Life Sciences

Enabling Precision in Diagnostic, Analytical, and Microfluidic Glass Components

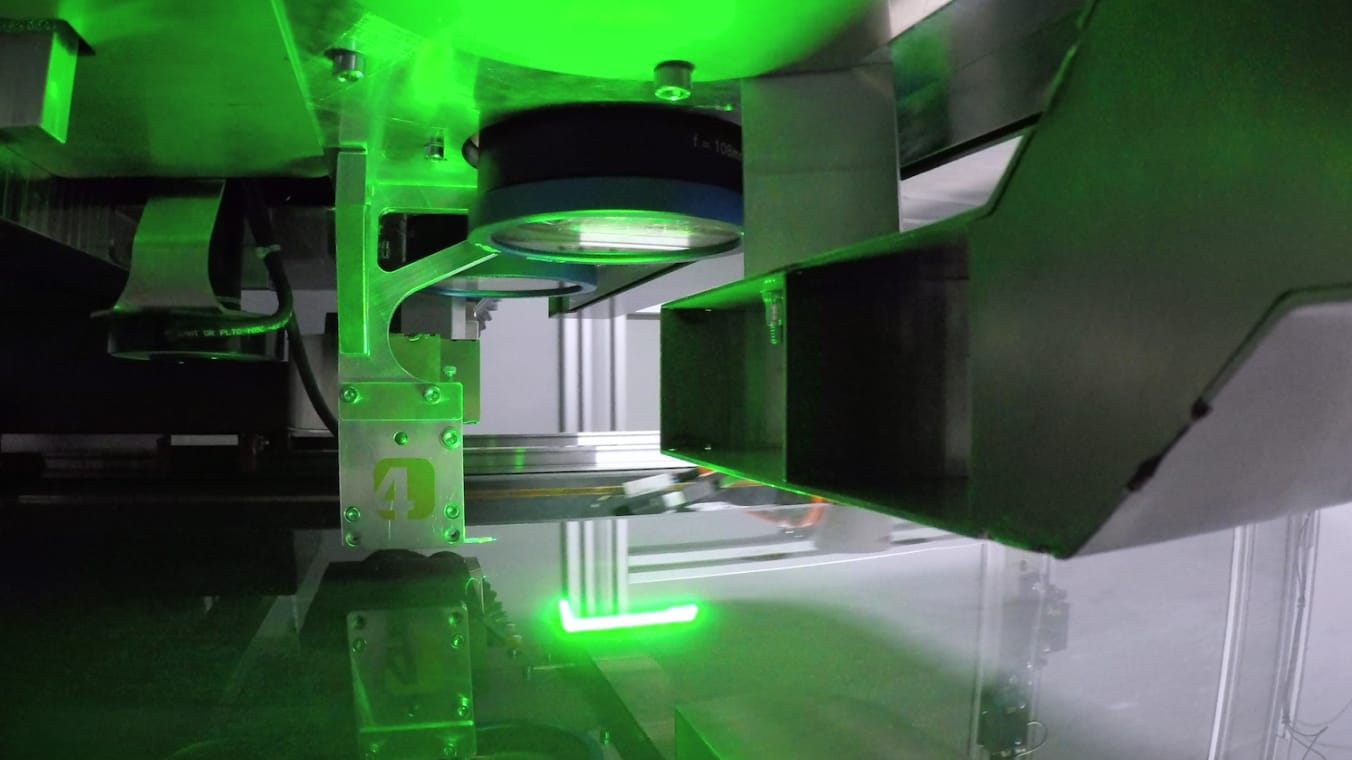

From lab-on-glass chips to biosensors and analytical optics, our laser micromachining platforms enable precise, non-contact structuring of glass components used in life science instrumentation and diagnostics.

Glass as a Functional Substrate in Life Sciences

Glass is an essential material and widely used in life sciences for its chemical resistance, optical clarity, and biocompatibility. Applications such as microfluidic devices, diagnostic cartridges, lab-on-chip platforms, and cell culture chambers require ultra-precise microstructuring, drilling, and channel formation – often on thin borosilicate or fused silica substrates.

Conventional mechanical techniques introduce microcracks, contamination, and yield losses. Our laser-based micromachining platforms enable cleanroom-compatible, contactless, and high-throughput processing for both R&D and volume production environments.

Key Technical Features for Life Sciences Glass Processing:

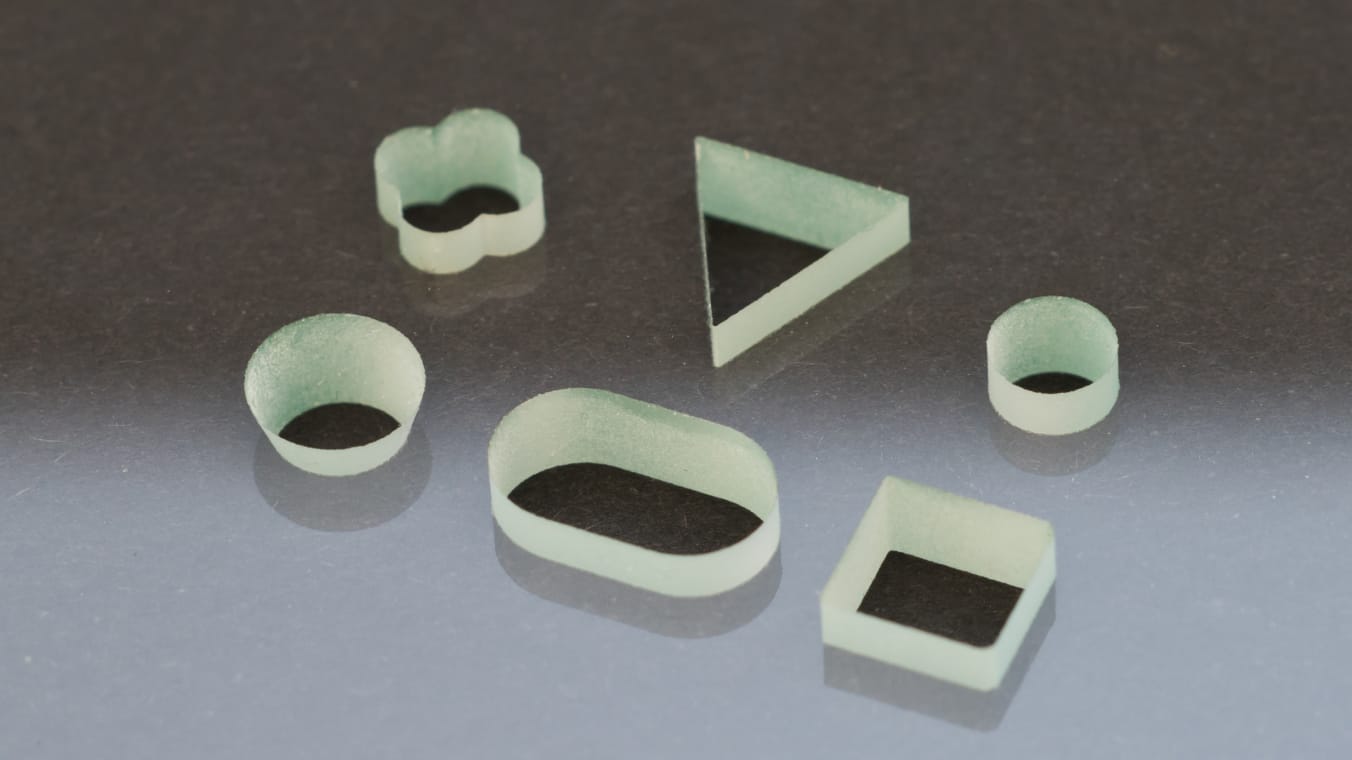

Drilling & Feature Machining in Diagnostic Glass

Applications:

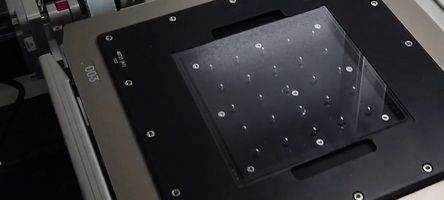

- Micron-scale holes for reagent inlets, vents, or sample loading zones

- Creation of channels, chambers, ports, and microstructures in glass

- Applied in disposable diagnostic cassettes, slide-based assays, or biosensor platforms like lab-on-chip systems, DNA analysis, and point-of-care testing

4JET Technology Fit:

- USP micromachining for precision-controlled microstructures with clean, crack-free edges

4JET Solution:

- Contactless, debris-free processing with tight dimensional tolerances for cleanroom production

4JET Platforms:

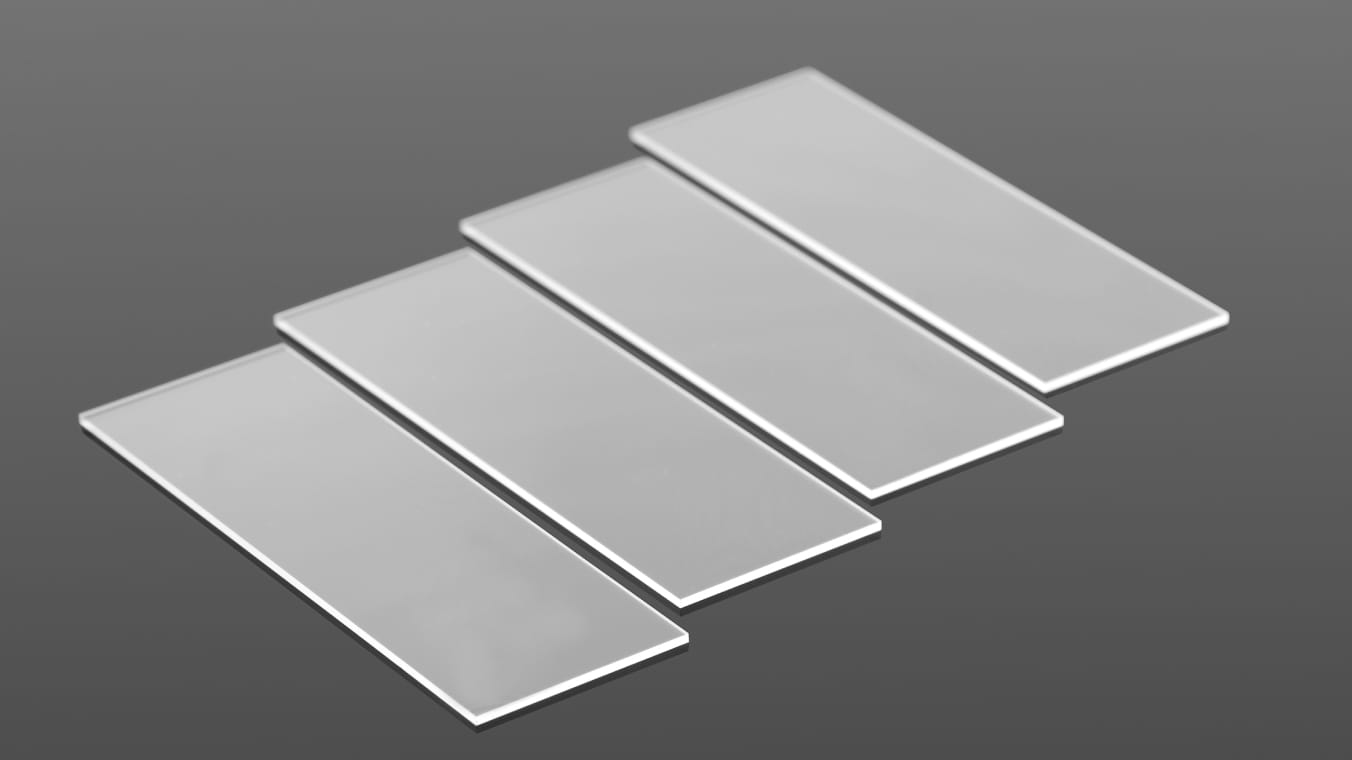

Glass Substrate Cutting & Dicing for Diagnostics

Applications:

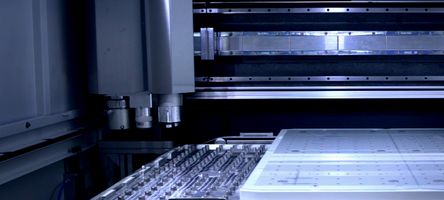

- Singulation of diagnostic slide arrays and biosensor wafers

- Dicing of borosilicate or fused silica substrates for lab-on-chip devices

- Used in high-throughput diagnostics or bioMEMS platforms

4JET Technology Fit:

- Bessel beam laser cutting for chip-free edges, low particle generation, and high edge strength

4JET Solution:

- Clean, stress-free, and reliable wafer singulation – ideal for downstream bonding and assembly

4JET Platforms:

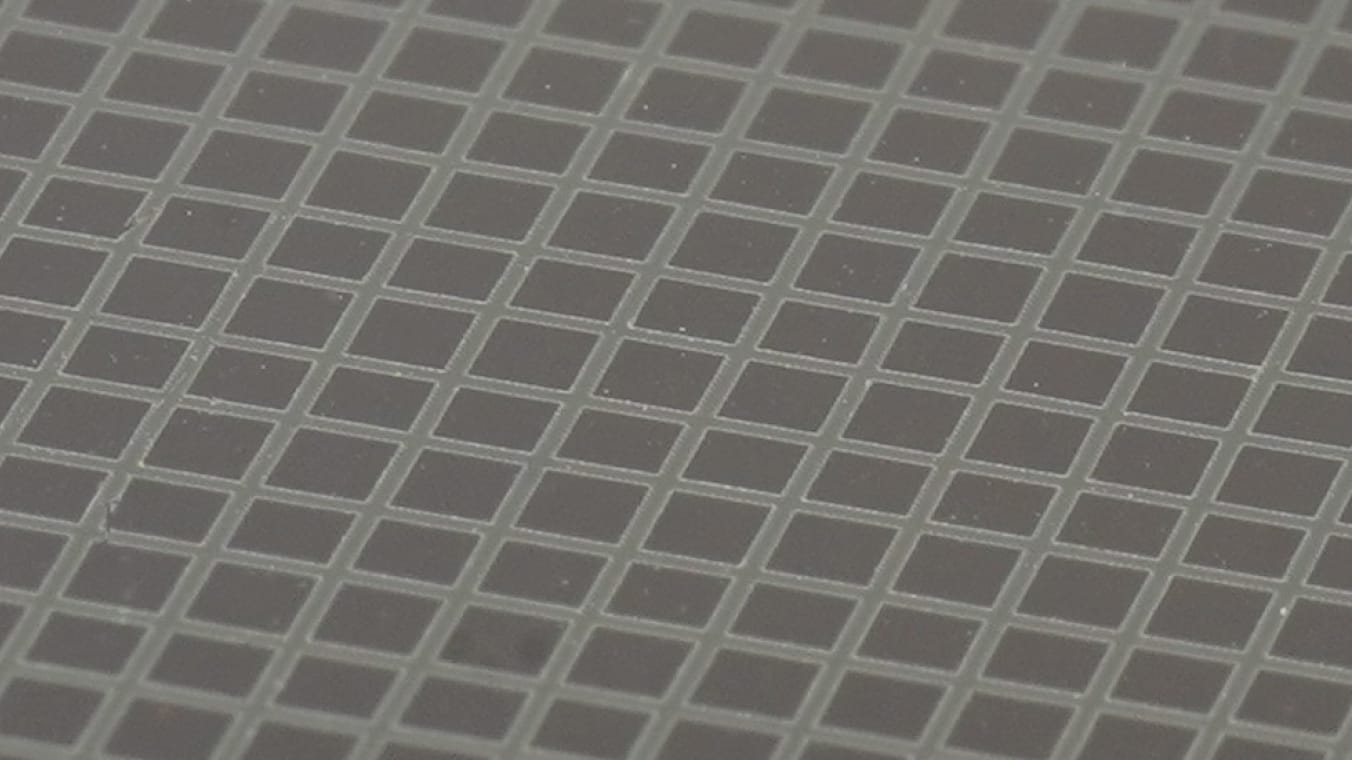

Drilling of Access Ports and Vias

Applications:

- Ventilation holes, reagent inlets, and sample ports

- Alignment with pre-defined microfluidic paths or sensing areas

4JET Technology Fit:

- Ultrashort pulse laser drilling for high-aspect-ratio, taper-free microfeatures

4JET Solution:

- Sub-millimeter holes with high repeatability – free of heat-affected zones or cracks

4JET Platforms:

Surface Treatment for Optical and Biofunctional Zones

Applications:

- Wettability patterning, bonding zone definition, or fluorescence zones

- Selective coating removal for optical detection or functionalization

4JET Technology Fit:

- Layer-selective ablation and high-resolution laser texturing on coated or chemically treated glass – enabling precise control of geometry and surface wetting behavior

4JET Solution:

- Precise surface engineering without affecting underlying layers – ideal for sensor integration

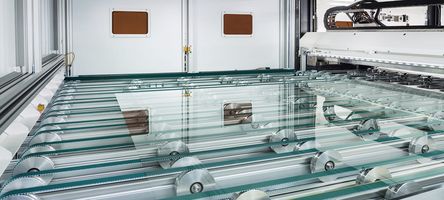

Cutting and Shaping of Glass Substrates

Applications:

- Shaping thin glass carriers for test kits or diagnostic cartridges

- Format trimming for disposable or sterilizable labware

4JET Technology Fit:

- Bessel beam cutting for thin, coated, or patterned glass

4JET Solution:

- Micro-crack-free edges with no need for post-polishing – suitable for disposable or sterilizable glass formats

4JET Platforms:

Microfluidic Channel Structuring

Applications:

- Creation of flow paths, capillaries, or mixers in lab-on-glass chips

- Ideal for POCT, sequencing, or immunoassay applications

4JET Technology Fit:

- Direct-write grayscale or binary ablation of surface channels

4JET Solution:

- Custom fluidic geometries with high resolution and reproducibility

Why 4JET?

Cleanroom-ready micromachining platforms for lab-on-glass and diagnostics

Proven technology used in biosensors, DNA chips, and fluidic testing devices

Sub-10 µm accuracy with minimal heat, particles, or deformation

Flexible platform architecture from R&D to inline production

Innovating with Glass in Life Sciences?

Let’s explore how our laser platforms can support your microfluidic, diagnostic, or bioanalytical application.

Enabling Capabilities Across All Life Science Applications

Precision, sterility, and repeatability are key to laser applications in life sciences. We provide high-end system capabilities that empower manufacturers of lab-on-chip devices, biosensors, diagnostic consumables, and analytical substrates – from R&D to full-scale production.

Core4 Software Platform Global Services & SupportAutomation Integration

Core4 Software Platform

Every 4JET life sciences solution runs on Core4 – our modular software backbone that ensures process security, flexibility, and traceability.

- Intuitive user interface for quick process setup, even in regulated environments

- Modular library for laser control, automation, and vision tools

- AI-powered inspection for microfluidic features and critical dimensions

- Full traceability and process logging for compliance and GMP integration

Automation Integration

From prototyping platforms to inline production – automation-ready:

- Robotic handling of delicate substrates (e.g. ultra-thin glass or polymer foils)

- Cleanroom-compatible motion systems and integration with dispensing/testing units

- MES-ready interfaces for regulatory process control

Innovating with Glass in Life Sciences?

Let’s explore how our laser platforms can support your microfluidic, diagnostic, or bioanalytical application.