Tire Cavity Noise Is Causing Unpleasant Driving Experiences

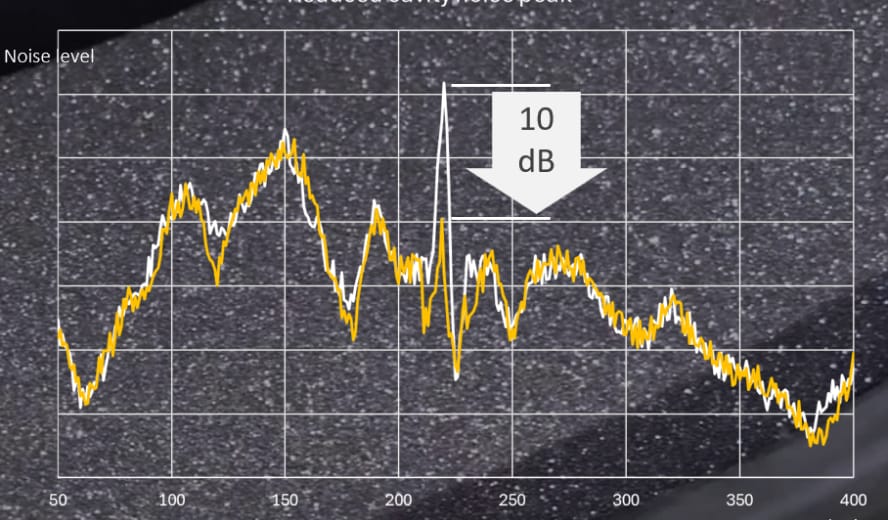

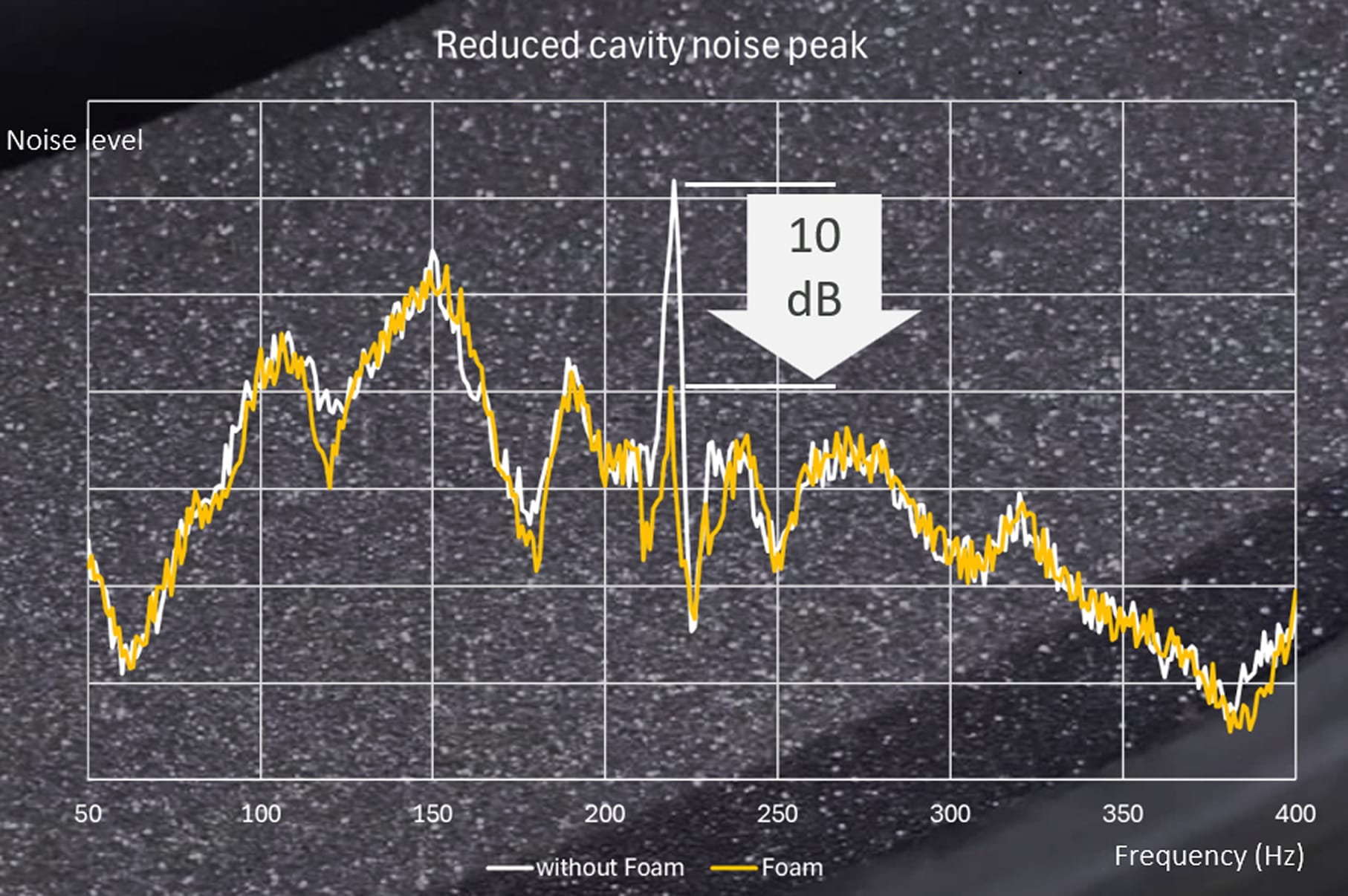

Lightweight construction and the absence of engine noise in electric vehicles make tire rolling noise more noticeable inside the cabin. Especially the so-called cavity noise peak at the tire resonance frequency is significantly more intrusive and unpleasant compared to combustion vehicles. Hence, modern electric vehicles are increasingly equipped with tires that have an acoustic polyurethane (PU) foam lining on the inside. These so-called "Silent Tires" significantly reduce noise emissions both inside the vehicle and in the surrounding environment, ensuring an improved driving experience.

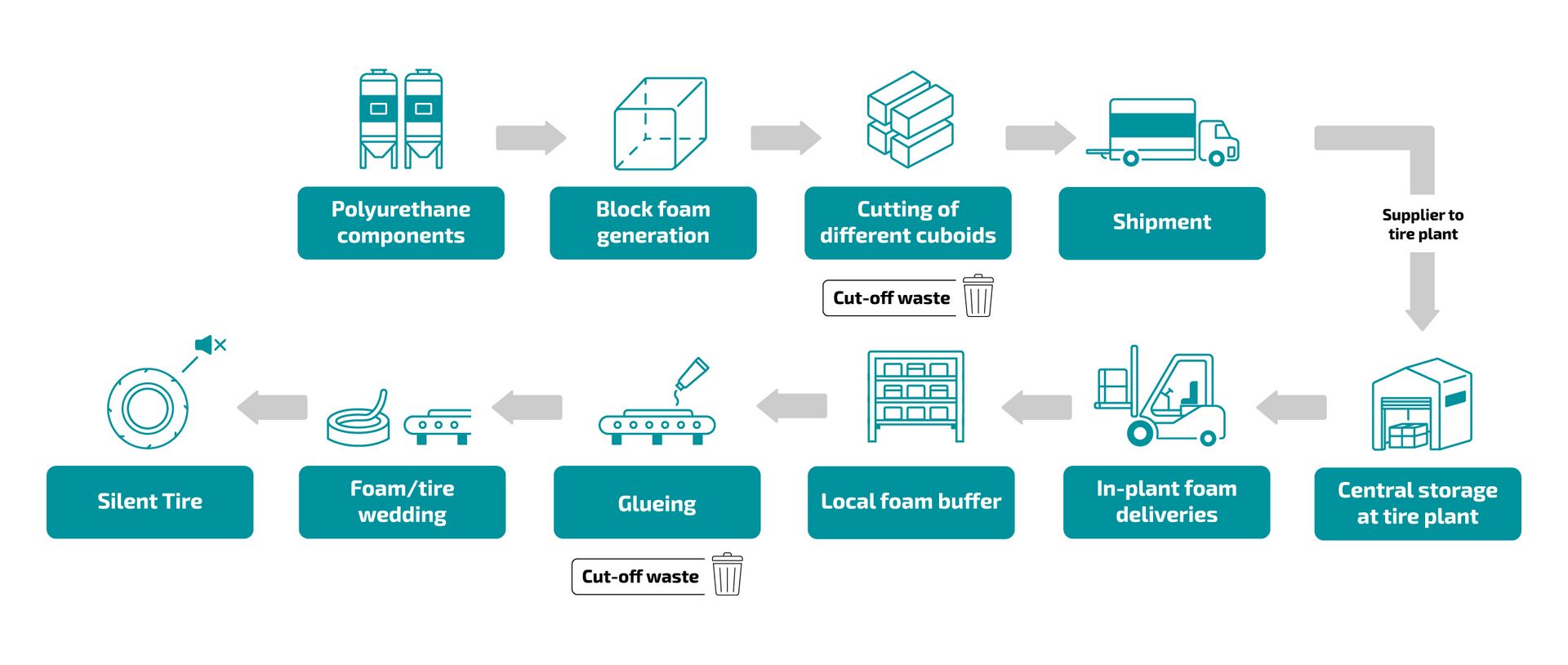

Current Foam-in-Tire Technology – A Daily Logistical Challenge

This simple solution concept presents tire manufacturers with a complex and demanding task: a second logistics line must be integrated into tire factories to transport the lightweight but high-volume foam to the "tire wedding" at the end of the production line. This requires substantial space for logistics handling and multiple stages of intermediate storage for the foam. Numerous additional manual or semi-automatic steps are required for logistics, cutting, adding adhesives and inserting the foam into the tire. And finally, for each tire produced, the appropriate foam must be provided "just-in-sequence". As a result, the manufacturing costs of a tire increase by up to 25% and it is often impossible to integrate the technology into existing tire plants. In addition, there are significant volumes of waste generated from the off cuts of the polyurethane foam pieces.

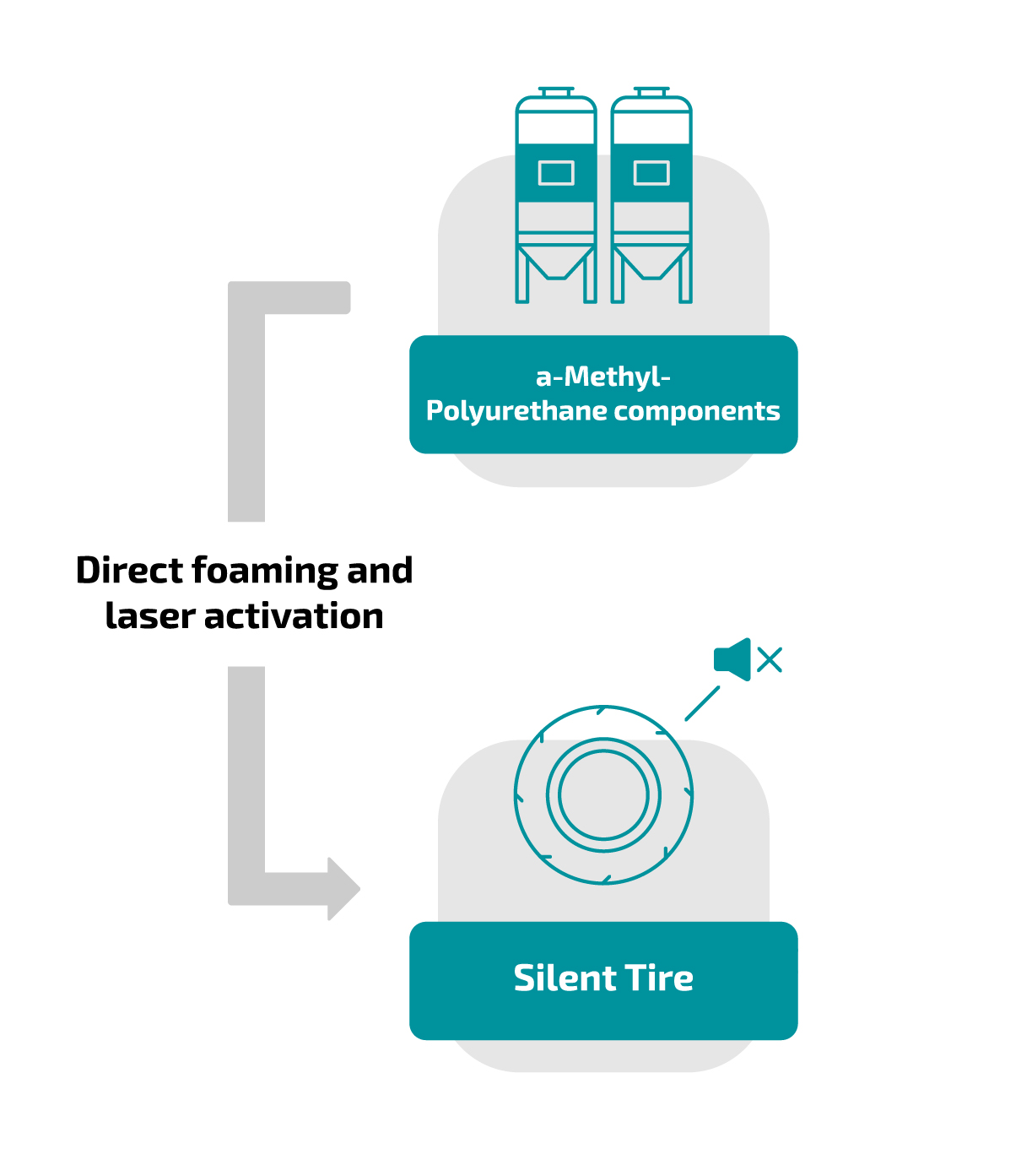

Silent Tires Reimagined: Direct Foaming with Subsequent Laser Activation

In the innovative LASER-FIT process, a tailor-made acoustic foam is produced directly inside the tire from liquid starting materials. Many of the disadvantages of the conventional process can be avoided. This direct foam process, which has long been established in other industries and applications, is made possible by the patented foam activation using a laser after the foam has been applied. In the activation process a powerful laser system removes part of the air-impermeable foam skin, that any foam system forms during generation and that prevents from noise absorption.

Simply Silent Tires – Direct Foaming with Significant Advantages

This LASER-FIT (short for “Laser foam-in-tire) method not only eliminates the just-in-sequence complexity, time-consuming logistics and manual process steps. It also gives the tire manufacturer greater freedom in adapting geometry and volume of the foam to the tire type. It significantly reduces footprint, CAPEX and inventories. Moreover, it minimizes waste generation and carbon footprint, and in many cases, it is the only sensible way to introduce Foam-in Tire technology in brownfield plants.

- Improve foam performance

- Increase flexibility

- Reduce inventory

- Reduce complexity and increase up-time

- Turnkey solution

- Reduce production footprint and logistics area

- Reduce waste and carbon footprint

- Become Brownfield ready

A Strong Team: Silent Tire Solution from Henkel and 4JET.

We build fascinating laser-equipment. However, chemistry and a secure international supply-chain for foam precursors are not our business. That is why we have partnered with Henkel, the world leader for technical adhesives and PU foams in the automotive industry. Henkels’ Loctite® LASER-FIT α-Methyl-PU foam and 4JET’s LASER-FIT Line are co-developed systems, tailor made to suit the mutual requirements for the best possible Silent Tire solution. And that is why we have no doubts that we will be able to serve the international tire industry with a consistent and reliable quality for Simply Silent Tires!

Curious? Let’s Clear It Up

Silent Tires are car tires with acoustic foam inside that reduce so-called tire cavity noise — a resonance sound inside the cabin. Especially in electric vehicles (EVs), where engine sounds are absent, this noise becomes more prominent. Silent Tires improve driving comfort, perceived quality, and contribute to environmental noise reduction.

The tire cavity generates disturbing resonances at certain frequencies. These negatively affect driving comfort. The effect is particularly noticeable in quiet electric vehicles. Current solutions require labor-intensive manual integration of PU foam pieces, resulting in high logistics, space, and cost requirements as well as production waste.

The disturbing noise is triggered by interactions between the tire and the road surface. Its volume depends on these two factors as well as the vehicle speed. It is dampened differently depending on the vehicle type due to the transmission properties of the vehicle and the encapsulation of the driver's cabin. The resonance frequency results from the length of the standing air column in the tire and can be estimated as the quotient of the speed of sound and the average of the tire circumference and the circumference of the rim seat:

λ = 340 m/s / (UR - UF) *; UR: tire circumference, UF: rim circumference.

It is also dependent on tire pressure and temperature.

The LASER-FIT process involves directly foaming liquid polyurethane (PU) inside the tire. After the foam is applied, a powerful laser system selectively opens the foam skin to activate its acoustic properties. This innovative method eliminates complex logistics, reduces production costs, and minimizes waste, making it an efficient solution for integrating foam-in-tire technology in both new and existing tire plants.

The LASER-FIT process offers several advantages. It eliminates complex logistics and reduces production costs by directly foaming liquid polyurethane (PU) inside the tire. The process also minimizes waste and carbon footprint, making it a sustainable solution. Additionally, it provides greater design flexibility in terms of foam shape and volume and can be easily integrated into existing tire plants.

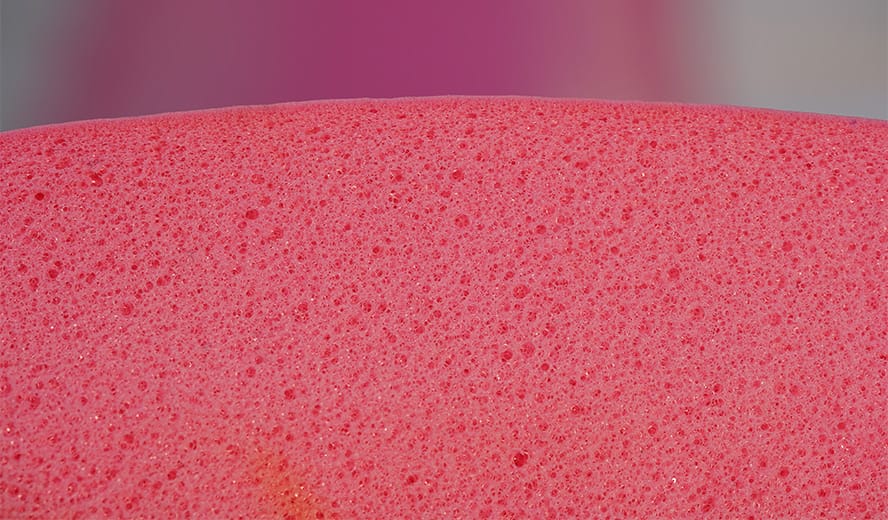

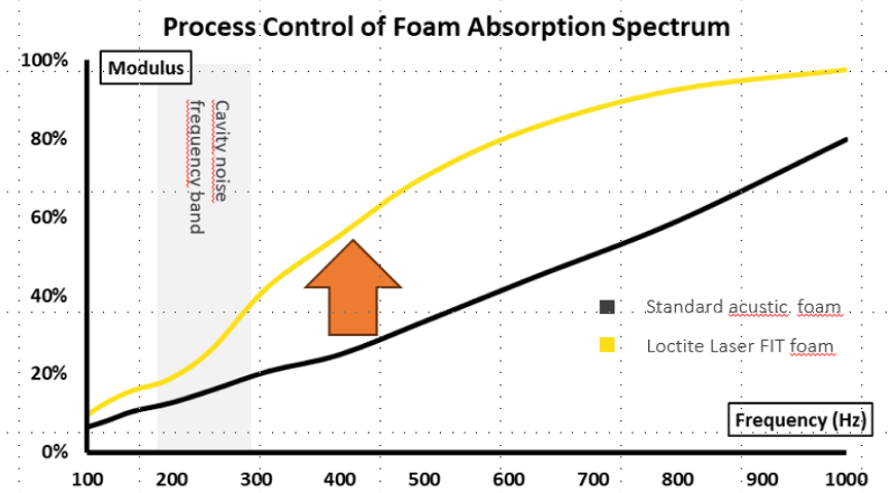

Loctite® LASER-FIT is a newly developed α-methyl functionalized acoustic foam (α-MPU Foam) especially designed for silent tires. It features an extremely large open cell inner surface and optimized loss modulus to increase sound absorption properties. Its low density minimally increases rotating masses in the tire. The foam has a high affinity towards rubber surfaces and excellent adhesion without special adhesive. It also has reduced hygroscopic behavior, meaning it has low affinity to capture moisture in high-humidity environments. Additionally, it includes integrated flame protection for extreme tire usage and speedy laser activation. The foam's optimized viscosity allows for the desired foam geometry, and its fast reaction speed supports 4JET’s high throughput LASER-FIT Line.

Yes, the LASER-FIT process is ideally suited for Brownfield retrofitting. Due to the high throughput of the process, production space is reduced, as well as storage and logistics space. There is no need for storage near the production facilities.

The LASER-FIT process uses the specially customized Loctite® LASER-FIT α-Methyl-PU foam tailored for the silent tire application. Especially in the area of tire cavity resonance frequency, it absorbs noise better than conventional acoustic foam. Furthermore, it allows for the optimal foam geometry and volume for each tire type, balancing tire performance and tire comfort as well as allowing for economy or premium foam. The process benefits from Henkel's expertise in technical adhesives and PU foams, ensuring reliable and consistent quality.

Yes, the new groundbreaking technology is protected by several utility models and pending international patent applications from both Henkel and 4JET. Key representatives include: DE202023107514U1; DE202024104283U1; DE202024001792U1; PCT/EP2024/087281.

Source: Impedence tube measurements according to ISO 10534-2

Measuring body diameter 2 inch, averaged over several material samples. The curves are averaged over 1/12 octave.

All leading tire manufacturers market the Silent Tire technology under different brand names. Michelin uses Michelin Acoustic Technology; Falken has developed Silent Core Technology; Toyo offers Silent Technology; Continental adds the ContiSilent designation; Pirelli refers to the technology as PNCS (Pirelli Noise Cancelling System); and Bridgestone calls it B-Silent. Other names for this technology include Quiet Tire Technology, Tire Soundproofing, Noise-reducing Tires, Tire Cavity Noise Reduction, and Acoustic Foam Technology. These are all variations of the same technology, which incorporates a sound-absorbing foam body within the tire.