Optics & Optical Components

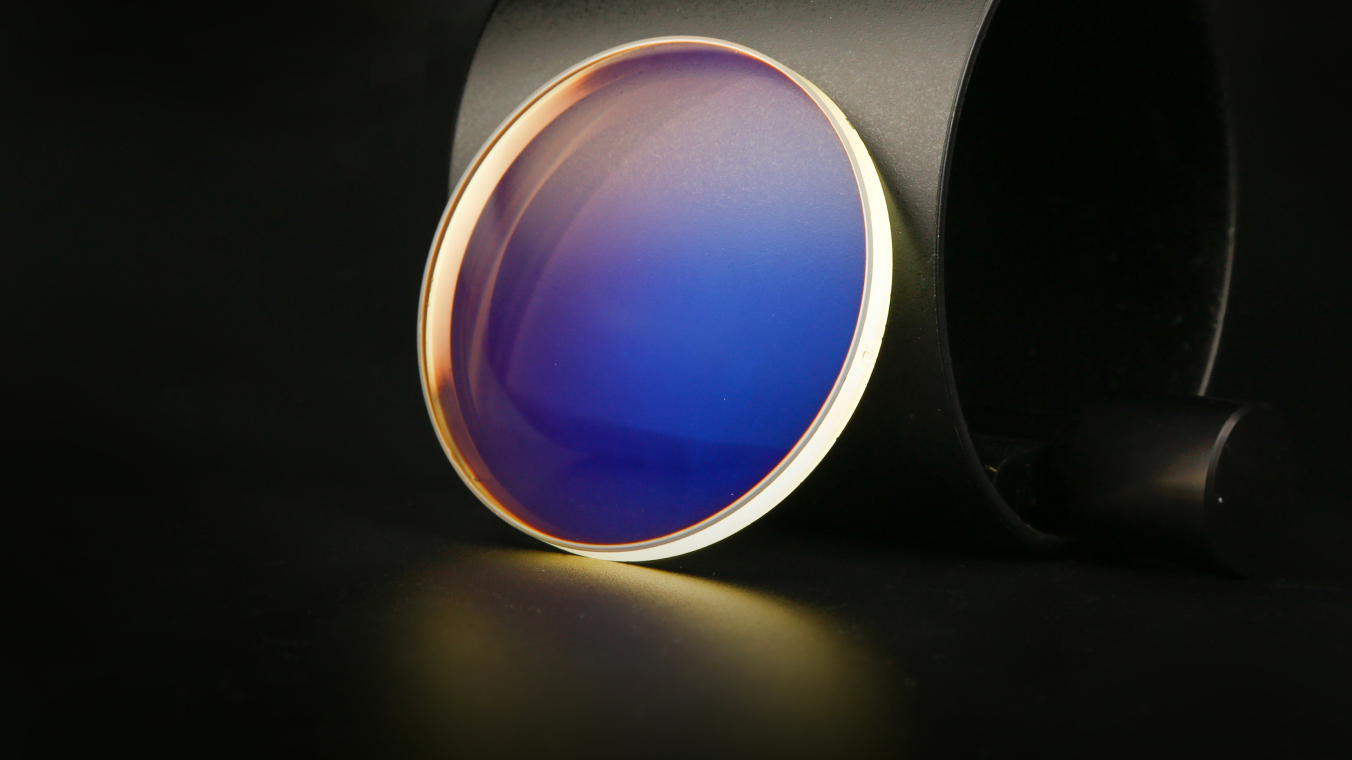

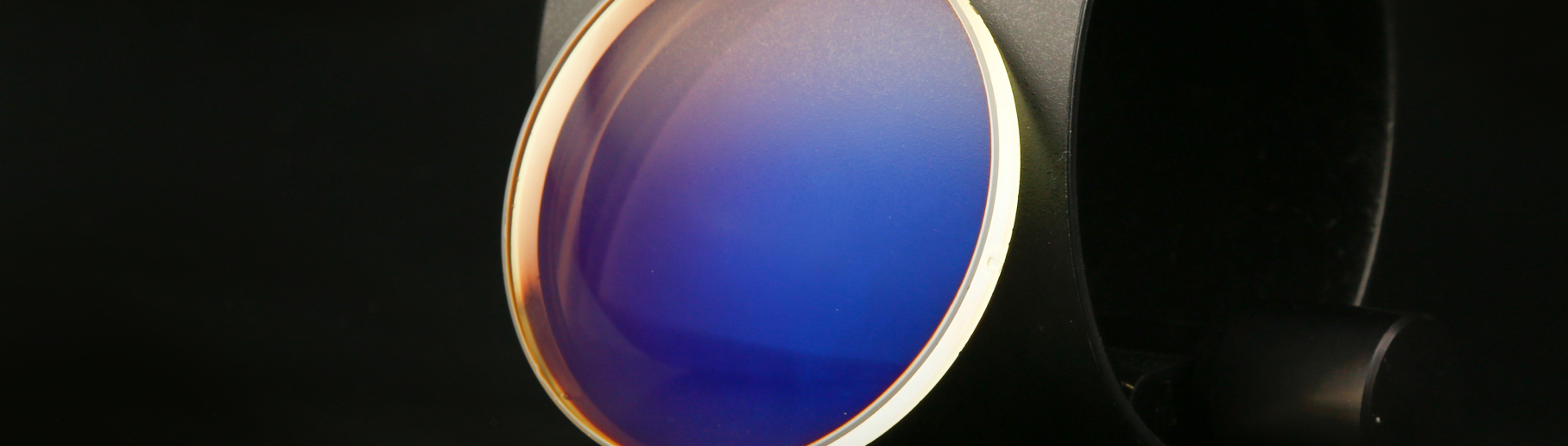

Laser Precision for Optical Glass and High-Performance Optical Components

We offer high-end laser systems for cutting, drilling, and microstructuring of optical glass – enabling ultra-clean, contactless processing of lenses, waveguides, prisms, filters, and other advanced optical elements.

Empowering Innovation in Optical Glass Manufacturing

Modern optics demand extreme precision. Whether in imaging systems, AR/VR devices, metrology, or photonics, the performance of optical components depends on flawless geometries, crack-free surfaces, and contamination-free fabrication.

Our laser micromachining platforms deliver sub-micron precision for cutting, drilling, surface texturing, and selective coating removal of optical materials – without mechanical contact, tool wear, or thermal distortion. Our systems support complex 2D and 3D geometries and are compatible with ultra-thin, chemically strengthened, and coated glasses.

From prototyping to volume production, we enable manufacturers to meet the highest standards for clarity, functionality, and reliability in optical components.

Key Technical Features for Optics & Optical Components Processing:

Precision Cutting of Optical Glass Components

Applications:

- Contour cutting of wafers, blanks, lenses, filters, or optical carriers

- Suitable for flat, curved, or coated substrates including fused silica and BK7

4JET Technology Fit:

- Bessel beam laser cutting for stress-free edges and exceptional optical quality

4JET Solution:

- Optical-grade cutting performance with no need for post-polishing – ideal for imaging and beam-shaping optics

4JET Platforms:

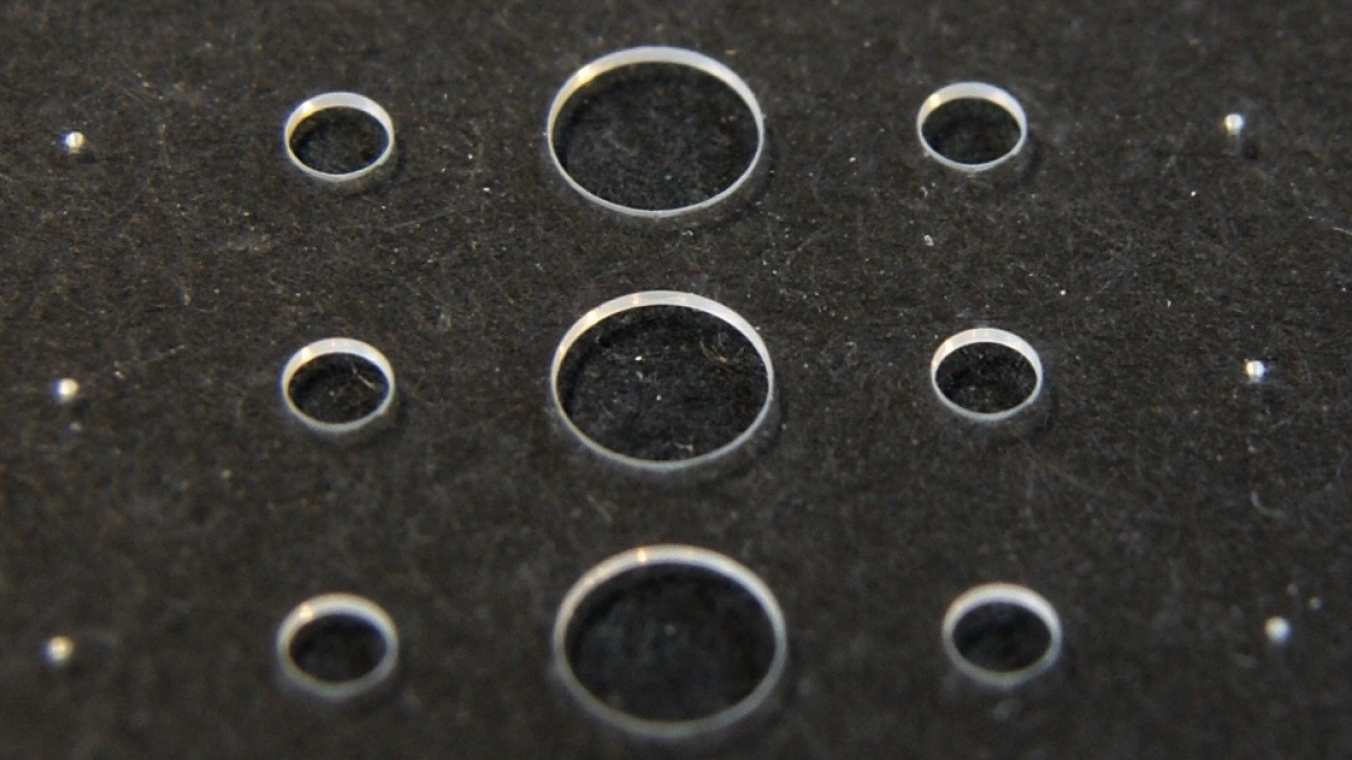

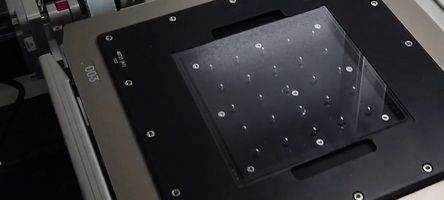

Drilling & Feature Machining in Optical Elements

Applications:

- Apertures, holes, notches, and mounting features in precision optics

- Used in optical assemblies, photonic circuits, and optical sensors

4JET Technology Fit:

- USP laser micromachining with micron precision and low thermal impact

4JET Solution:

- Clean, high repeatability and dimensional control – suitable for brittle or coated materials

4JET Platforms:

Surface Structuring and Texturing

Applications:

- Light-guiding, anti-reflective, and diffractive microstructures

- Functional surfaces for bonding, coupling, or light shaping

- Used in AR combiners, optical sensors, or lens arrays

4JET Technology Fit:

- Grayscale and binary laser structuring with design-driven patterning

4JET Solution:

- Tunable microstructures with precise control of depth, geometry, and optical function

Coating Ablation & Edge Deletion

Applications:

- Selective removal of AR, dielectric, or metallic coatings

- Creation of bonding zones, electrical contacts, or optical windows

4JET Technology Fit:

- Laser ablation of thin films without substrate heating or damage

4JET Solution:

- Clean, precise, and maskless coating removal – preserving optical performance and surface integrity

Prototype & Custom Optics Manufacturing

Applications:

- R&D and rapid iteration of optics for AR/VR, biomedical, and imaging

- Custom-shaped, custom-coated components for niche or early-stage applications

4JET Technology Fit:

- Flexible toolpath generation and quick-change setups

4JET Solution:

- Modular systems for high-mix, low-volume manufacturing – ideal for optical R&D labs and pilot lines

4JET Platforms:

Why 4JET?

High-precision laser platforms tailored to optical glass applications

Trusted by optics manufacturers across photonics, metrology, and consumer te

Non-contact, ultra-clean processing – ideal for optical-grade results

Automation-ready and cleanroom-compatible for seamless integration

Let’s Talk Optics

Discover how our laser solutions can help you achieve precision, flexibility, and scalability in optical component production.

Enabling Capabilities Across All Optics Applications

Optical manufacturing demands precision, cleanliness, and flexibility to meet the highest standards in lenses, waveguides, prisms, and advanced photonic devices. Our laser platforms empower optics producers to deliver flawless components with scalable automation and smart software.

Core4 Software Platform Global Services & Support Automation Integration

Core4 Software Platform

Powered by Core4, our laser systems integrate seamless automation, machine vision, and process control tailored for optical manufacturing.

- Modular, scalable software with intuitive UI/UX designed for ease of use

- AI-powered vision for defect detection and precision alignment

- Robust audit trails and data logging for quality assurance

- Fast deployment using pre-tested building blocks, backed by a dedicated 20+ developer team

Automation Integration

Flexible automation solutions for high-mix, low- to high-volume optics manufacturing:

- Robotic loading/unloading and conveyor interfacing for fragile optics

- Cleanroom-compatible systems with controlled environmental parameters

- Integration with metrology and assembly lines for streamlined production

Let’s Talk Optics

Discover how our laser solutions can help you achieve precision, flexibility, and scalability in optical component production.