JETLASER

Manual and Mobile Laser Cleaning System

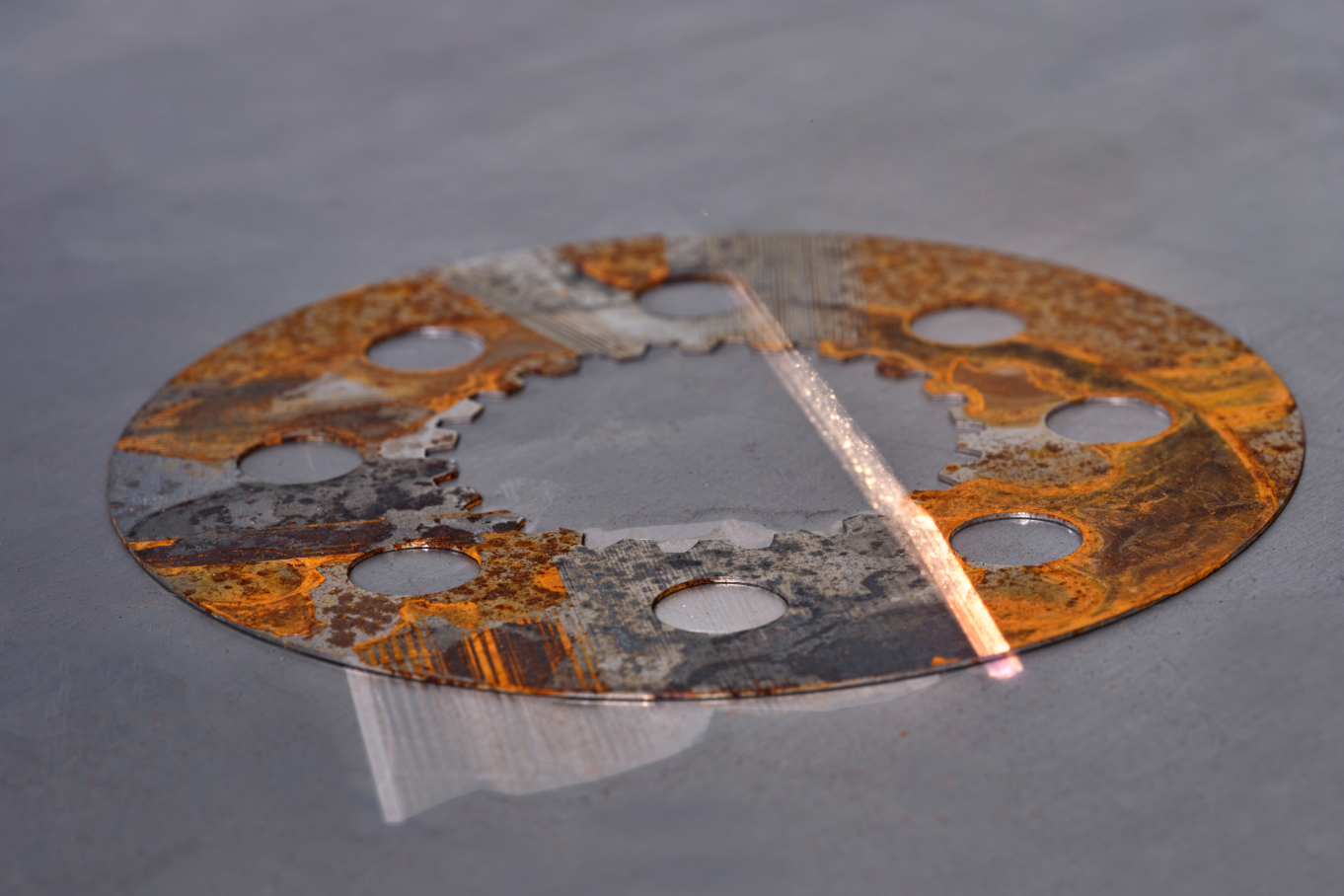

Laser technology is a powerful tool for industrial surface cleaning, offering safe, efficient, and contact-free removal of rust, paint, coatings, and other contaminants. Designed for maximum mobility, precision, and environmental friendliness, it outperforms traditional methods like dry ice blasting or sandblasting – without chemicals, secondary waste, or abrasion.

What is Mobile Laser Cleaning?

Mobile laser cleaning is a dry, contactless technology for cleaning, activating, or stripping surfaces using high-energy laser pulses. It is ideal for use on-site, especially in confined spaces or hard-to-reach areas.

Mobile Cleaning of Surfaces – Your Benefits in the Spotlight

Mobile Laser Cleaning – How it works

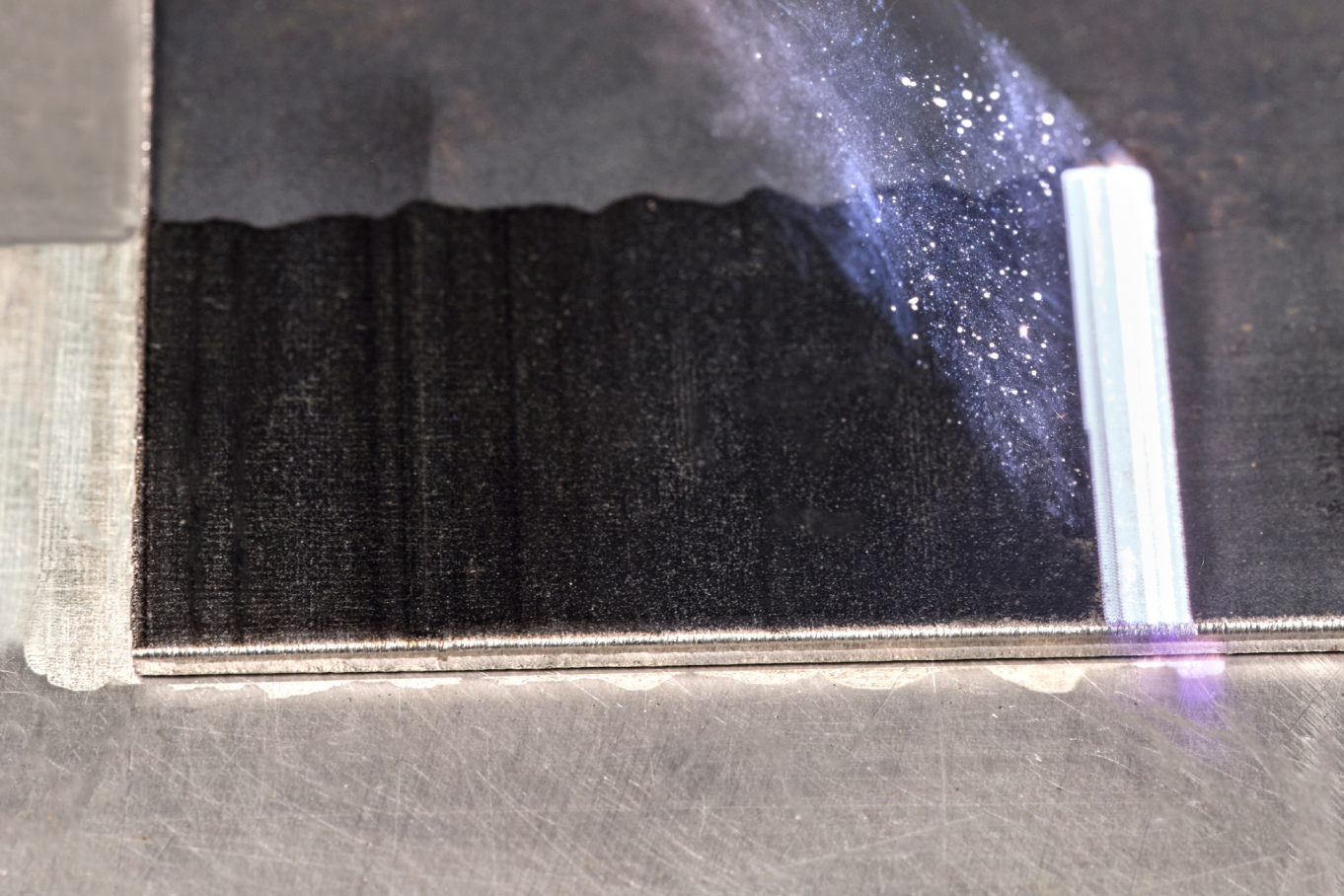

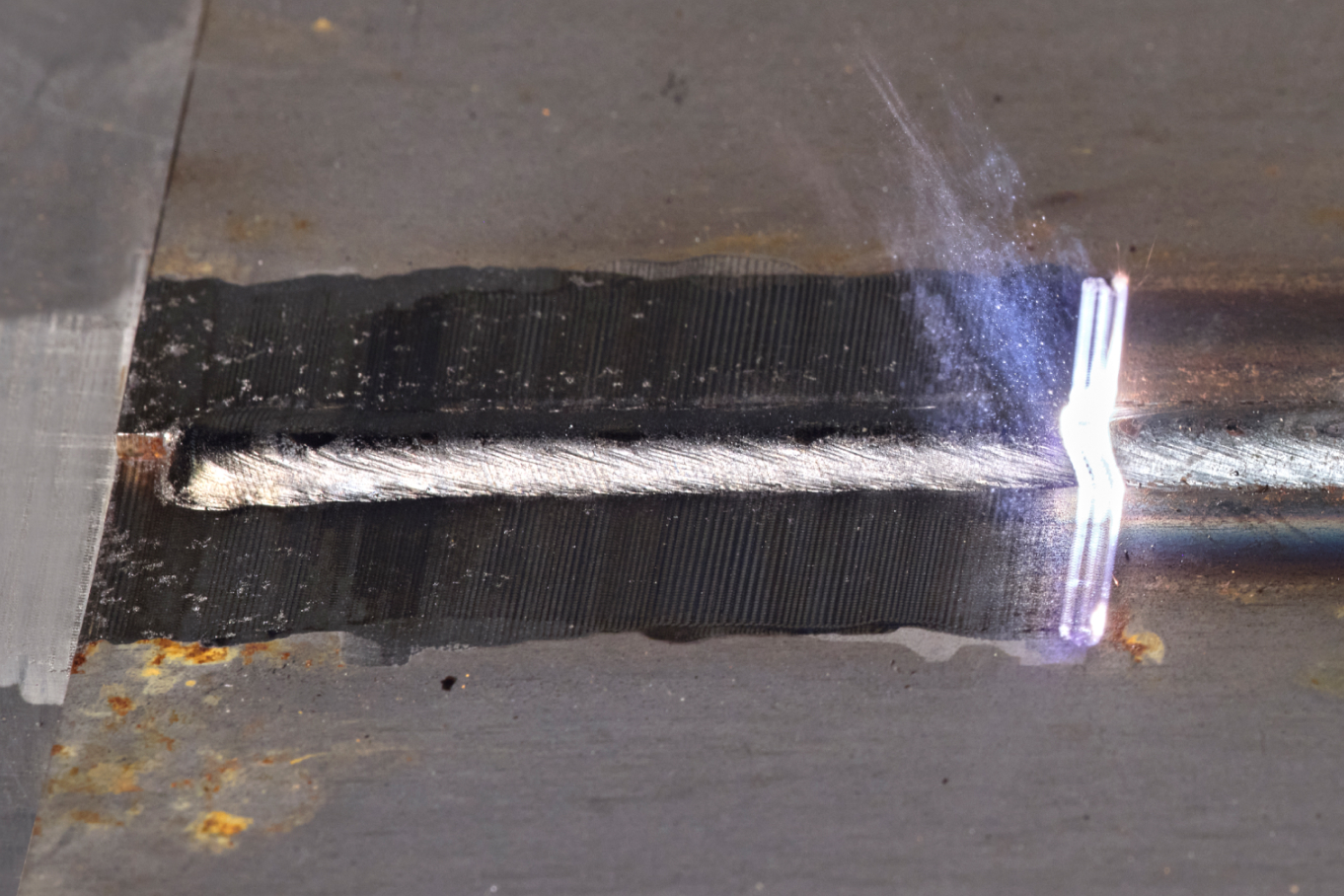

Laser pulses are absorbed by surface contaminants but not by the substrate. This enables precise and selective cleaning without damaging the base material. Thanks to the extremely short nanosecond pulses, only minimal heat is transferred to the substrate. The scanner precisely aligns the individual light pulses, creating a uniform surface ablation. To the human eye, this appears as a continuous laser line several centimeters long, which the operator guides carefully across the surface to be cleaned. Optional extraction systems ensure a clean and safe working environment.

Key Benefits of the JETLASER System

Technical Specifications

- Laser power: 500 W – 1,000 W

- Fiber length: 15 meters (longer available)

- End effector: Lightweight and ergonomic

Areas of Application Across Industries

Metal Processing:

- Rust removal

- Paint and oxide stripping

- Weld seam preparation

Molds & Rubber Industry:

- Compression and injection mold cleaning

- In-situ cleaning in the press

Restoration & Building:

- Soot removal after fire damage

- Coating removal from wood or delicate surfaces

Aerospace & Automotive:

- CDC removal

- Pre-bond cleaning

- Grease and oil residue removal

Surface Activation:

- Pre-treatment for painting, coating, or bonding

- Laser surface roughening for adhesion

JETLASER DAY – Try it Yourself

Experience the power of mobile laser cleaning live at our regular JETLASER DAY events!

Try the JETLASER yourself, clean your own samples, and see the impressive results firsthand. Our on-site experts will provide comprehensive advice and show you the full potential of laser cleaning technology.

Ready to clean smarter? No chemicals. No abrasion. Just perfect surfaces.

Contact us today to discuss your mobile laser cleaning needs, book a demo at the next JETLASER DAY, request a brochure or a technical consultation.

FAQ: Mobile Laser Cleaning

40,000 to 220,000 EUR depending on configuration. 0.50 EUR/hour operating cost.

Yes. CE-certified with operator training included.

Yes – send samples, book a demo, or rent a unit.

Rust, paint, CDC coatings, grease, soot, and more.

Yes. See JETLASER Integration.