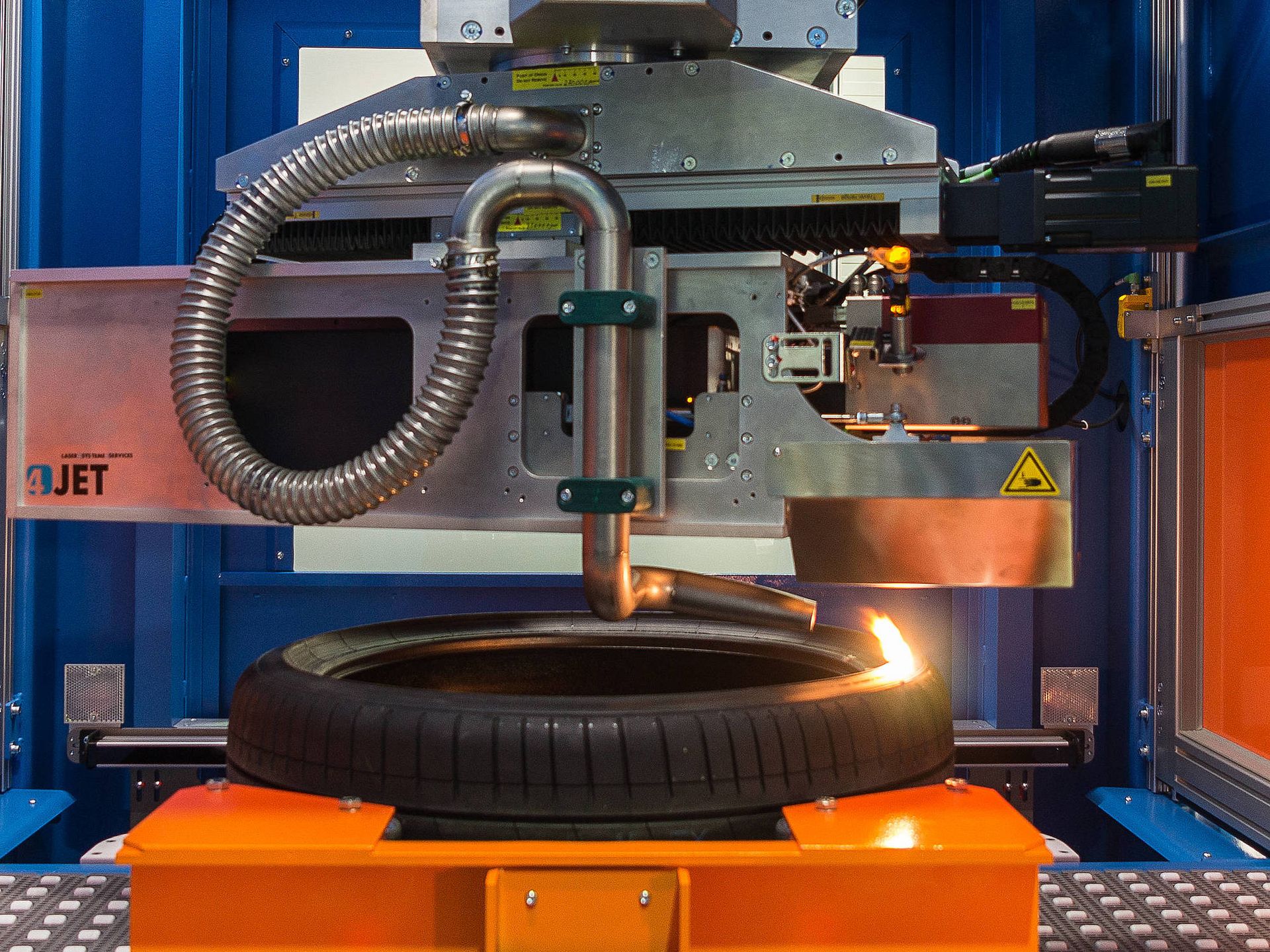

T-Mark – Fully Automated Laser Tire Marking System

Industry Standard in Tire Marking

With around 200 systems installed worldwide, our fully automated T-Mark tire laser marking system and the handheld T-Mark Compact system are in daily operation at leading tire manufacturing facilities across Europe, the Americas, and Asia. These systems are trusted by virtually all major tire makers and have already laser-marked more than one billion tires globally.

Highly flexible, T-Mark systems can engrave bitmaps, DXF graphics, alphanumeric characters, and 2D matrix codes onto tire sidewalls – covering diameters from small 14-inch passenger tires up to large 25-inch super-single truck tires. The systems support random-order processing and stand out with short cycle times, robust engineering, integrated quality control, and an intuitive interface for both operation and maintenance. These features have established T-Mark as the industry benchmark for laser-based tire marking.

Laser Marking

Built for continuous operation – reliable even under high production loads.

Adapts automatically to different tire types and recipes.

Class 1 laser enclosure protects operators and meets top safety standards.

Best-in-Class Performance

Cycle time depends on the size and complexity of the engraving as well as the validation steps selected before and after marking. With one-sided engraving, the system can usually mark over one million tires per year.

The contact-free laser process ensures gentle handling of the tire surface and keeps wear-part costs to a minimum. When maintenance cycles are adhered to or operated under a 4JET maintenance contract, the system typically achieves over 95% uptime, requires minimal consumables (mainly aspiration filters and cleaning agents), and features low energy consumption.

The system is fully automated. With the optional auto-teach feature, even new tire models can be introduced without manual setup - eliminating operator involvement during teach-in. Daily operation is straightforward and requires minimal training. The T-Mark’s core system has a compact footprint of just 2 m x 2 m; the total system size (including e-cabinet, aspiration unit, flippers, and access area) is typically around 16 m², depending on the individual layout.

Safe, Flexible, and Proven Laser Marking

After automatic tire feed-in and recipe handover, the tire is positioned beneath the rotating laser processing head. The sidewall is scanned, and the laser head then precisely moves to the marking area as defined in the tire-specific recipe.

Based on this predefined recipe, the system automatically executes all required steps: pre-validation routines, one or more marking passes, post-validation procedures, and – if necessary – tire flipping. All relevant process data is logged and transferred to the customer's MES system after tire feed-out.

The laser process uses a sealed CO2 laser and is fully enclosed in a Class 1 laser-safe system, meaning it poses no laser hazard during operation and does not require additional safety measures for operators.

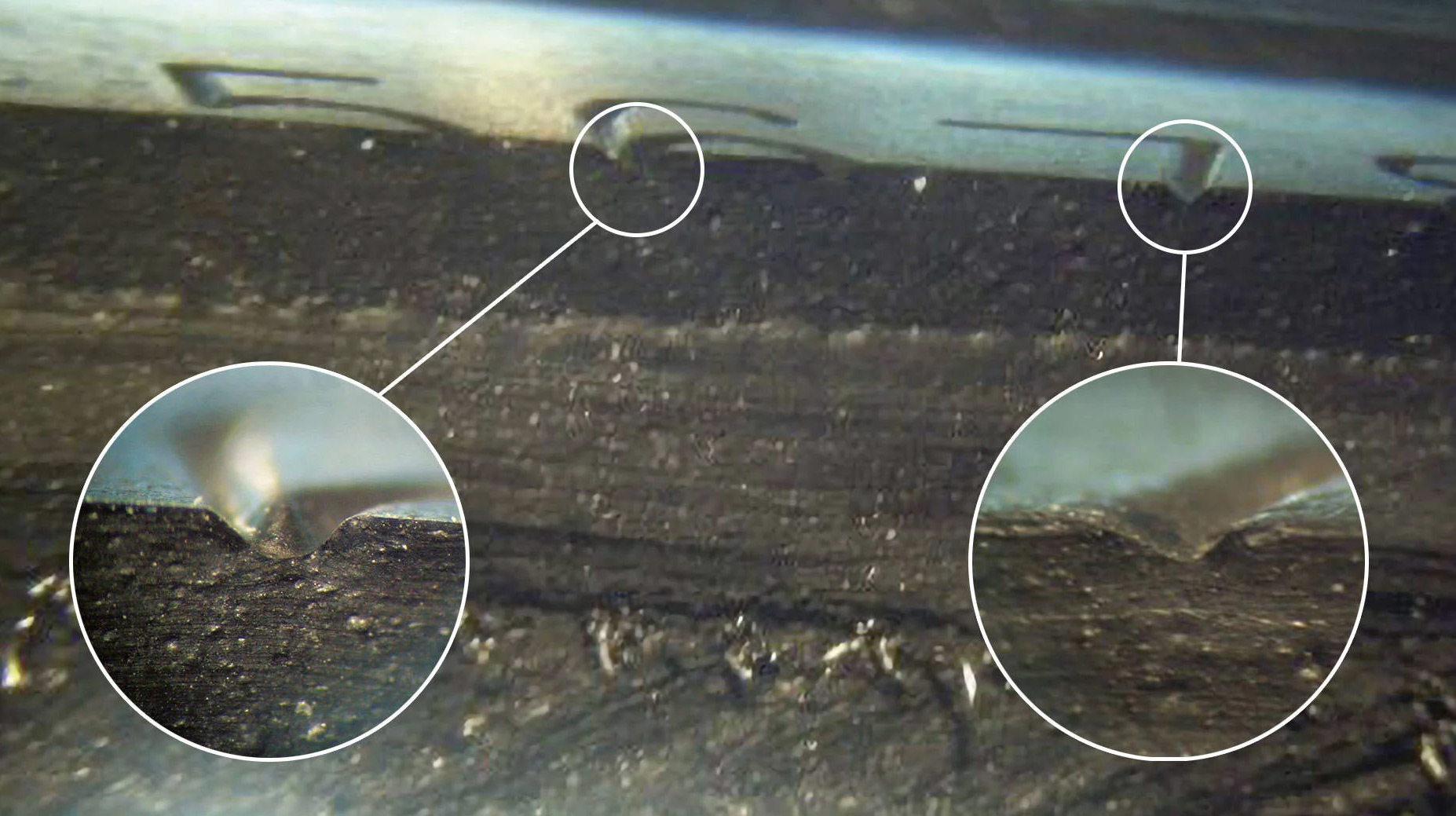

The marking is performed via laser ablation, which vaporizes the top layer of the rubber surface into a carbon-laden smoke, safely extracted by the integrated filtration unit. The laser energy is applied locally and only to the surface, ensuring high energy efficiency and preventing damage to deeper layers of the sidewall. In addition, the Gaussian-shaped laser beam creates smooth and rounded edges in the engraving, minimizing notch effects and mechanical stress on the tire structure.

Key Features

Our market-leading tire marking technology comes with a comprehensive set of advanced features designed to ensure consistent quality, high efficiency, and highly reliable operation. A state-of-the-art sensor system continuously monitors performance and detects deviations from the defined process.

An intuitive workflow system allows users to easily create new tire recipes and process sequences, offering maximum flexibility to adapt the system to various tire types or specific MES requirements such as engraving type, position, or validation step combinations.

Before marking, the system can evaluate multiple potential engraving positions to avoid damaging existing color marks like balance dots. Markings can be validated using model matching or optical character recognition (OCR). The engraving quality of 2D matrix codes can be improved using projection correction to compensate for the curvature or angle of the side wall.

Areas of Application

The ability to engrave all kinds of logos, characters, numbers, or 2D matrix codes gives the T-Mark system a broad range of applications.

The engraving of logos and legally required symbols helps reduce inventory complexity and streamline tire production.

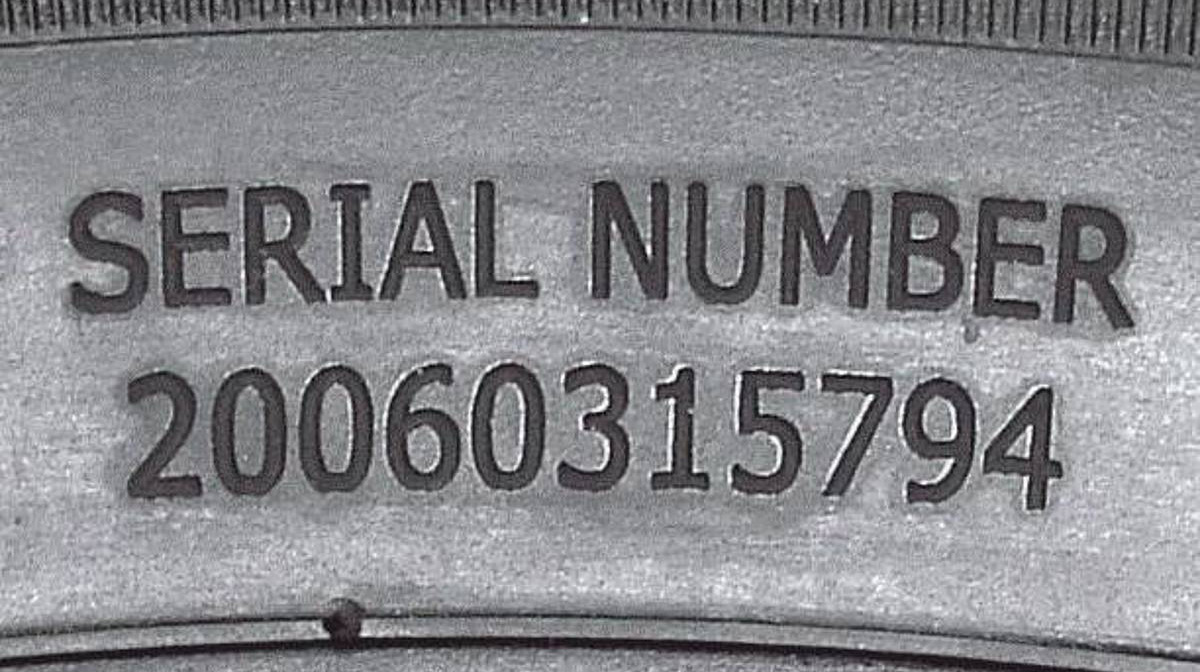

Fully automated laser marking of DOT date codes eliminates the need for manual slug changes in the curing press, offering significant economic and operational benefits.

The use of unique 2D matrix codes is essential to meet future regulatory, and market demands while staying competitive. These codes enable seamless traceability throughout the entire lifecycle of a tire - from manufacturer to retailer to end user to disposer. They also improve efficiency across key processes such as production, warehousing, vehicle assembly, and maintenance. In addition, the T-Mark system is fully Digital Product Passport (DPP) compliant, enabling the digitalization of tires to support future EU regulations and sustainability goals.

International Intellectual Property for our T-Mark Technology

As a global leader in laser-based production systems, we invest a significant share of our annual revenue into innovation and technology development. To protect these investments, we maintain a robust portfolio of international intellectual property rights covering our systems, processes, and the products manufactured using them. A list of the most relevant patents and trademarks is provided below:

EP2905125, EP2977934, EP3147114, EP3238928, US2006/0161381, EP32818101, DE202014010855, DE202014011007, DE202017103420, US2018/00456111, EP3284586, CN107743450, KR10-2017-70367681, EP32978161, DE2905125, FR2905125, GB2905125, CA29993751, EP34486681, CA30223411, DE602014036348, CN1100146801, DE3147114, FR3147114, GB3147114, DE 20 2020 104 479.6, WO 2018/224601 (DE)1, WO 2018/224601 (KR)1, US 2019/01350115011

1 property right pending (status August 2020)