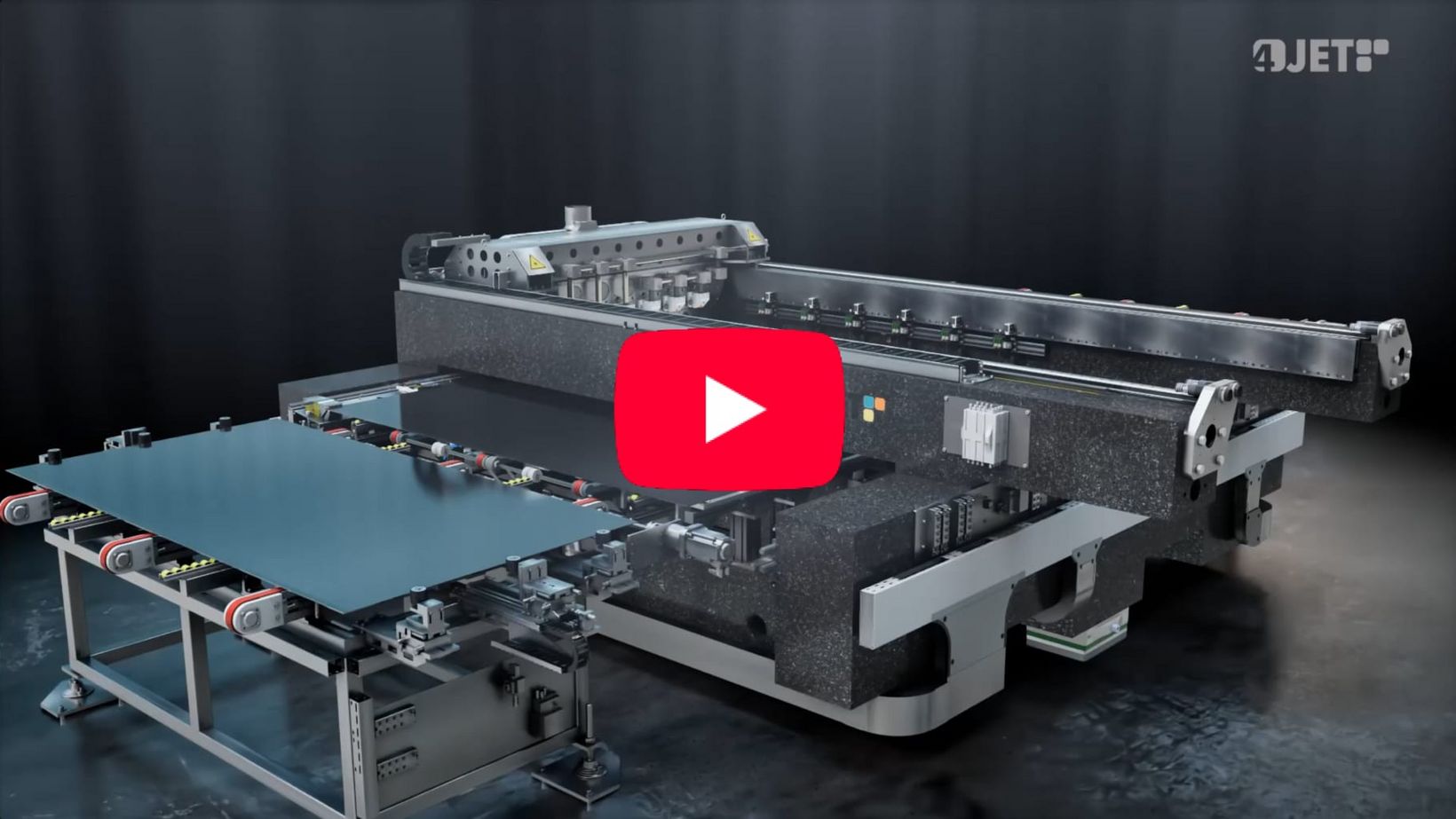

TOPAZ Px – Setting the Standard in Laser Scribing for PV Modules

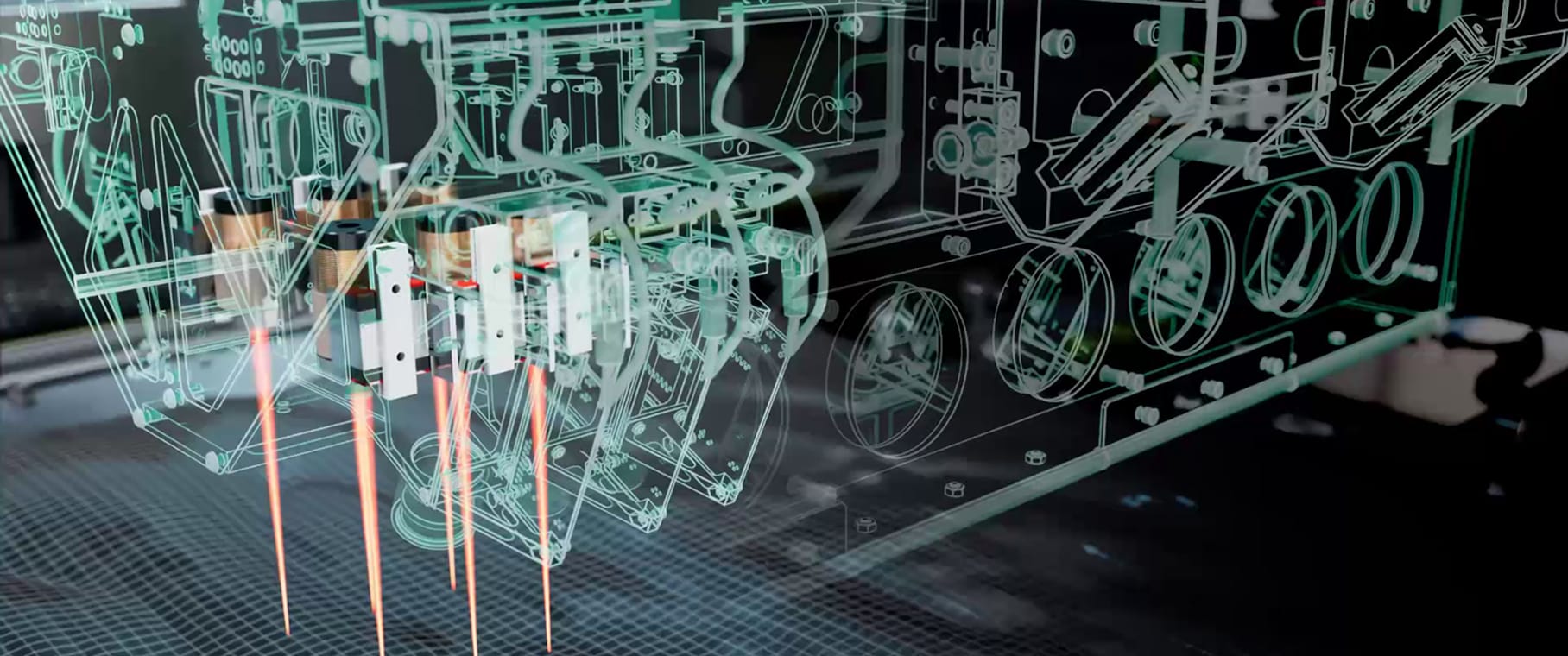

Laser Scribing re-invented

Highest possible precision

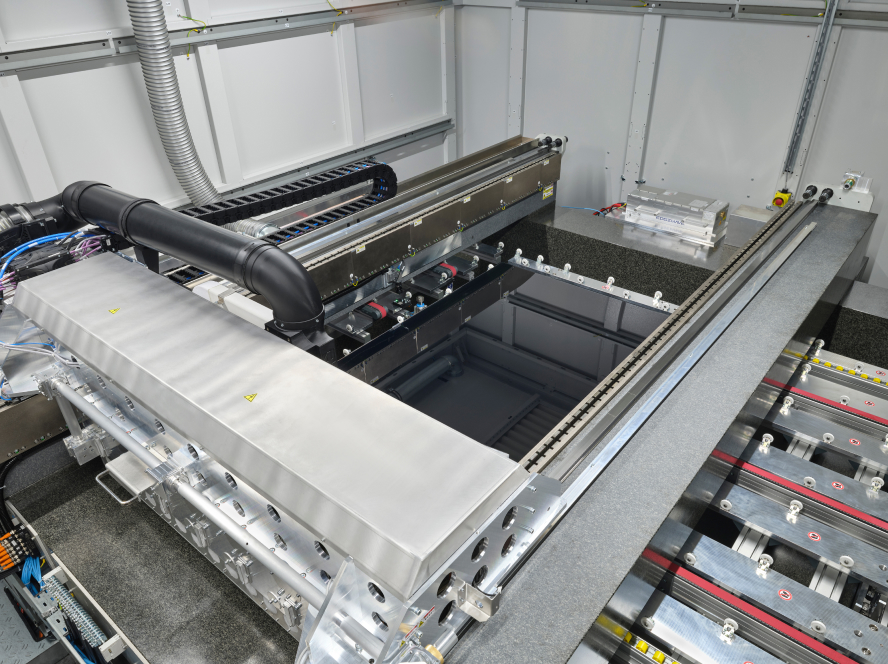

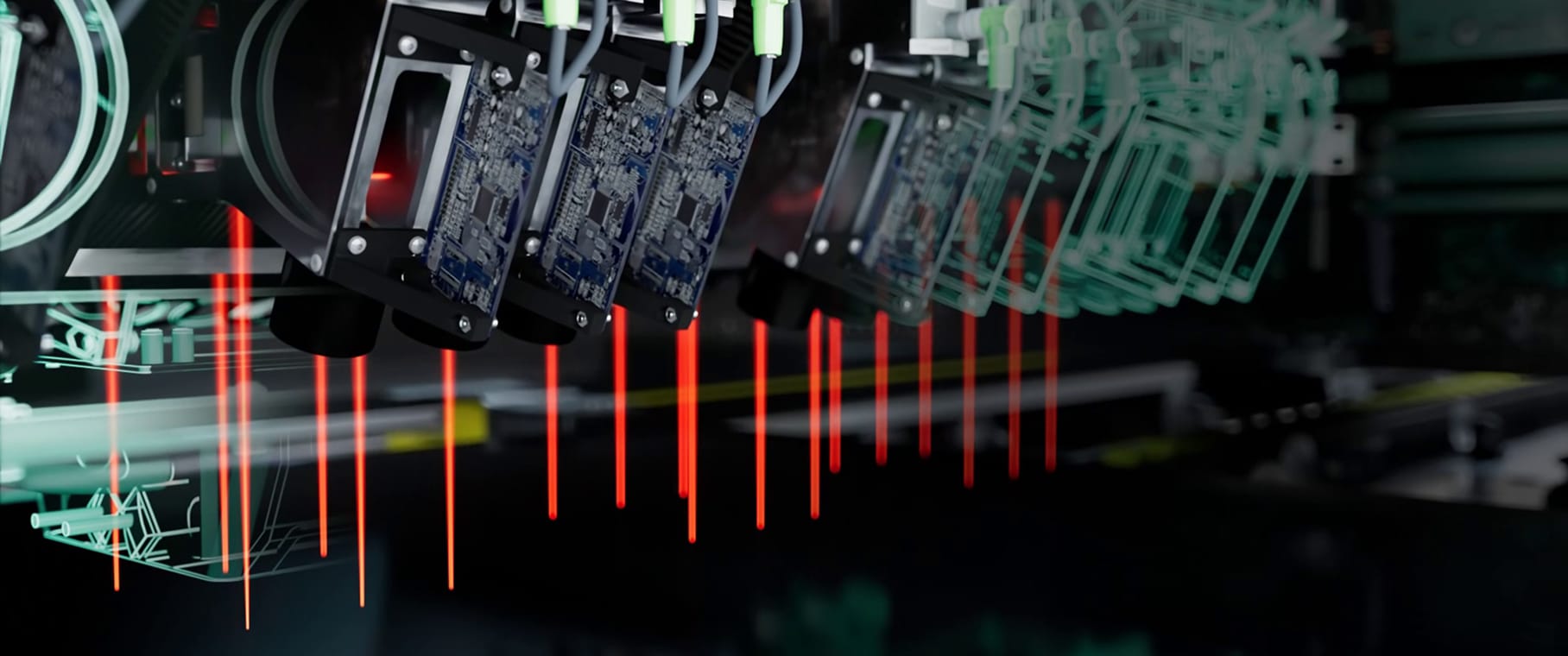

Up to 36 individual beams are generated from the laser, with every single one precisely monitored and regulated. This solution is unmatched on the market.

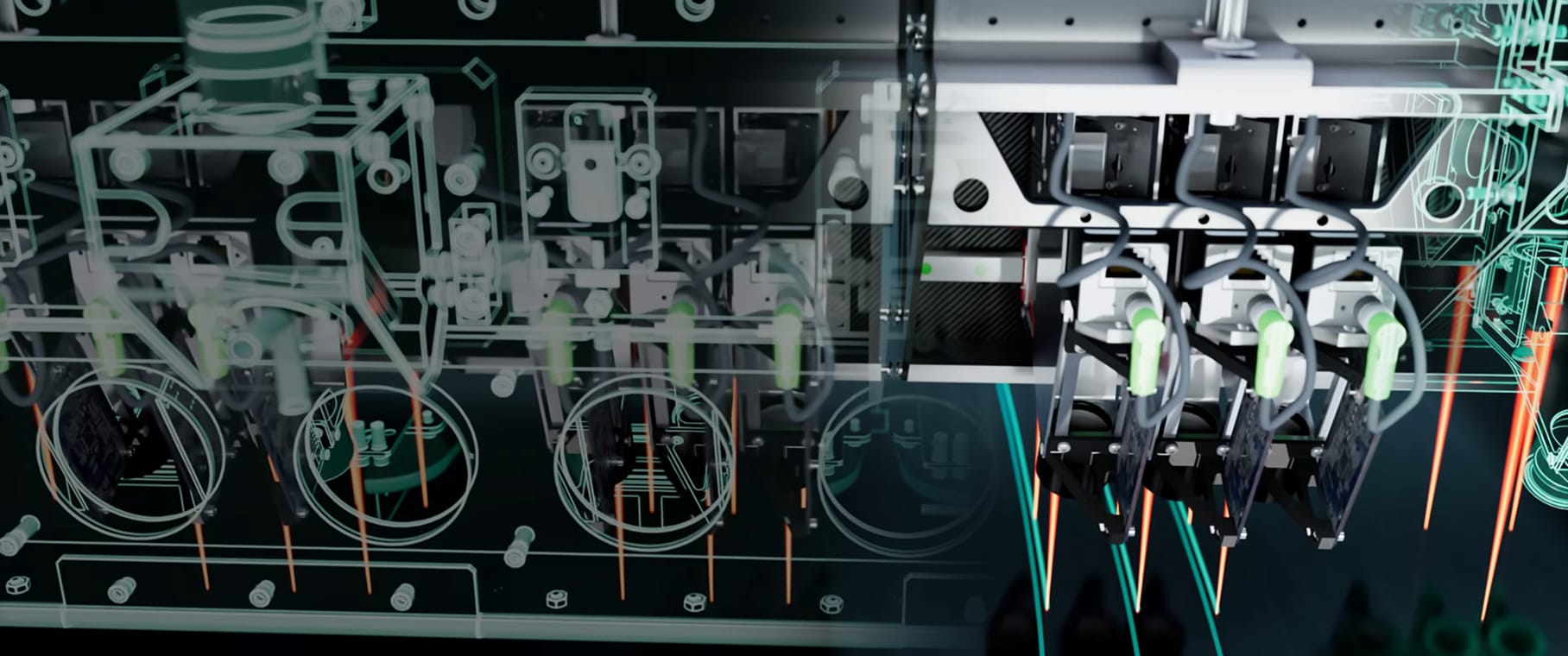

Cutting-edge components

Integrated path tracking, focus tracking and individual power control of each individual beamlet in minimal installation space.

Flexible pitch with just one click

The Core4 software and the system concept allow the scribe pitch to be individually adjusted between 3 and 10 mm.

TOPAZ Px compared to other systems:

Control of every single Beam

The laser beam is split into up to 36 individual beams (in groups of six beams each). Each beam can be individually monitored and controlled.

Path Tracking

The Path Tracking, in combination with the other closed loop controls, ensures the highest accuracy for each single scribe. The used vision system with a frame rate of up to 2 kHz and the dedicated high speed image recognition system are paramount. The final control quality depends largely on the required cycle time and the processing speed.

Focus Tracking

The laser focus Z positions can be adjusted to an accuracy of ± 50 µm and at a maximum closed loop cycle frequency of 35 Hz, ensuring consistent scribe quality at minimal response times. The final control quality depends largely on the required cycle time and the processing speed.

Power Balancing

An individual Power Balancing for each beamlet enables consistent scribing results and significantly reduces the laser power overhead.

Individual Pitch adjustment

TOPAZ Px offers the unique possibility to adjust the scribe pitch individually in the HMI software. Pitches between 3 and 10 mm are possible.

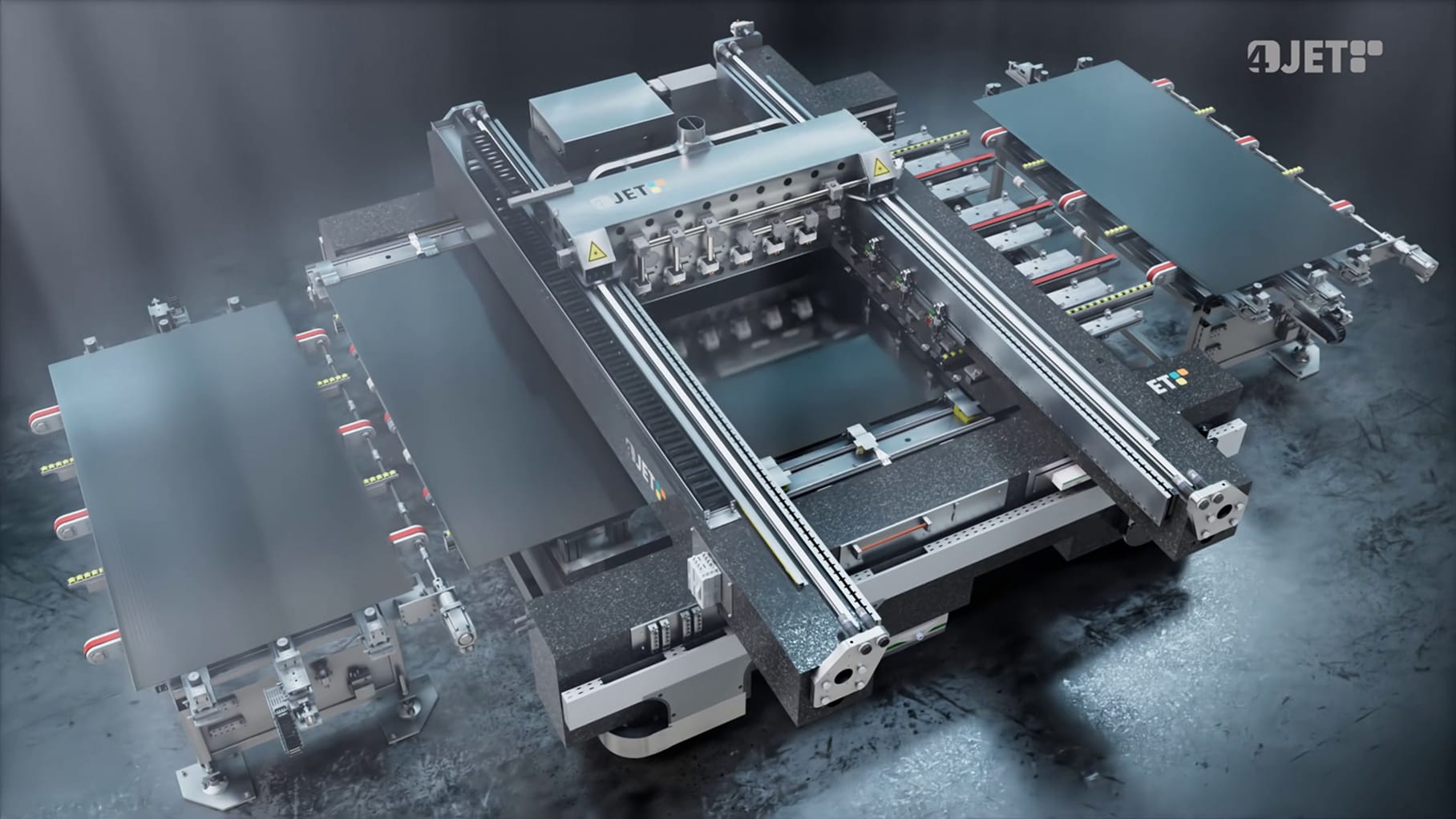

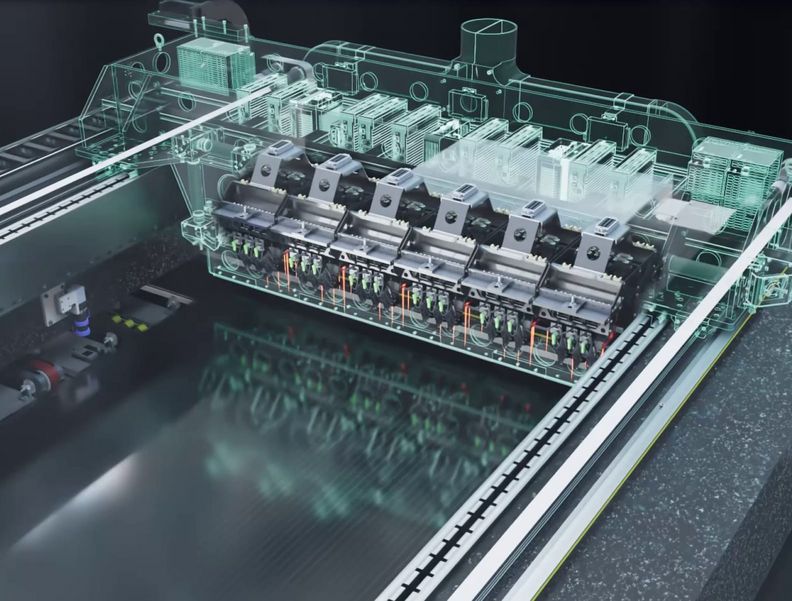

Modularity

The process head is designed so that you can freely choose from one scribe engine (with six individual beams) to six scribe engines. This allows the system to be individually adapted to your needs.

Maximum flexibility in recipe management

The high flexibility of laser processing in combination with our unique HMI software enables you to create or adapt recipes with minimal effort.

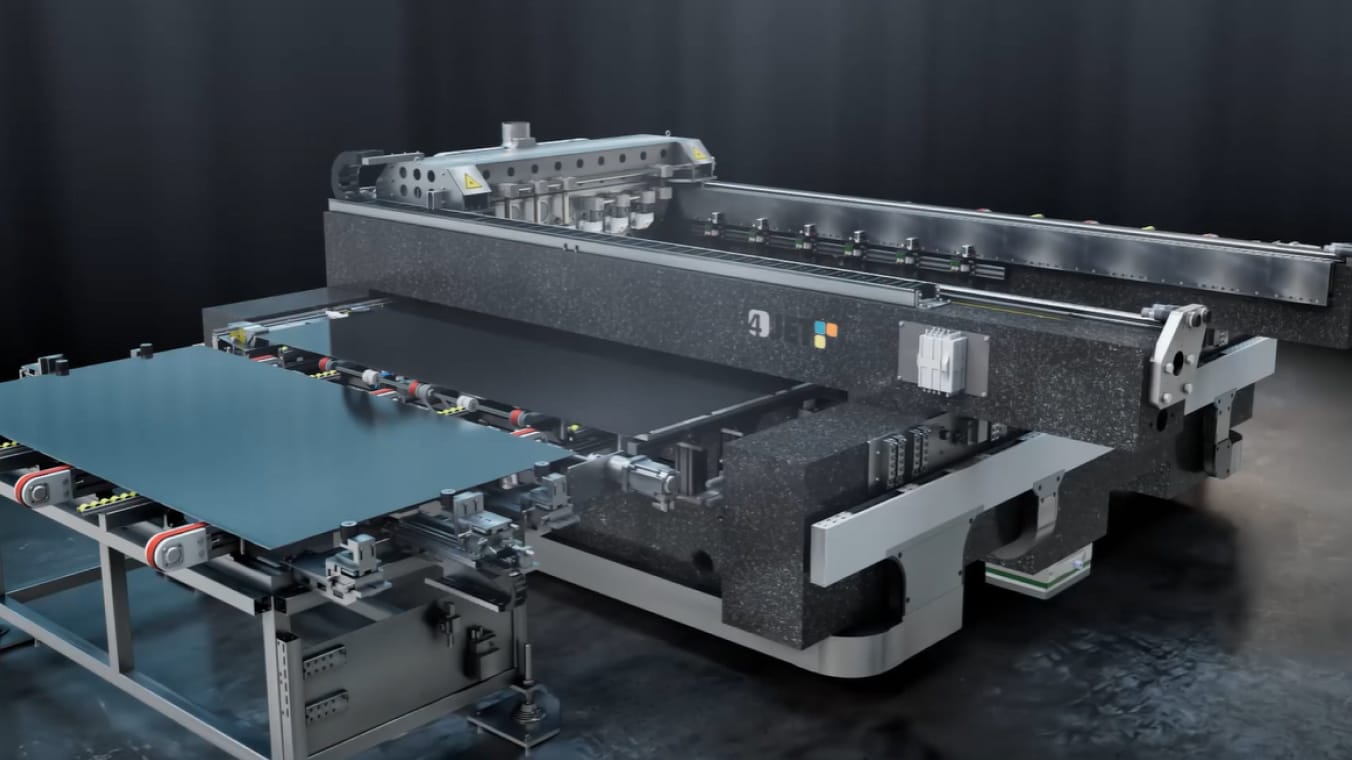

TOPAZ Px: Engineering Excellence in Every Detail

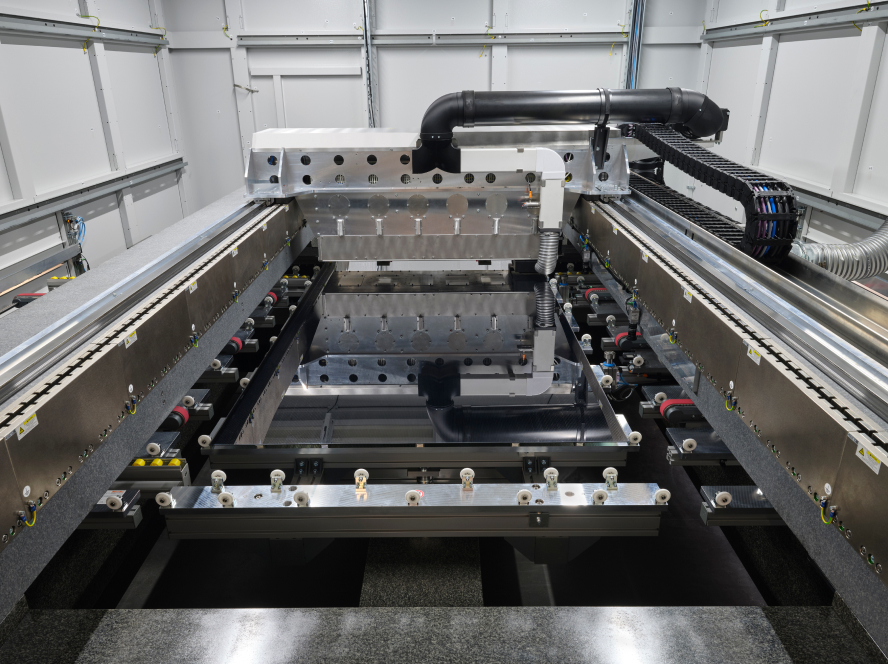

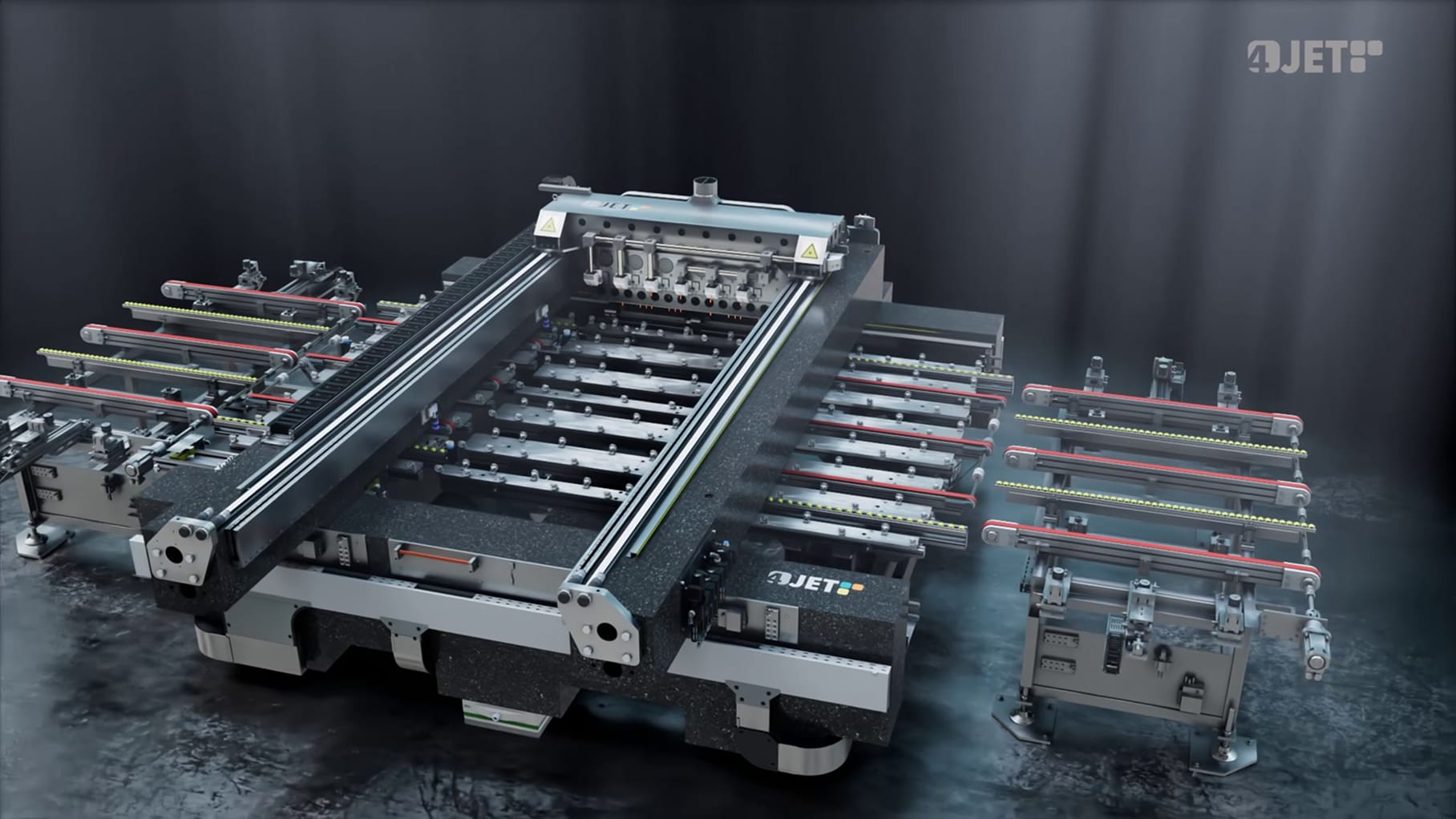

Conveyor System

The flexible conveyor belt system can easily be adapted to different substrate sizes. Transport speeds of up to 1000 mm/s are possible.

Gripper

For maximum precision, the substrate is securely held and guided by grippers throughout the laser process. Depending on cycle time demands, the system can be configured with one or two grippers.

Granite Base.

Granite is used for the system frame to reach the highest level of precision. It combines excellent thermal and mechanical stability with high mass, which helps to suppress vibrations.

Process Head

The process head is designed for speeds of up to 3.5 m/s. Taking acceleration and transport times into account, a fully equipped process head can produce up to 60 m of scribes per second. All this with individual path and focus tracking, power balancing, maximum pitch flexibility, a modular design, and the option of partial configuration.

Scribe engine

At the core of the TOPAZ Px lies its scribe engine technology. Whether configured with a single unit or up to six, each engine delivers outstanding performance. Benefit from features like individual Path and Focus Tracking, Power Balancing, and adjustable pitch offsets.

Our TOPAZ Px is used worldwide to manufacture more efficient thin-film photovoltaic modules with reduced dead zones.

System Specifications

| Category | Parameter | Value | Unit |

|---|---|---|---|

| Substrate | Max. substrate size | 2.350 x 1.250 | mm |

Glass thickness range | 2 – 3,2 | mm | |

| System | Scribe accuracy | ± 10 | µm |

Process | Scribe width | 20 to 100 | µm |

Wavelength | 355, 532, 1064 | nm |

Facility Requirements

| Category | Parameter | Value | Unit |

|---|---|---|---|

Electrical Energy (EE) | Line Voltage | 400(±10%) | V |

Frequency | 50(±1%) | Hz | |

Phases | 3 / N / PE | ||

Max. Current | 63 | A | |

Max. pre-Fuse | 100 | A | |

Average Power | 31 | kVA | |

Apparent Power | 50 | kVA | |

cos phi | ~0,8 | ||

Connection Type | Terminal, 25 | mm² | |

| Compressed Dry Air (CDA) | Pressure | min. 6,9 | bar |

max. 7,6 | bar | ||

Quality | Class 1 | ||

| Peak Flow | 200 | Nl/min |

Average Flow | 150 | Nl/min | |

| Connection Type | Festo tube Ø 12 | mm |

| Cooling Water | at 5 to 25°C and 3 to 5 bar | 14 | l/min |

Temperature | Operation | +21 … +22 (±1) | °C |

Storage | +5 … + 40 | °C | |

Humidity | Operation | (non-condensing) 40 … 60 | %rH |

Storage | 50 … 60 | %rH | |

Noise | operation | < 74 | dB(A) |

Floor | Floor flatness (max. compensation) | ±4 | mm |

Footprint / Weight

| Category | Parameter | Value | Unit |

|---|---|---|---|

Footprint | Main unit | 5.669 x 4.289 | mm² |

incl. Service Area1 | 11.724 x 7.581 | mm² | |

Height | Main unit | 3.695 | mm |

Electrical cabinet | 2.300 | mm | |

Weight | Main unit | 16,5 | t |

Electrical cabinet | 2,5 | t | |

Floor load | max. | 625 | kN/m² |

Avg. | 15,4 | kN/m² |

Ready to Upgrade Your Scribing Process?

Boost your production quality, reduce downtime, and lead your market with TOPAZ Px – the most advanced laser scribing system for thin-film module processing.

FAQ – Laser scribing with the TOPAZ Px

When manufacturing PV modules, the TOPAZ Px can be used to create P1, P2, or P3 scribes. The Px is generally suitable for processing thin-film modules.

The precision and stability of the scribing process directly influences the dead zone and thus the efficiency of the PV module. One of the most important factors, however, is that the active beam adjustment can reduce the error rate and rejects, such as crossing scribes, to almost zero. In addition, the performance of the produced panels is consistently high. This significantly reduces your production costs.

Our system is compatible with CdTe, Perovskite, and CIGS thin-film modules.