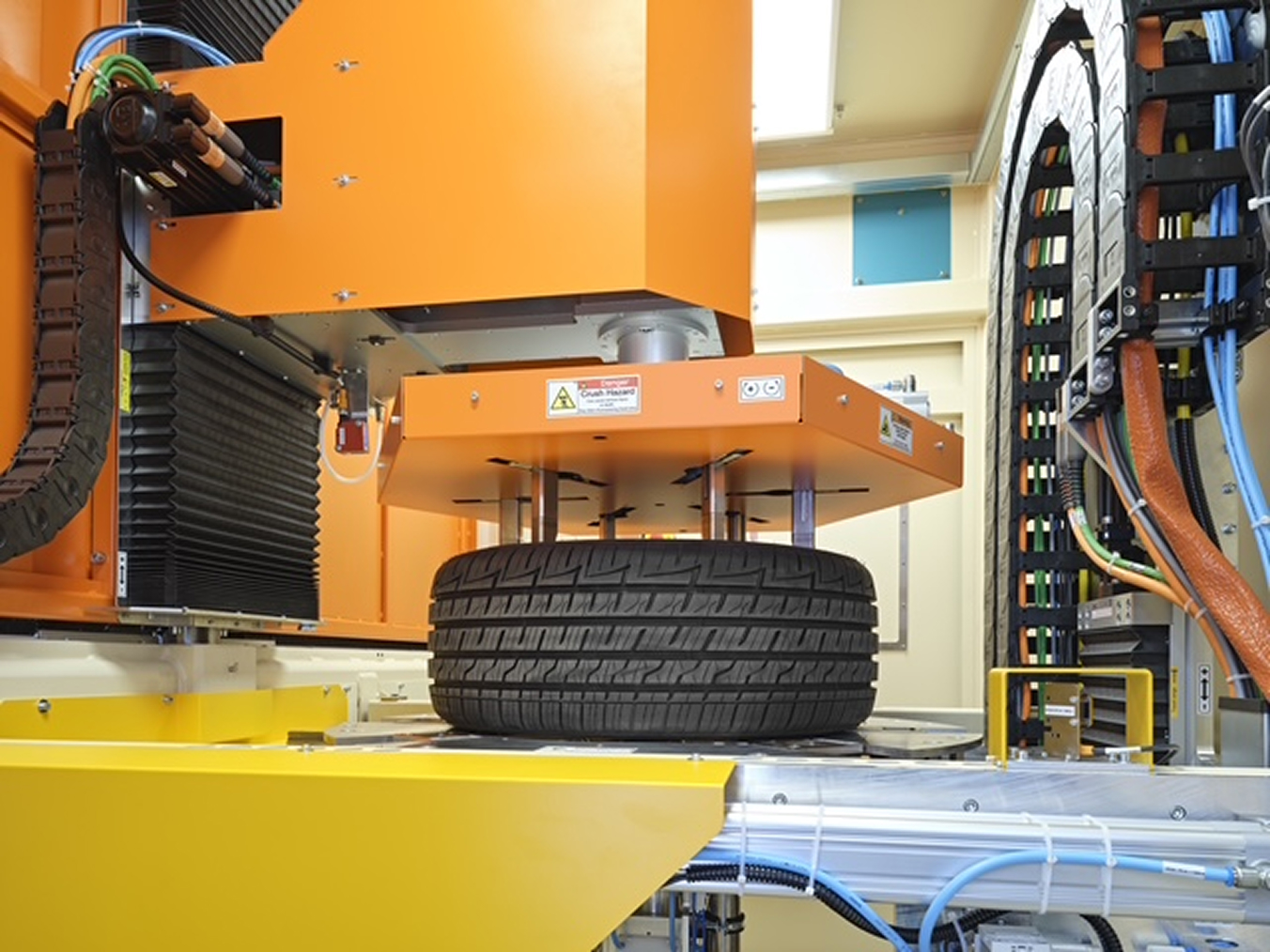

TCS – Tire Inner Liner Laser Cleaning System

Perfect Adhesion by 4JET Laser Cleaning

Laser cleaning allows to remove release agents, oils and contaminants from the inside inner liner surface of a tire. By using laser ablation, such unwanted coatings can be efficiently removed without damaging the underlying tire.

The resulting surface is perfectly clean and prepared for adhesive bonding processes.

Enabling Seal-, Silent or RFID Fitted Tires

Tire makers are increasingly adding functionality to their tires after the curing process. Key applications include

- Self-sealing materials to heal punctures

- Noise cancelling foams to reduce emissions to the inside of a vehicle

- Sensors to monitor tire conditions

The TCS systems allow to clean tire insides in a fully automatic inline process.

Compact, Dry, Repeatable Laser Cleaning

Many leading tire makers are using 4JET laser inner liner cleaning systems for their obvious benefits compared to other solutions

- Repeatability - our laser systems provide the consistency needed for a safety critical bond

- Selective processing - only desired areas are cleaned

- Compact footprint - lasers require app. 25% of the footprint of an industrial wet washing machine

- Dry process - no need to collect and recycle large amounts of contaminated water

- Inline capability - TCS systems can be line integrated unlike offline batch cleaning and drying

Smart Laser Machines

Our TCS cleaning systems comprise years of experience in building integrated laser process solutions in modern tire manufacturing. Some of the unqiue features of our machines include

- Auto-teach capability - new tire models are ready for production in the shortest possible time

- All digital - recipes can be created for specific tires and compound mixes

- Advanced debris management - our evacuation system removes the sticky byproducts efficiently

- Condition monitoring - our optical path will know if there is contamination on the laser window and issue a warning in time to provide for preventive maintenance

The perfect match – TCS, T-Mark and customized application solutions out of one hand

Customizing a regular tire into an added value seal-, silent- or RFID-equipped tire downstream - after the curing room - allows to dramatically reduce working capital and create a more responsive supply to market demands. By combining TCS tire cleaning systems with our automated T-Mark tire marking system, tire makers can add product or feature specific logos, symbols and other identifiers on the sidewall.

We are also offering customized solutions for material application and glueing solutions form selected partners.

4JET TCS Technology International Property Rights

As the market leader for laser-based machine tools, we regularly spend a double-digit percentage of our turnover on further development. To protect these investments, we maintain a portfolio of international industrial property rights for our systems, processes used and/or products manufactured with our processes. The most important of these intellectual property rights are listed below:

DE102013220066, EP32818101, DE2020191009471, US2018/00456111, CN201680059094.7A2, EP16864125.6A1, 2, JP2016566832A2, US15/775,6482, KR1020187009804A2

1 property right pending (status May 2020)

24JET holds a license