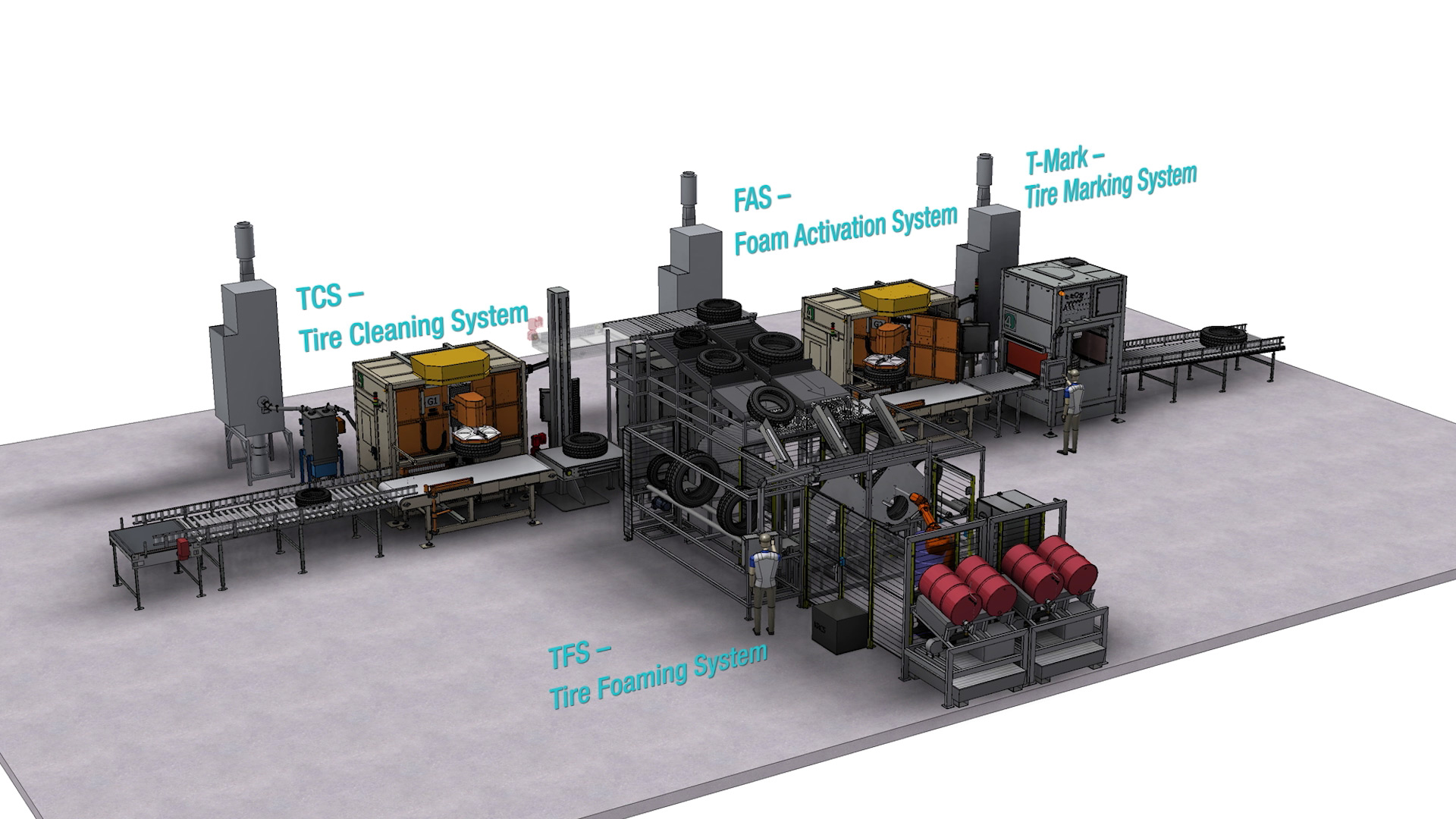

The LASER-FIT Line

The Simple Way to Silent Tires

In the innovative LASER-FIT process, a tailor-made acoustic foam is produced from liquid starting materials directly in the tire. Just-in-sequence complexity, time-consuming logistics and manual process steps are eliminated, and foam geometry as well as foam volume can be adapted per tire to the quality level desired.

Direct foaming of acoustic tire foam, long been established in many other applications, is made possible by the patented foam activation process using a laser after the foam has been applied.

Key Benefits Compared to Conventional Foam-in-Tire Solutions

TCS – Tire Cleaning System

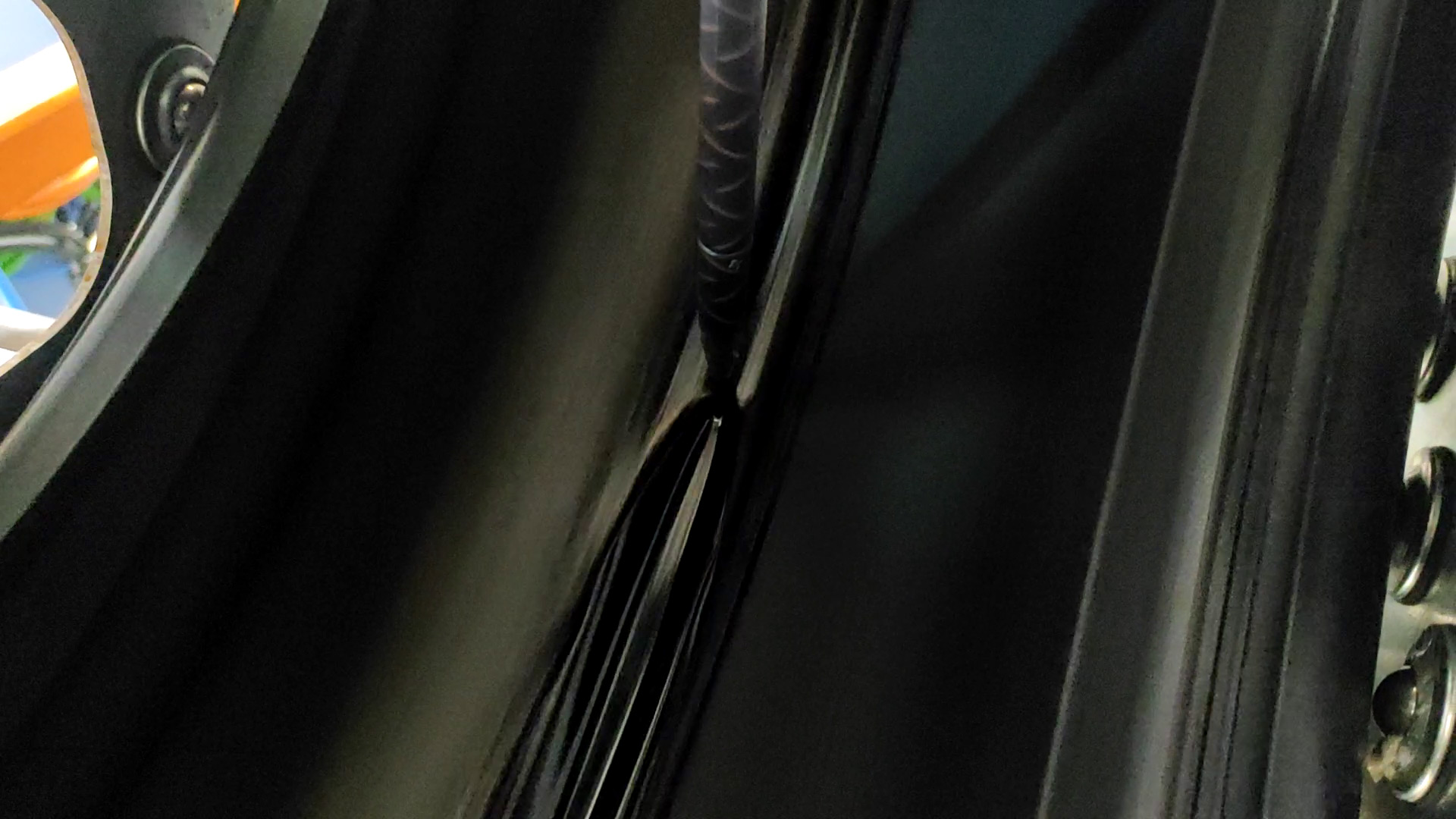

The LASER-FIT process starts with a thorough cleaning of the tire to guarantee optimal bonding of the foam. In our market leading TCS System release agents, oils and contaminants from the inside inner-liner surface of a tire are removed by laser ablation without damaging the tire and in a most environmentally friendly way.

Cleaning parameters and cleaned areas are adjusted to the desired foam geometry and bonding strength and are optimized for high throughput.

TFS – Tire Foaming System

The Tire Foaming System is based on the market leading Promera 2K sealant applicator system. The system comprises two alternating application stations, allowing for very short foam reaction times and hence highest throughput. An integrated tire buffer minimizes standstill times and hence, unnecessary loss of precursor material. After foam application tires are again buffered on a tire rotator to assure a smooth foam surface.

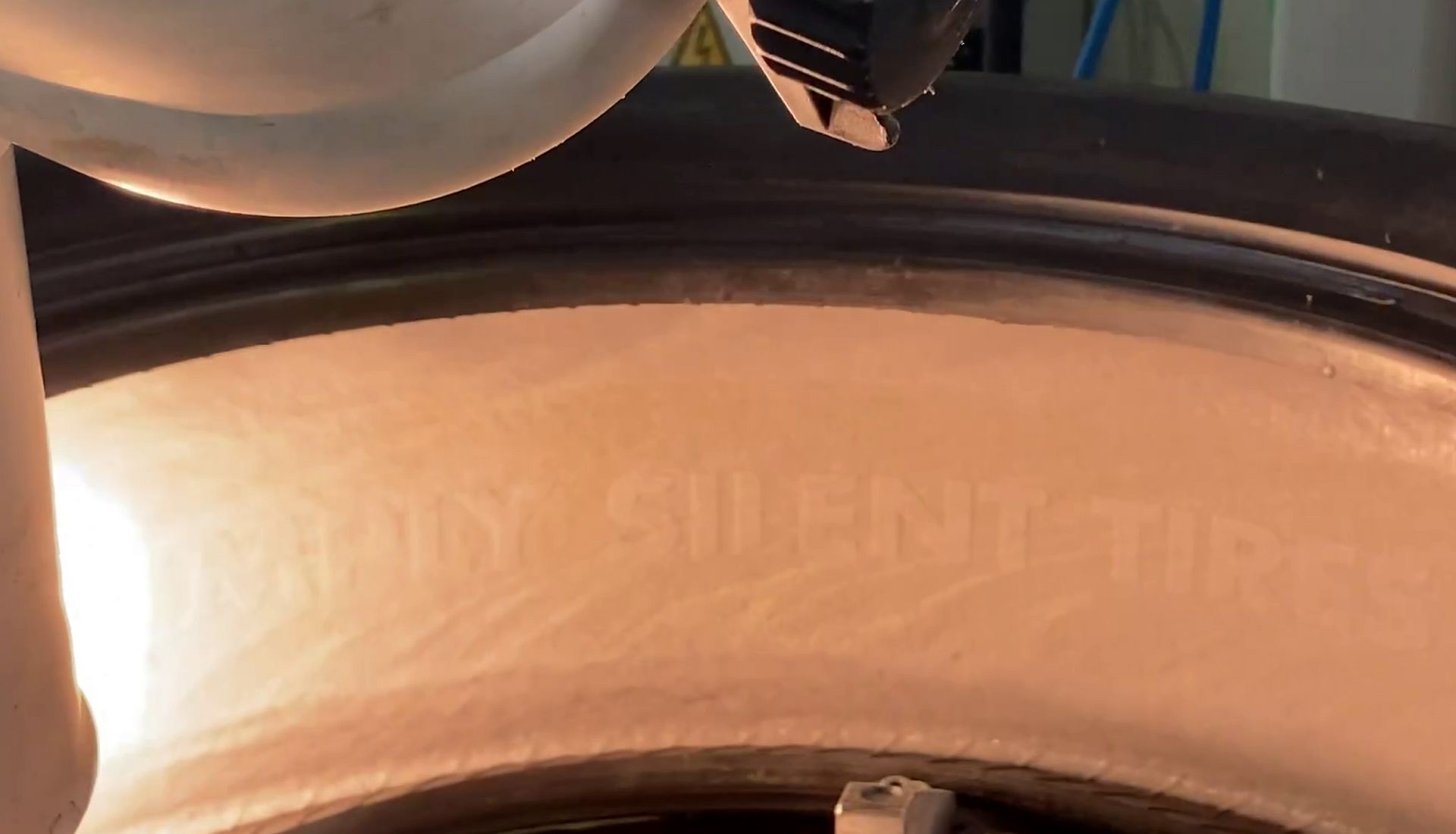

FAS – Foam Activation System

Similar to a yeast dough, any foamed in place foam forms an air-impermeable skin on the surface during production. In the Foam Activation System, this sound reflecting skin is removed in an efficient laser process and the special sound absorption capabilities of Loctite® LASER-FIT foam are "activated".

The FAS is based on the robust TCS System with modified laser settings.

T-Mark – Tire Marking System

Many tire makers choose to base their Silent Tires on regular tire models, thereby avoiding an unnecessary increase in inventory. Laser engraving of the foamed tires with a special silent tire brand feature allows to recognize these high value tires. Our T-Mark is the system of choice for this final finish of the tire. With more than 150 installations worldwide it provides a very fast and reliable way to mark your tire with different engravings on the dedicated location on the tire sidewall.