Laser drilling is a highly precise, contact-free process used to create holes, internal contours, and micro structured features in glass and other materials.

The Future of Glass Processing

Laser drilling is a key process in modern glass processing. It is increasingly replacing mechanical drilling techniques – not only because of its superior drilling quality, but also because of its process reliability and flexibility. Whether ultra-thin glass, hardened substrates or complex internal contours: technologies such as controlled laser ablation can be used to reliably meet the most demanding requirements. Laser glass drilling offers clear advantages for industries such as microelectronics, medical technology, display manufacturing, and architectural glass – from minimal particle formation and high edge quality to maximum material utilization.

We offer machines for laser drilling with two specialized laser technologies:

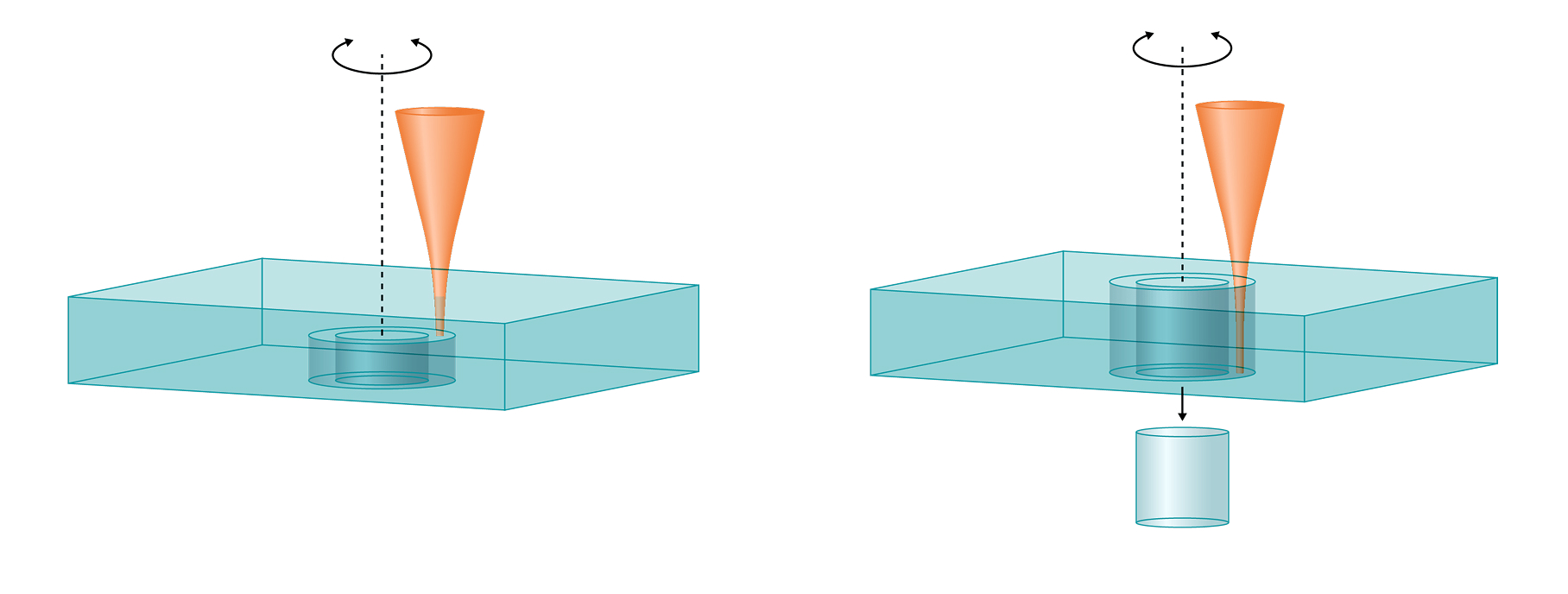

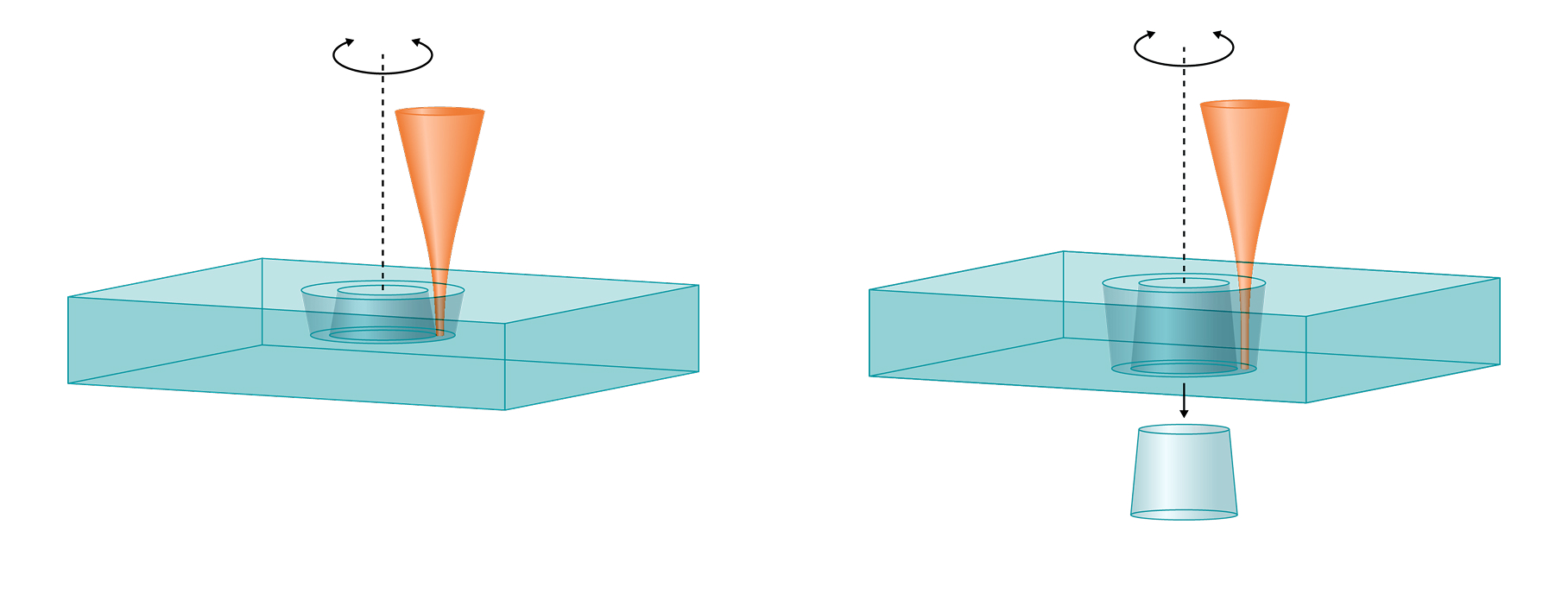

Ablation from bottom to top

A well-established laser processing technique leverages the high optical transparency of glass to the laser beam for precise and efficient material interaction. This allows the laser focus to be placed on the back of the glass and moved layer by layer toward the front surface. This method is particularly suitable for robust drilling at high process speeds and is ideal for many industrial applications. The use of a nanosecond laser makes the drilling process comparatively fast.

Process parameters:

- 1.5 s – 2.5 s @ EXG© 0.5 mm Ø1.0 mm

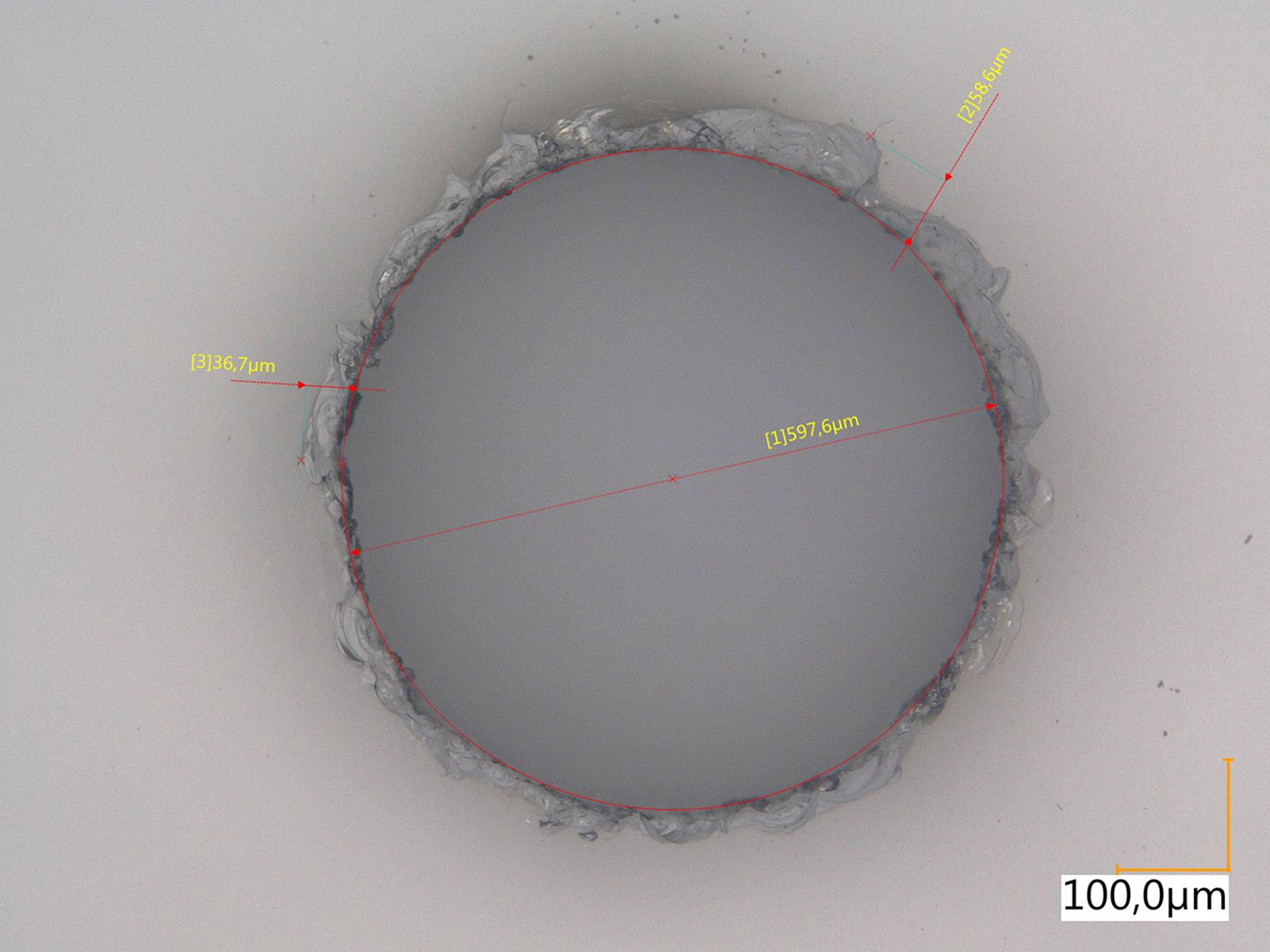

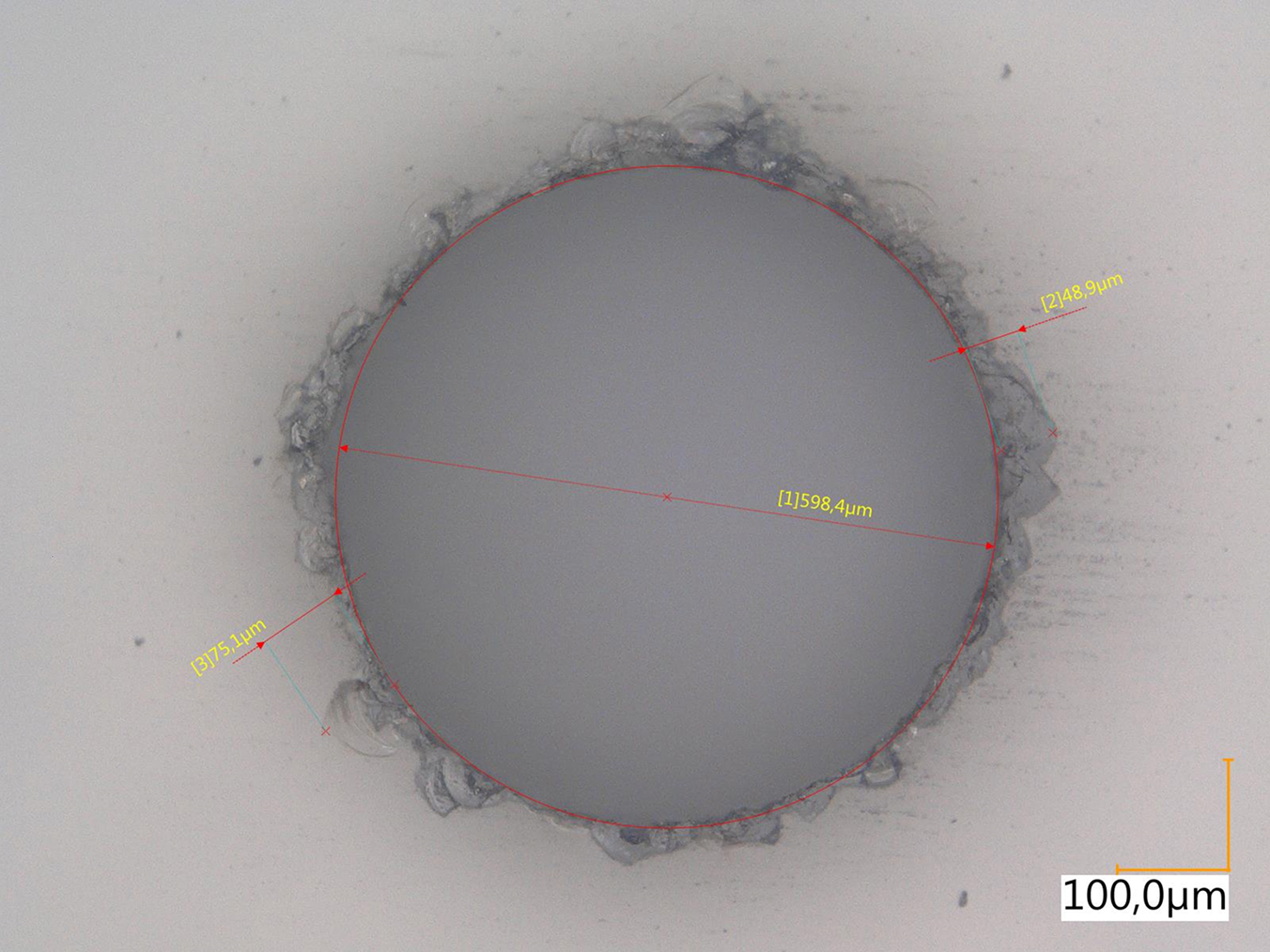

- Chipping < 150 µm

- Minimum taper up to 0°

- Aspect ratio up to 1:4 (diameter to borehole depth) depending on the product

Ablation from top to bottom

Picosecond or femtosecond lasers can be used for high-precision applications. In this case, the material’s transparency cannot be utilized, as nonlinear absorption dominates. The laser focus is therefore guided from top to bottom. However, the ultra-short pulse durations enable particularly clean, low-stress, and low-particle drilling – ideal for delicate glass and applications with the highest quality requirements.

Process parameters:

- 3.5 s – 4 s @ EXG© 0.5 mm Ø1.0 mm

- Chipping < 50 µm

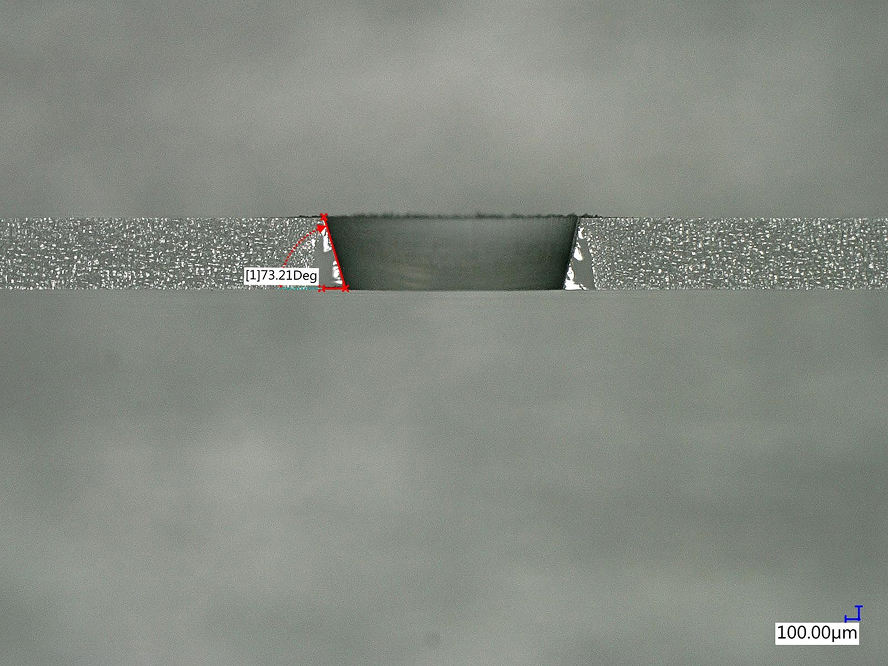

- Minimum taper < 15°

- Aspect ratio: Depends on taper and glass thickness (typically 1:1)

For special applications, we are currently working on integrating femtosecond ablation into our portfolio. This technology promises even greater precision, lower heat impact, and new possibilities for processing the most demanding types of glass. If you have any questions, please do not hesitate to contact our sales team.

Unlike traditional mechanical drilling, the laser process allows for:

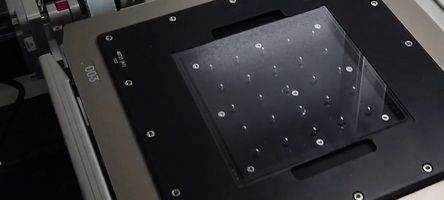

Efficient extraction is a key element of laser technology:

We rely on specially developed dual-sided extraction systems. This ensures reliable removal of drilling dust, significantly improving both process cleanliness and the quality of the holes – while also extending the service life of system components.

Laser drilling enables dry, stress-free, and low-particle drilling, even with glass thicknesses of less than 0.1 mm – ideal for applications in display technology, sensor technology, and medical technology.

Advantages of laser glass drilling over mechanical processes

| Criterion | Laser glass drilling | Mechanical drilling |

|---|---|---|

| Precision | Very high, ideal for micro drilling | Limited by tool geometry |

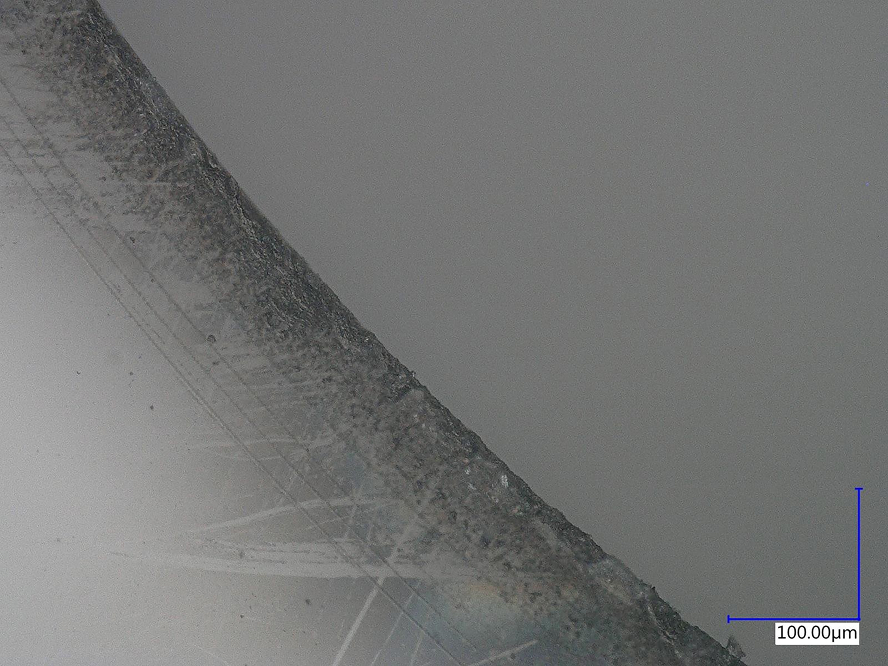

| Edge quality | Smooth drill walls, minimal chipping | Coarse, often requires reworking |

| Microcrack formation | Very low | Frequent microcracks and breakouts |

| Particle formation and auxiliary media | Low particle formation, controllable by extraction. No auxiliary media (water, etc.) required | High particle formation, flushing/cooling fluid required |

| Material utilization | High utilization due to precise geometries and close nesting through contactless machining | Higher loss due to breakage and tolerances |

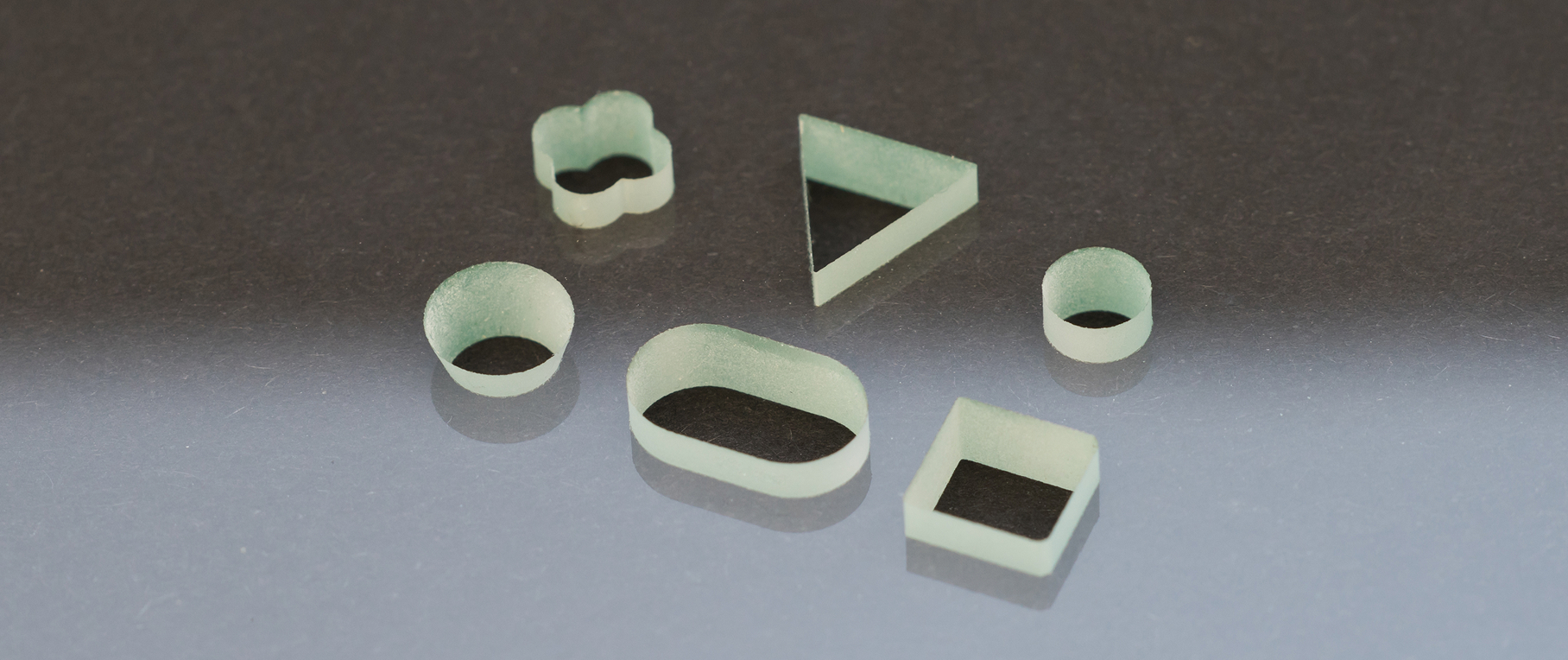

| Geometric flexibility | Funnel and hourglass shapes possible, limited by process physics | Usually only simple shapes can be realized |

| Machining of thin glass | Optimal, even < 100 µm possible | Risk of breakage with thin glass |

| Maintenance | Low, no tool wear | High, regular tool changes |

Applications for Laser Glass Drilling

Laser drilling is used in numerous industries where maximum precision, cleanliness, and minimal material stress are required:

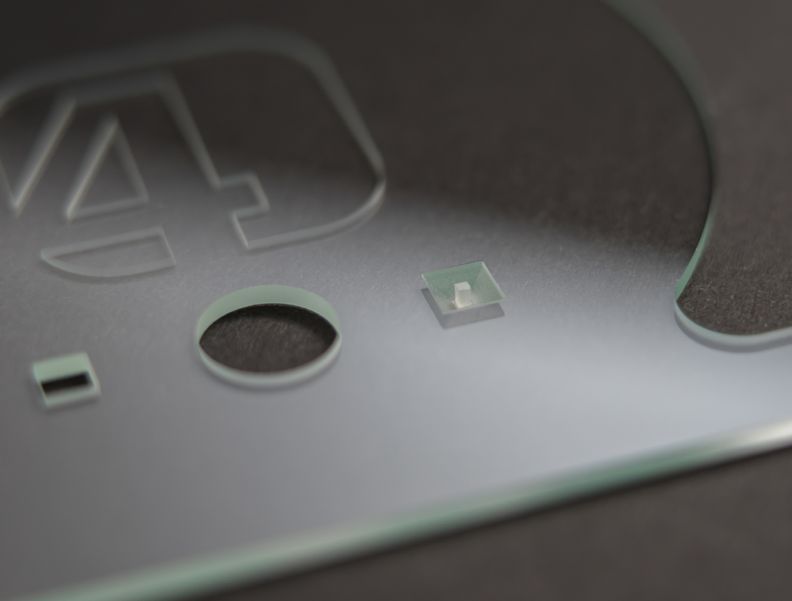

Micro-drilling for loudspeakers, cameras, or sensors – with smooth drill walls and minimal chipping.

Drilling for functional elements or light modules – even in coated glass.

Interior cutouts for sensors, HUDs, or control elements – with high edge quality and process reliability.

Micro-holes for through-hole vias, microfluidics, or analysis chips – low-particle and precise.

Drilling in diagnostic systems, lab-on-a-chip applications, or microfluidic components.

Structured drilling in thin glass for solar modules or coating substrates.

Precise internal contours in lenses, filters, or encoder discs – without thermal stress.

FAQ: Laser Glass Drilling with 4JET Technology

Soda lime, borosilicate, and thin glass are suitable. Chemically hardened glass can also be processed, depending on the degree of hardness.

Typical hole sizes range from 50 µm to several millimeters. Free forms and elongated openings are also possible. It is important that the aspect ratio is maintained.

Thanks to the contactless process, glass thicknesses below 100 µm can be processed without any problems.

Yes – Our laser drilling process is used in series production. The technology impresses with its very high reproducibility and extremely low process variations, which enables consistently high quality across large quantities and has already proven itself in various industrial applications.

Very low crack formation, edge roughness below Ra 2.5 µm – ideal for optical and functional applications.

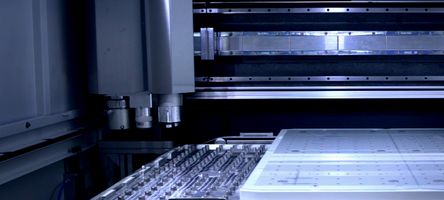

Yes – We offer industrial laser machines with integrated drilling process, as a standalone solution or for line integration.

Our laser systems only require electricity, water (PCW), and compressed air (CDA) – no special operating media or complex infrastructure measures are required. In addition, the systems are designed so that they can be operated by trained personnel without special laser knowledge – ideal for use in an industrial environment.

Yes – through our MicroFab JobShop, we offer sampling and small-batch production for process validation.

The costs depend on the type of glass, thickness, geometry, and degree of automation. We would be happy to provide you with a customized quote or perform an ROI calculation.