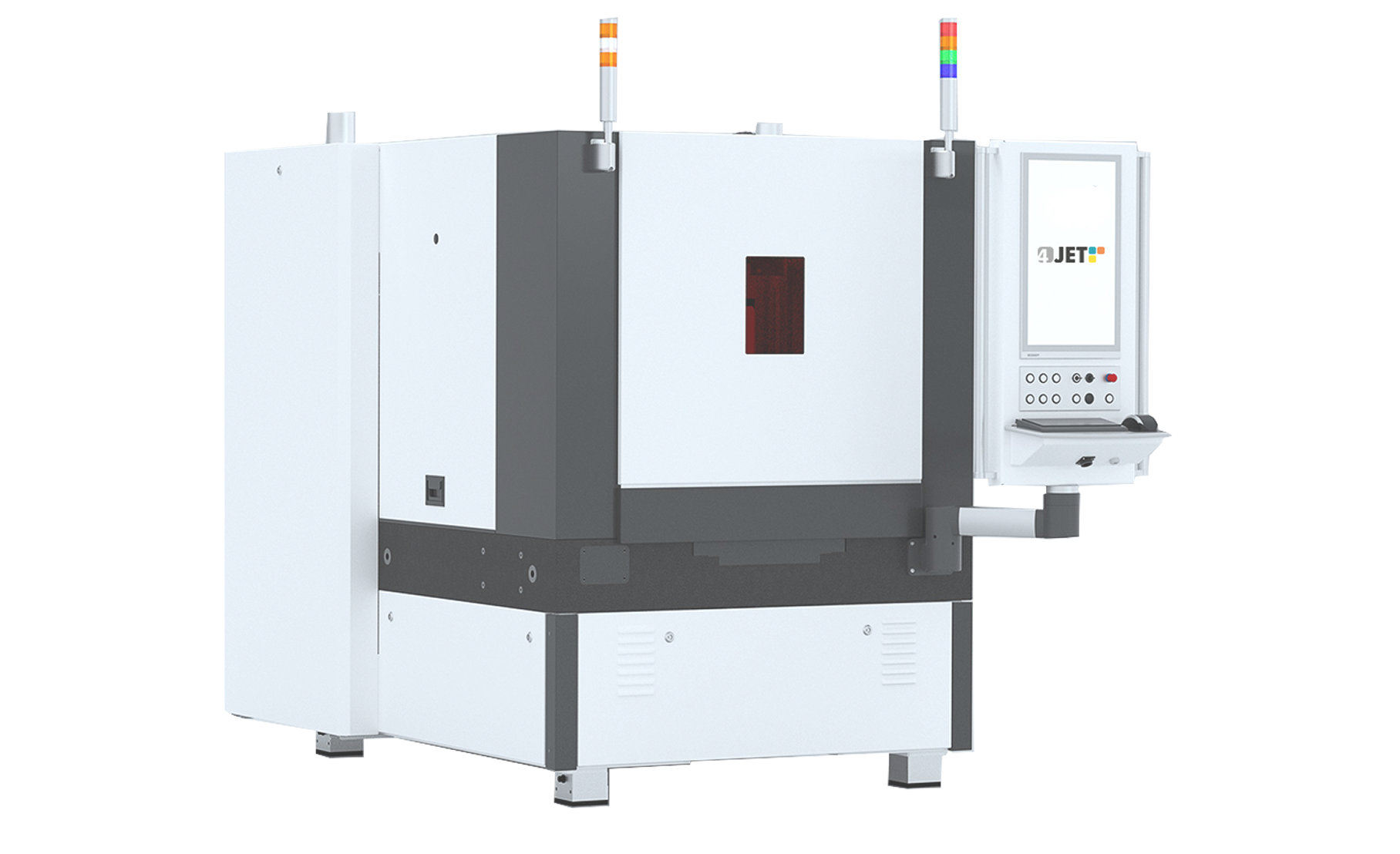

PEARL 500X – The All-in-One Solution for Precision Glass Processing

The PEARL 500X is a versatile laser system for processing glass wafers, thin glass, coated substrates, and other brittle materials.

The platform combines multiple process steps – nanoPerforation, thermal separation, laser drilling, and marking – making it the ideal solution for research and development, pilot lines, and flexible production environments where maximum precision and process versatility are required in a compact footprint.

The platform is built on an ultra-stable granite gantry with linear motor axes and is designed for continuous industrial operation. By integrating multiple process heads into one system, it reduces floor space requirements, production line complexity, and investment costs.

- Glass wafers for MEMS and sensing

Processing glass wafers for microelectromechanical systems (MEMS), pressure sensors, accelerometers, and other sensing technologies.

- Micro-optics & Wafer Level Optics (WLO)

Structuring and singulation of micro-optical components at wafer level, including stacked wafers for complex optical systems.

- Macro- & micro-optics/molded optics

Precision processing of optical components in various sizes, including molded optics for industrial and medical applications.

- Meta-surfaces for AR and wearables

Structuring glass for advanced optical functions, for example AR glasses, head-up displays, and wearable devices.

- Rotary & linear encoders

High-precision structuring and singulation of glass and silicon components for position and motion sensing in automation.

- R&D/prototyping

Precision drilling, structuring, and dicing for research, sample production, and small series – easily adaptable to new materials and designs.

- Dicing of SiC and glass

High-precision dicing of silicon carbide, hardened and non-hardened glass – even with challenging geometries and coatings.

- Dies with coatings & microstructures

Processing dies with functional layers, microstructures, or sensitive surfaces – without damage.

- Color filter and filter technologies

Structuring and dicing of color filters and optical coatings for cameras, sensors, and display technologies.

- Glass in semiconductor applications

Processing glass as a carrier material or optical interface in modern semiconductor applications for example for co-packaged optics.

- Bio- & medical technology

- Next Generation Sequencing (NGS): Structuring glass for DNA analysis platforms.

- Lab-on-a-chip & microfluidics: Fabricating microfluidic channels and structures in glass.

- DNA drug discovery: Glass structures for drug research and screening.

- Microscopy accessories: Slides and coverslips, including those with biofilms or functional coatings.

- Cuvettes & flow cells: Precision glass processing for optical measurement cells and flow chambers.

Highlights of the PEARL 500X Platform

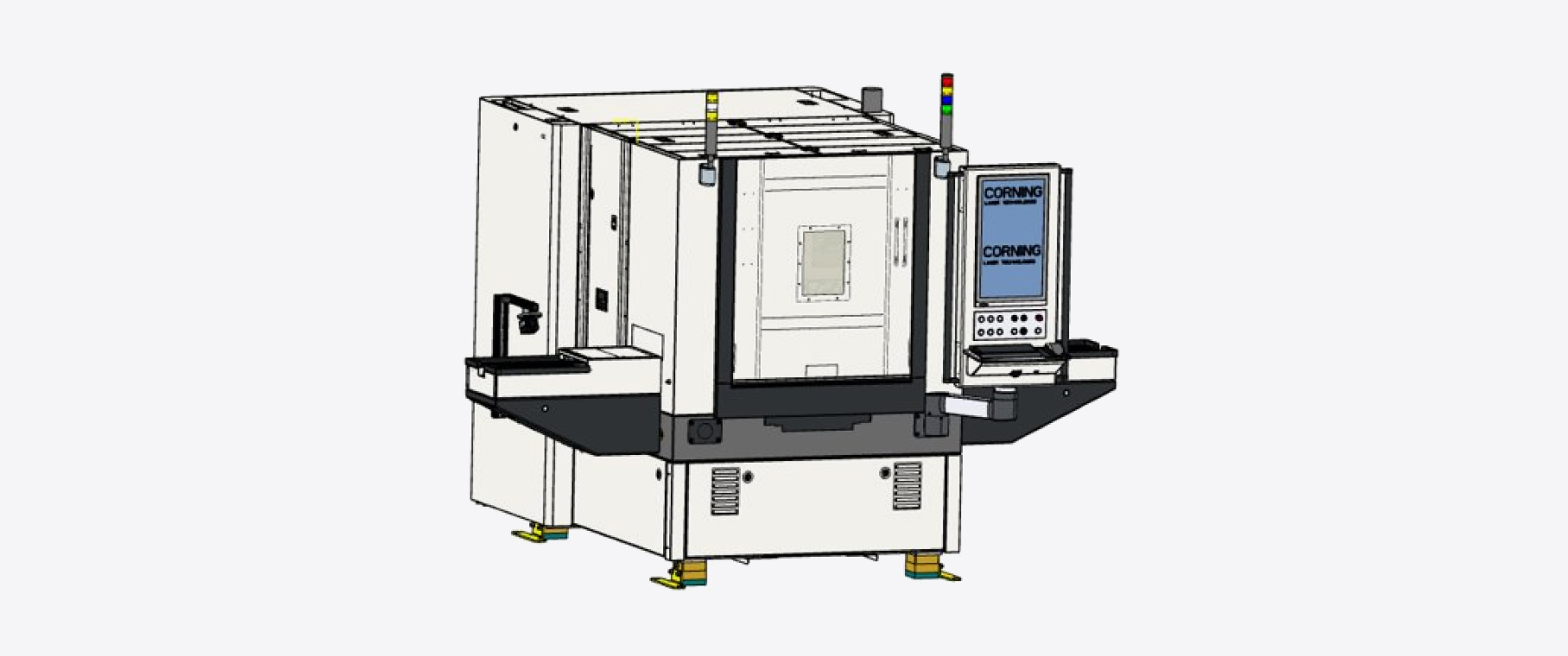

PEARL 500X – Variants & Process Options

The PEARL 500X can be equipped with up to three process heads simultaneously, selected from these specialized modules:

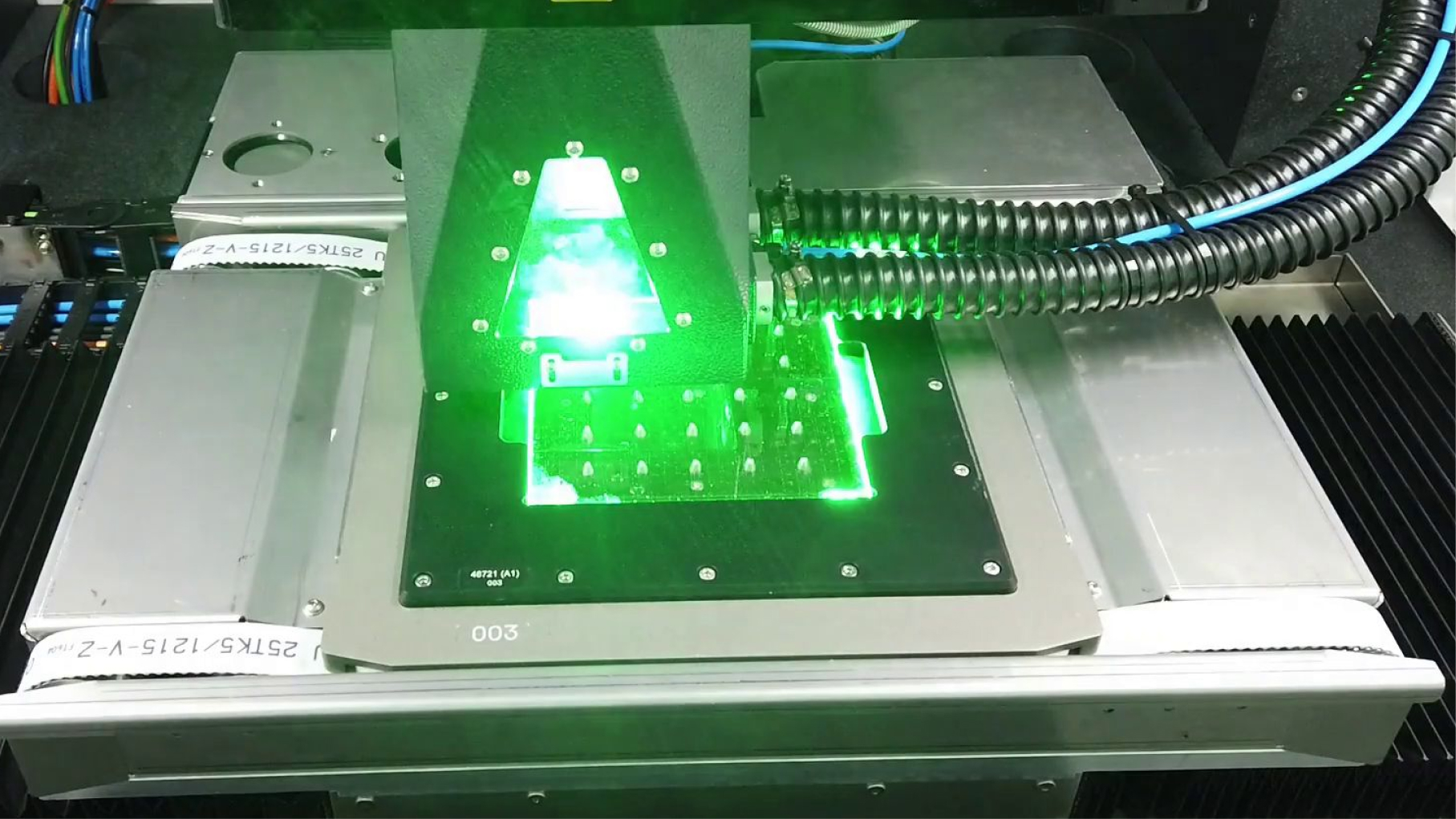

nanoPerforation process head

Our patented and exclusive glass cutting head with Bessel beam technology

Enhanced nanoPerforation process head

Improved beam guidance and higher processing speed for demanding applications and higher throughput

Separation process head

Thermal separation without mechanical stress, directly integrated – no second system required

Enhanced separation process head

For thicker substrates or complex separation geometries, with improved edge quality and minimizing impact on coatings

Scanner-based drilling head

For high-precision laser drilling, e.g., in microfluidics or sensing

Marking process head

For permanent part marking of components such as 2D codes, serial numbers, or process data

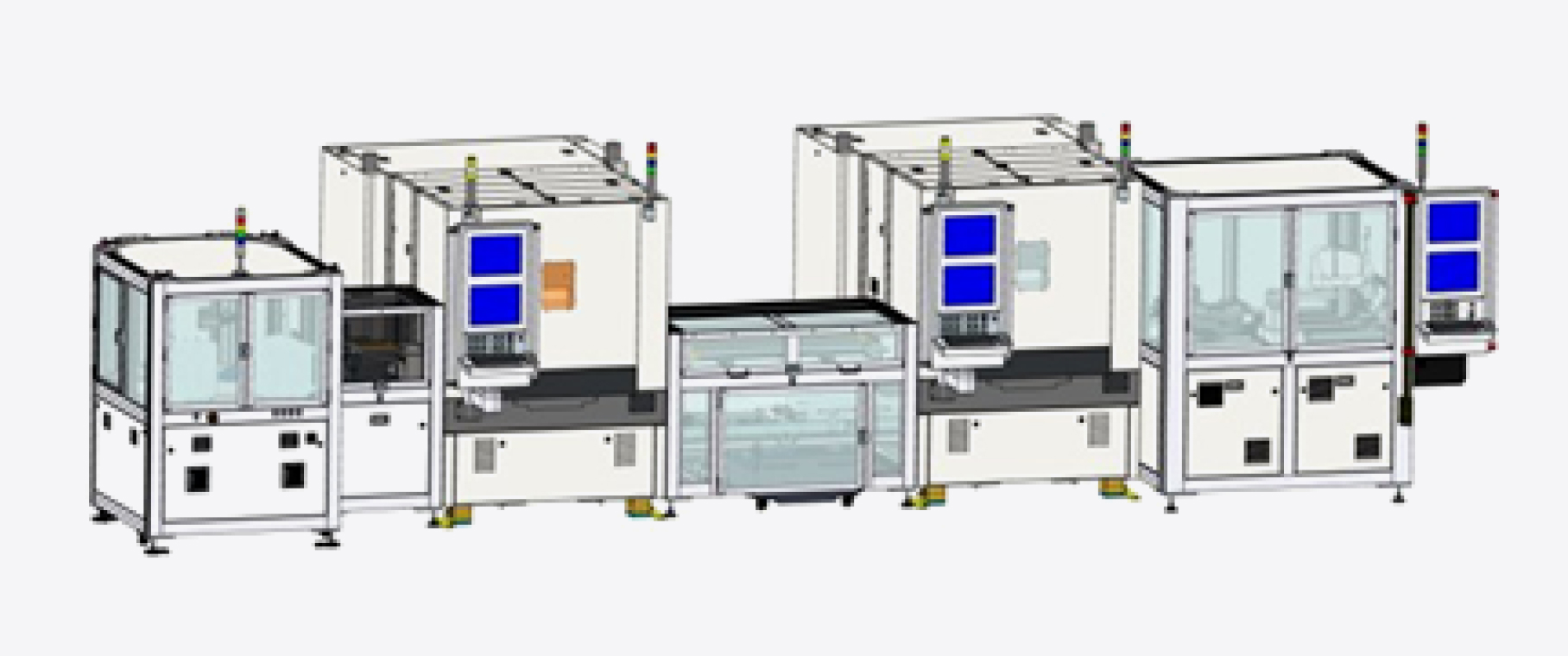

Various Configurations Are Possible

Technical data for the PEARL 500X

| Category | Feature | Specification |

|---|---|---|

| System size & weight | Dimensions (W×D×H) | 1650 mm × 2200 mm × 2650 mm |

| With supply rack | 3200 mm × 2200 mm × 2650 mm | |

| Weight | ~3,800 kg | |

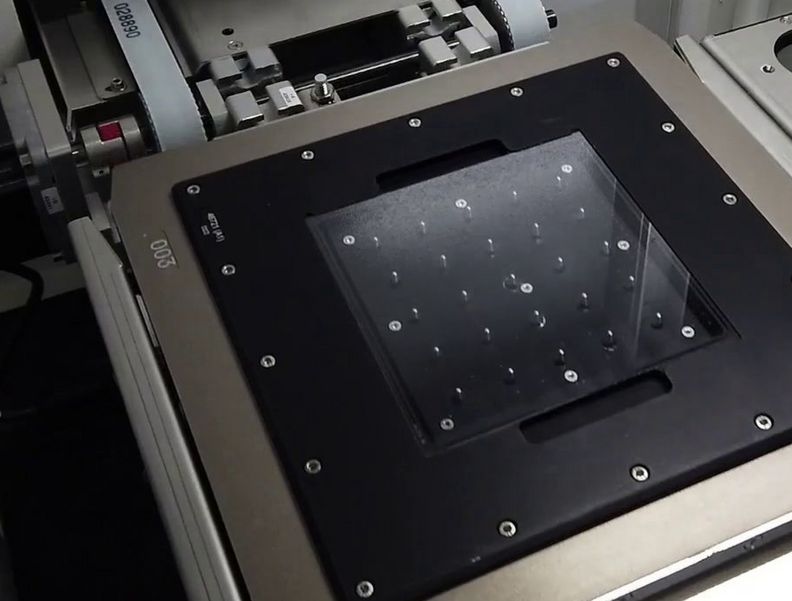

| Axes & movement | Machining area | 300 mm × 300 mm |

| Feed speed | up to 1000 mm/s | |

| Acceleration | up to 10 m/s | |

| Dimensional accuracy | < 2.5 µm + 7.5 × 10⁻⁵ × L | |

| Repeatability | ≤ 2 µm | |

| Software & operation | HMI | Touchscreen-based user interface |

| CAD import | DXF, simple job configuration | |

| Vision system | Developed in-house cVision interface with fiducial and edge detection | |

| MES connection | SECS/GEM (optional) | |

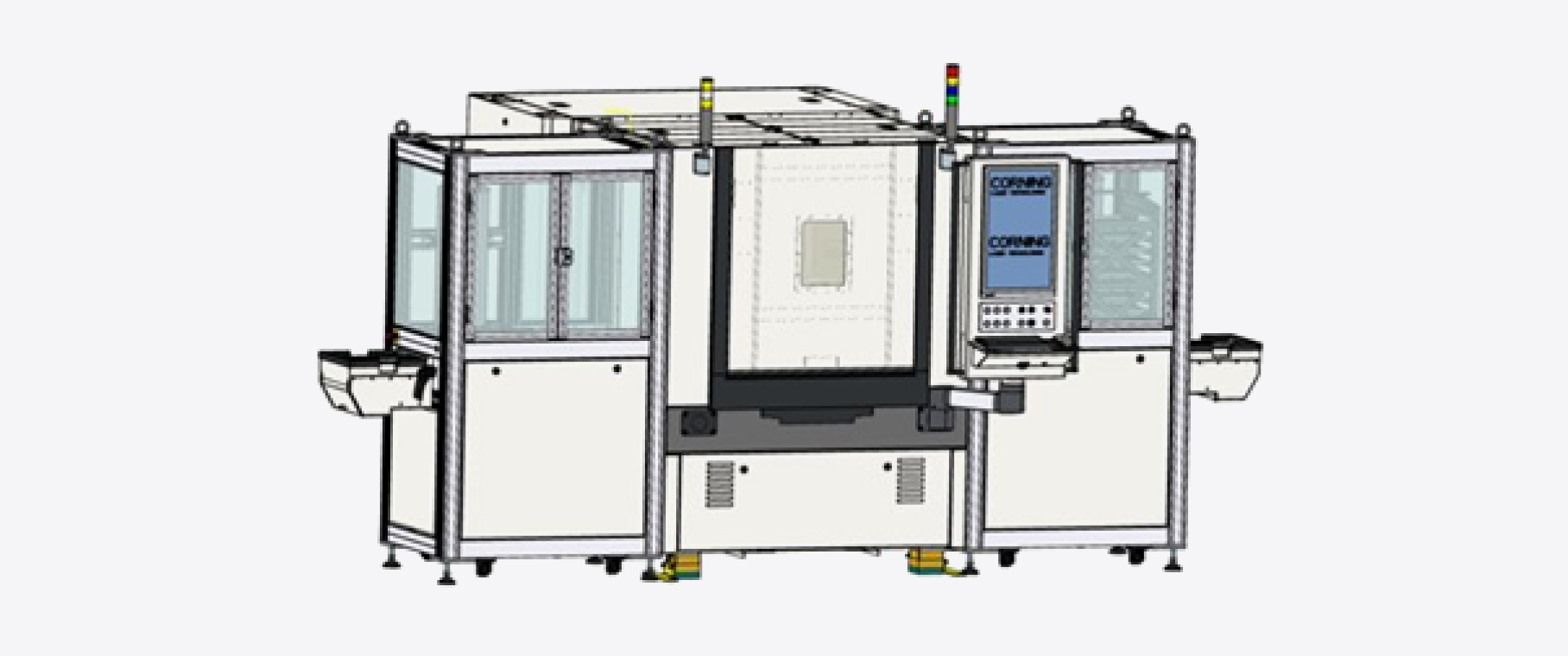

| Automation | Belt loading system | Semi-automatic with inlet/outlet ports |

| Wafer handler | Fully automatic for 2 cassettes | |

| 2D code reading | Can be integrated |

Available options

- Enhanced nanoPerforation

- Enhanced separation

- ns, ps, or fs drilling process

- 2D code marking

- Height sensor

- Beam profiler

- Ionizer

- Humidity booster

- Earthquake protection

- Transformer

- Chiller (PCW)

- Remote Access (GenuBox)