PEARL 80G – Precision Laser System for Large Glass Substrates

The PEARL 80G sets new standards for high-precision laser cutting of glass.

Designed for large-format substrates, the system relies on ultra-fast laser pulses and our exclusive nanoPerforation (nP).

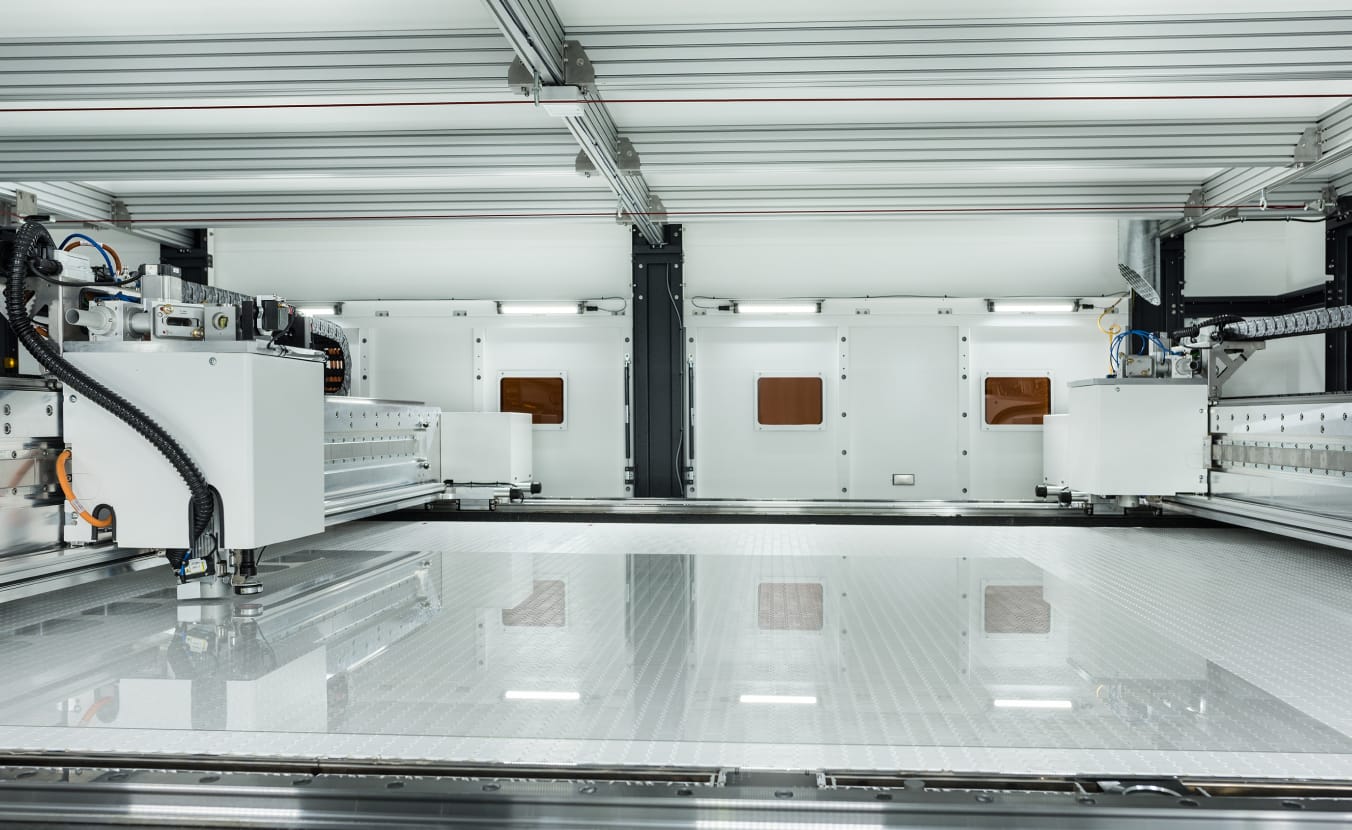

Built on an ultra-stable granite gantry with linear motor axes and combined with a patented material handling system, it guarantees top machining quality. Developed for production environments, the PEARL 80G can be used as a stand-alone solution or fully integrated into a production line.

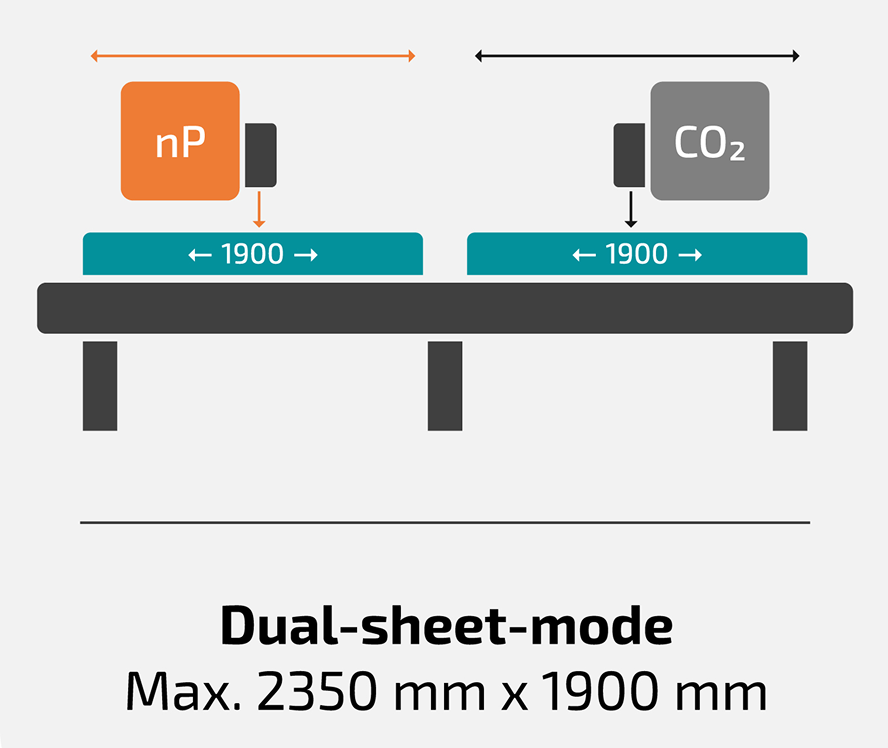

Its unique design enables parallel processing of two glass sheets on separate worktables, significantly increasing throughput. In “Dual-Sheet Mode,” the maximum substrate size is 2,350 mm × 1,900 mm.

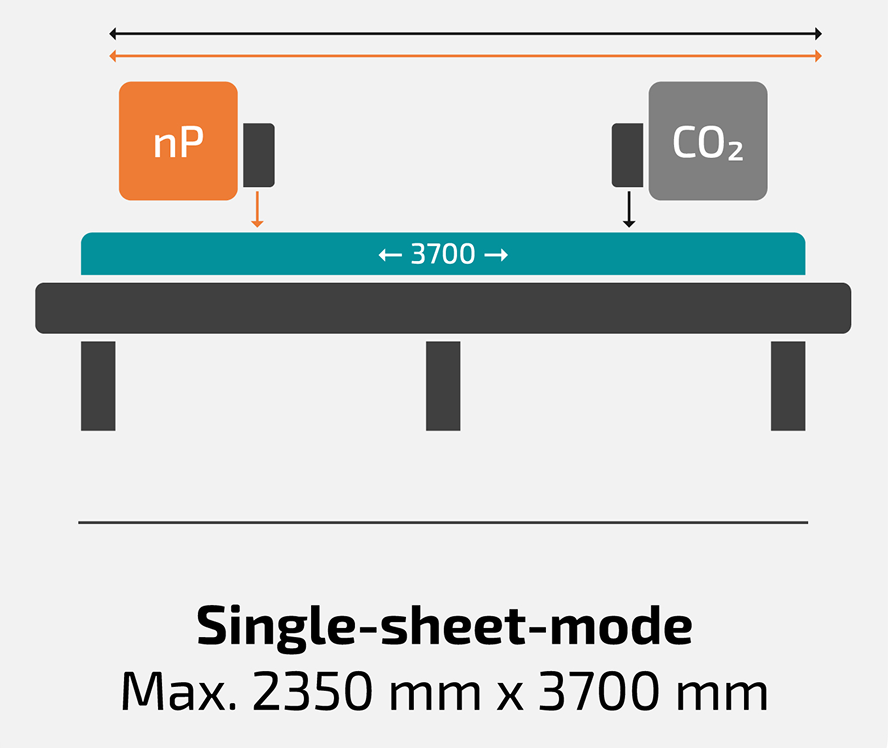

For oversized glass sheets, the “Single-Sheet Mode” processes substrates sequentially, with a maximum size of 2,350 mm × 3,700 mm.

Applications for the PEARL 80G

Photovoltaics & Thin-Film Technologies

Designed for specialized photovoltaic applications, the PEARL 80G delivers ultra-precise processing of large glass substrates. Its contact-free laser cutting minimizes thermal and mechanical stress – ideal for sensitive, multilayer functional coatings.

Consumer Electronics & Semiconductor / MEMS

From cover glass for tablets and smart displays to camera modules, sensor covers, and substrates for advanced packaging, MEMS, and glass-core applications – the PEARL 80G is the perfect choice for large-format glass processing. Its precise, non-contact laser technology creates complex geometries with exceptional edge quality.

Automotive & Aerospace

Ideal for large glass and glass-ceramic components in automotive and aerospace applications such as touch interfaces, head-up displays, sensor covers, mirrors, and optical systems. Using nanoPerforation and thermal separation, the PEARL 80G achieves precise freeform and internal cuts – contact-free, low-stress, and with superior edge quality.

Flat Glass & Large-Scale Architectural Applications

Ideal for large glass and glass-ceramic components in automotive and aerospace applications such as touch interfaces, head-up displays, sensor covers, mirrors, and optical systems. Using nanoPerforation and thermal separation, the PEARL 80G achieves precise freeform and internal cuts – contact-free, low-stress, and with superior edge quality.

Optical Components

Perfect for large optical substrates made of glass, quartz, or glass-ceramic. Applications include optical windows, filter holders, lens blanks, beam splitters, and other precision components. nanoPerforation and thermal separation allow for complex geometries – contact-free, low-stress, and with the highest optical quality.

PEARL 80G Highlights

Technical Details:

| Category | Feature | Specification |

|---|---|---|

| System size & weight | Dimensions (W×D×H) | 16,000 mm x 4,150 mm x 2,250 mm |

| Weight | ~18,000 kg | |

Axes & movement | Max. processing area | Single sheet: 2,350 mm × 3,700 mm Dual sheet: 2,350 mm x 1,900 mm |

| Feed speed | Up to 90 m/min | |

| Acceleration | Up to 10 m/s | |

| Dimensional accuracy | < 2,5 µm + 7,5 × 10⁻⁵ × L | |

| Repeatability | ≤ 2 µm | |

Software & operation | HMI | Touchscreen-based user interface |

| CAD import | DXF, simple job configuration | |

| Vision system | cVision with fiducial and edge detection | |

| Height sensor | Precise processing along the height profile of the substrate | |

| Beam stabilization | Immediately detect and counteract beam drifts | |

| MES connection | SECS/GEM (optional) |