Technology & IP

Pushing the Limits

At 4JET, we combine deep domain knowledge with relentless innovation to develop cutting-edge solutions in laser processing, automation, software, and system integration. With a highly skilled international team, world-class infrastructure, and a strong IP portfolio, we bridge the gap between research and high-volume industrial production. Our technology enables customers worldwide to increase productivity, reduce costs, and shape a more sustainable future.

Relentless Innovation

Staying ahead in technology is not just a pillar of our strategy, but also our passion. Finding new ways is part of our DNA and our team drives forward what can be done in laser surface processing, glass machining, software and automation.

Multi-Disciplinary and Multi-Cultural

Our team of thinkers and tinkerers is made up of people from 25 different nations and a broad range of scientific and engineering backgrounds. Closely observing the research community and understanding the needs of industry customers, we are ideally positioned at the interface of “lab to fab”.

Worldclass Infrastructure

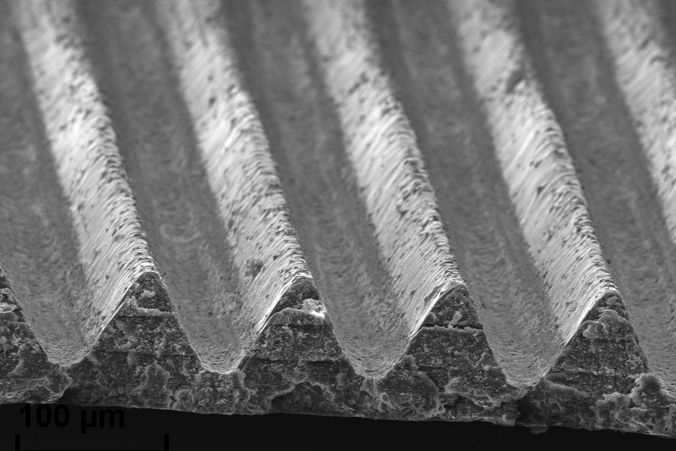

2,000m² of laboratories, dozens of test laser systems and full-scale machines, top notch metrology like scanning electron and laser scanning microscopy, 3D printing and more – our infrastructure to perform development work is unmatched in our peer group.

Intellectual Property

As we continuously invest a double-digit share of our revenue in new technological capabilities, we have created a significant stack of intellectual property rights. Over 130 patent families with some 450 patents protect these investments. We actively manage this portfolio to assure freedom-to-operate to our customers. Where needed, we aggressively defend our rights against infringements.

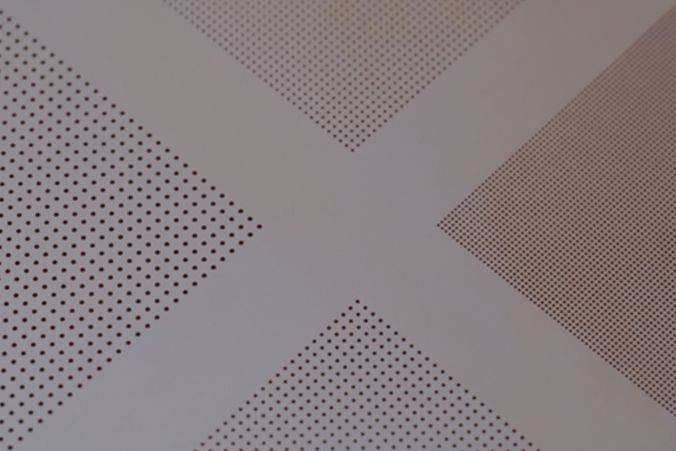

Specifically, we hold significant international patent portfolios in laser tire processing, laser glass cutting, laser surface functionalization by DLIP, as well as for several other applications and end products.

What Sets us Apart

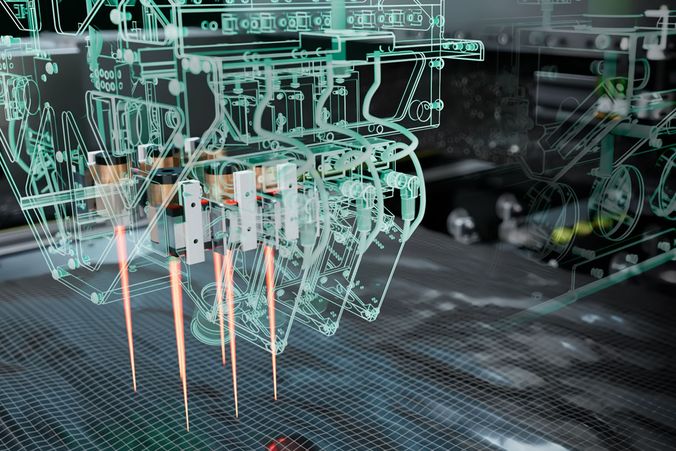

Our capability is unique in many ways: Starting from the core laser processes such as Bessel beam processing of brittle materials, or interference patterning of organic coatings to advanced beam delivery solutions such as multiplexing 36 individual laser beams. All the way to ultra-precise high throughput automation solutions that require micron accuracy, repeatability and dynamics in the m/s range.

It is not the one “secret formula” but the integration of process, automation and software.

From Lab to Fab

Our Unique Capabilities to Scale Laser Technology from R&D to Industrial Manufacturing

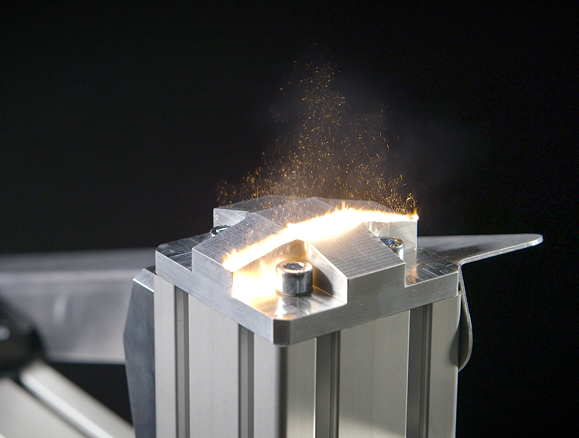

Laser Process Technologies

- Surface cleaning and modification by pulsed laser ablation

- Free form high precision cutting of glass and brittle materials

- Laser interference patterning for surface functionalization

- "Superblack" high contrast markings

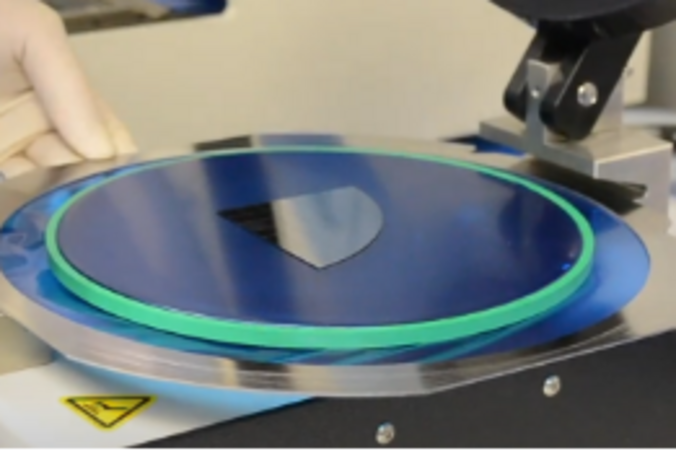

- Scribe and break dicing of wafers

Advanced Beam Delivery

- High throughput with multi-beam processes (up to 36 laser beams with individual auto-focus and path tracking)

- Processing large substrates (e.g. 2x3 meters) in µm precision

- Remote scanning (ultralarge scanfield size of 1m)

- µm precision at m/s speed

Machine Vision

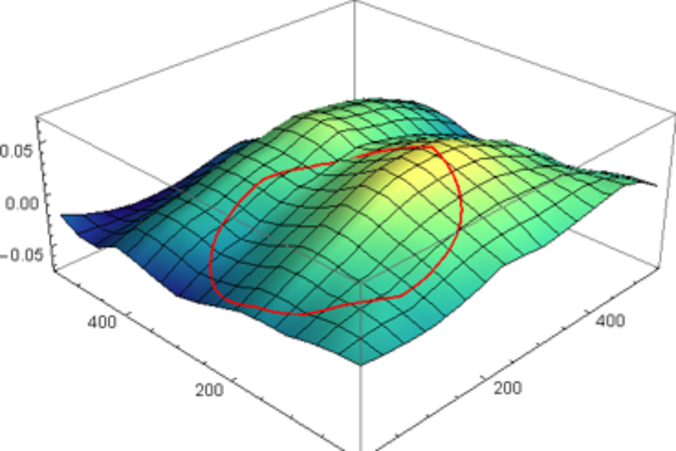

- Sheet of light scanning of surfaces

- Fast topography mapping

- Fiducial alignment

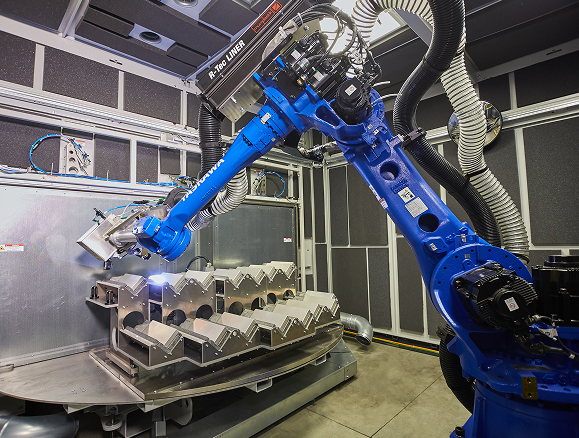

Precision Automation

We combine laser process solutions with automation and parts handling. For our glass and semicon products this includes for example:

- Scratch free glass and wafer handling

- Cassette and box loading

- SCARA and linear robots

- Tape frames and expanders

- Waste handling and crushers

Our customers benefit from turnkey solutions, seamless line integration and maximum yield in high volume manufacturing operations.