Meeting the Tire Uniformity Challenge with Laser-Based Solutions

Every detail counts – because in tire production, minimal uniformity deviations can lead to major performance and safety issues. Tires that fail to meet strict uniformity standards can cause vibrations, noise, and uneven wear, reducing the overall driving comfort and increasing rejection rates from automotive manufacturers. These uniformity deviations result from slight variations in materials or manufacturing steps, gradually adding up to compromise the overall quality of the final product.

Recognizing the industry's need for a precise and reliable correction method, we introduce a laser-based solution that overcomes these uniformity issues – fast, contactless, and flawlessly repeatable.

Why Tire Uniformity Matters

Even with advanced manufacturing, tolerances in the various manufacturing steps may accumulate and impact a tire´s uniformity negatively. Meaning, a certain percentage of a tire plants output consists of tires that do not meet the expected quality standards.

These imperfections lead to:

- Vibrations and noise

- Uneven wear

- Reduced driving comfort

- Increased rejection rates from OEM customers

- Labelling to prevent grey imports

Uniformity testing identifies these issues and differentiates between:

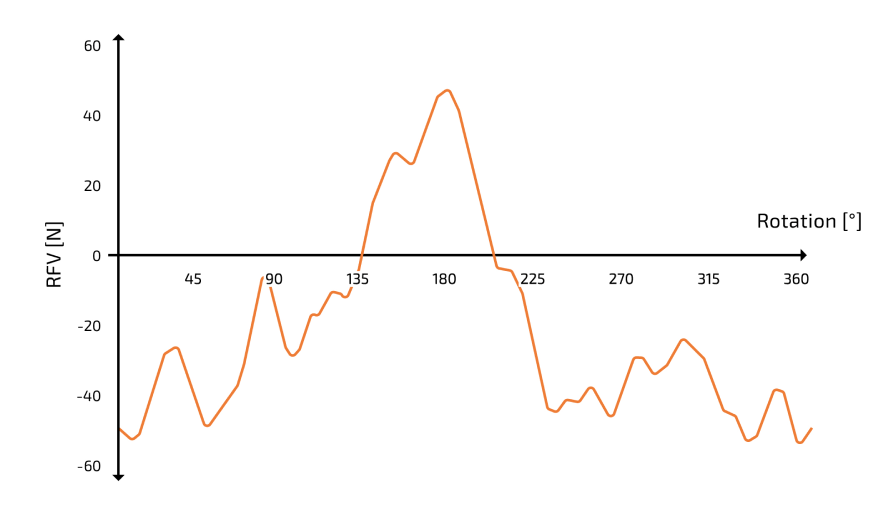

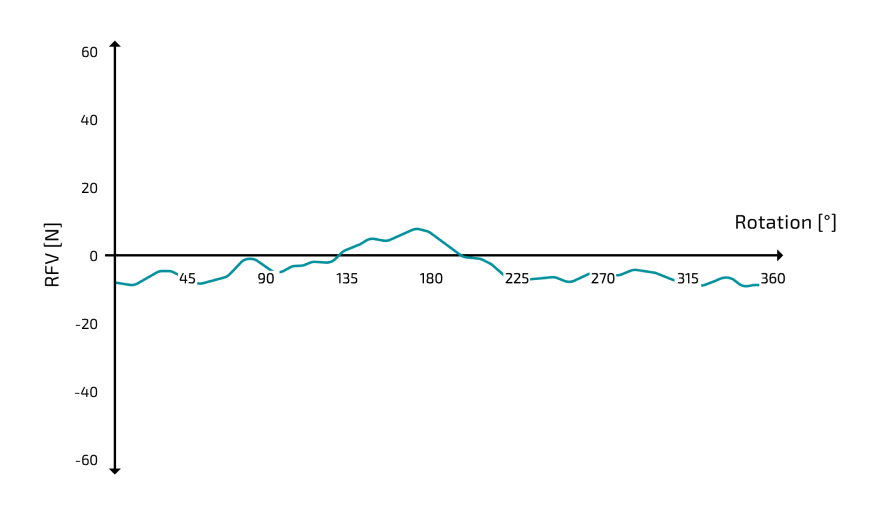

- Radial force variation: Occurs when a tire is not perfectly round, creating periodic vertical forces during rolling.

- Lateral force variations: Occurs when a tire is not perfectly symmetrical. This leads to pulling to one side or uneven force transmission to the suspension. The result is higher rolling resistance, unstable steering, and irregular tire wear.

- Conicity: Arises when stiffness or height differs between the inner and outer sides of the tire. Instead of rolling straight, the tire drifts to one side – much like a cone spinning across a flat surface.

Precise Laser Ablation Significantly Reduces Radial Force Variation

Laser ablation selectively removes very small amounts of material at the tire beads, the area where many uniformity issues originate, invisibly, precise, and permanently

Key Benefits of Laser Tire Uniformity Correction

The Traditional Correction Method: Mechanical Grinding

Traditionally, non-uniformity in tires is corrected through mechanical grinding on the outside of the tire. This method has been established in the tire industry for decades, but it comes with several disadvantages:

- Material loss: Rubber is permanently removed – the tire is “used” before it hits the road.

- Tool wear: Grinding heads wear out and require frequent replacement.

- Visual degradation: The tire no longer looks new after grinding.

- Temporary effect: The root cause of the non-uniformity (e.g., at the bead) is not addressed – issues may reappear after a few hundred miles.

Deliver perfection with every tire. Explore laser uniformity correction now.

Contact us to learn how laser-based tire uniformity correction can optimize your production and quality KPIs.

FAQ: Laser-based tire uniformity correction

Tire uniformity refers to the consistency of force distribution as a tire rolls. Variations in radial or lateral forces can cause vibrations, noise, and uneven wear.

Laser correction uses contactless ablation to remove microns of material at the tire bead seat, targeting the root cause of non-uniformity. Unlike grinding, it leaves a perfect finish, avoids dust and eliminates the need for consumables.

Material is removed with micron-level accuracy, exclusively at the bead area. The laser leaves a smooth, unmarked surface – the changes are completely invisible to the eye. Unlike grinding, the tire retains its new appearance. Our technology ensures a premium finish that meets even the most demanding OEM standards.

Laser correction is contact-free – no grinding wheels, no dust, no filters. It eliminates tool wear and reduces maintenance to a minimum.