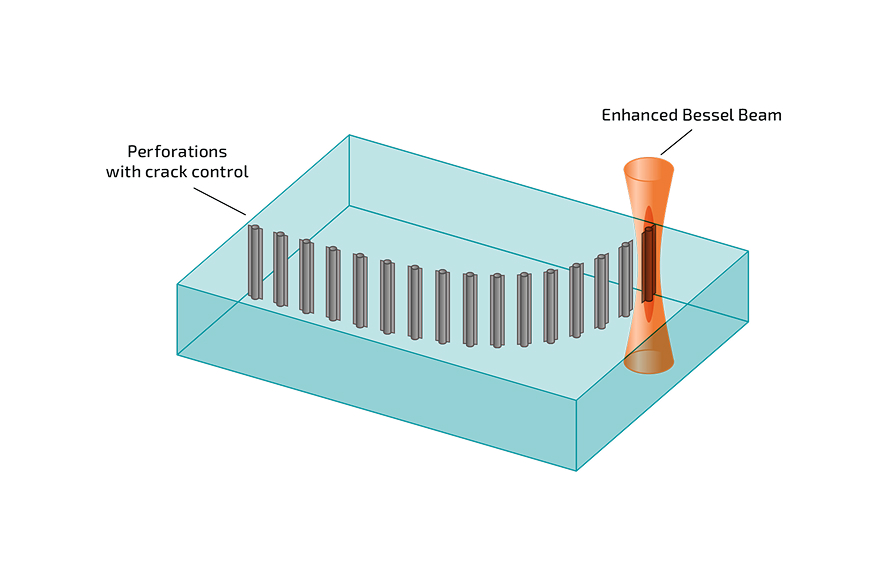

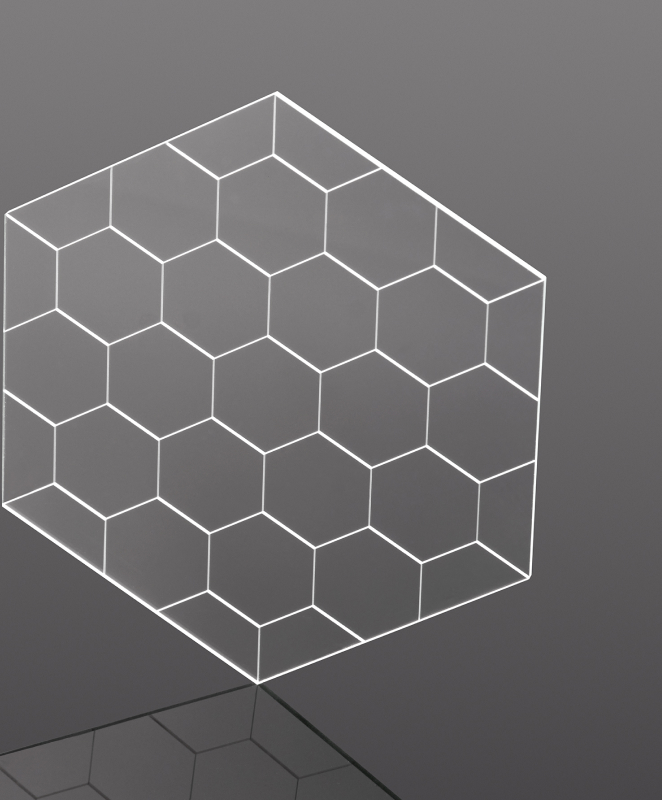

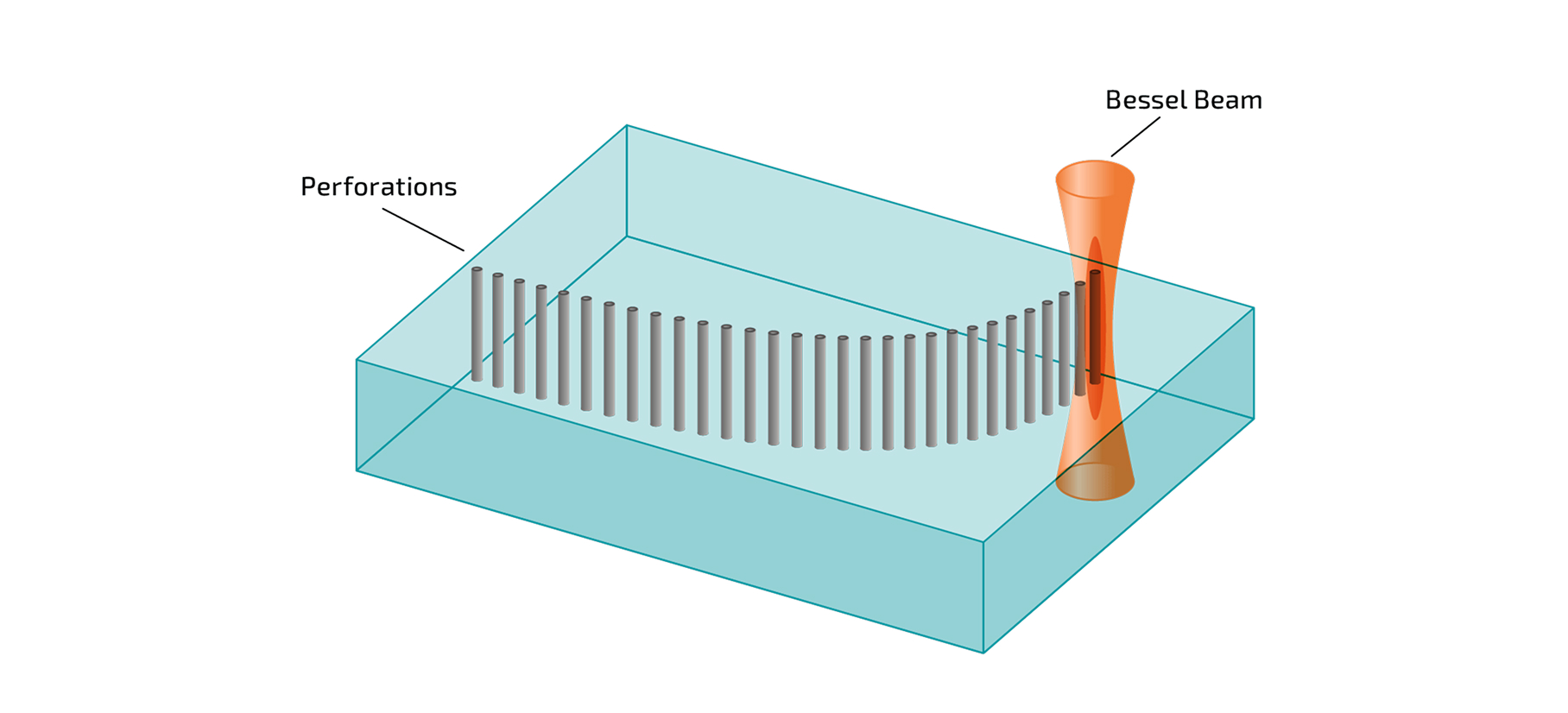

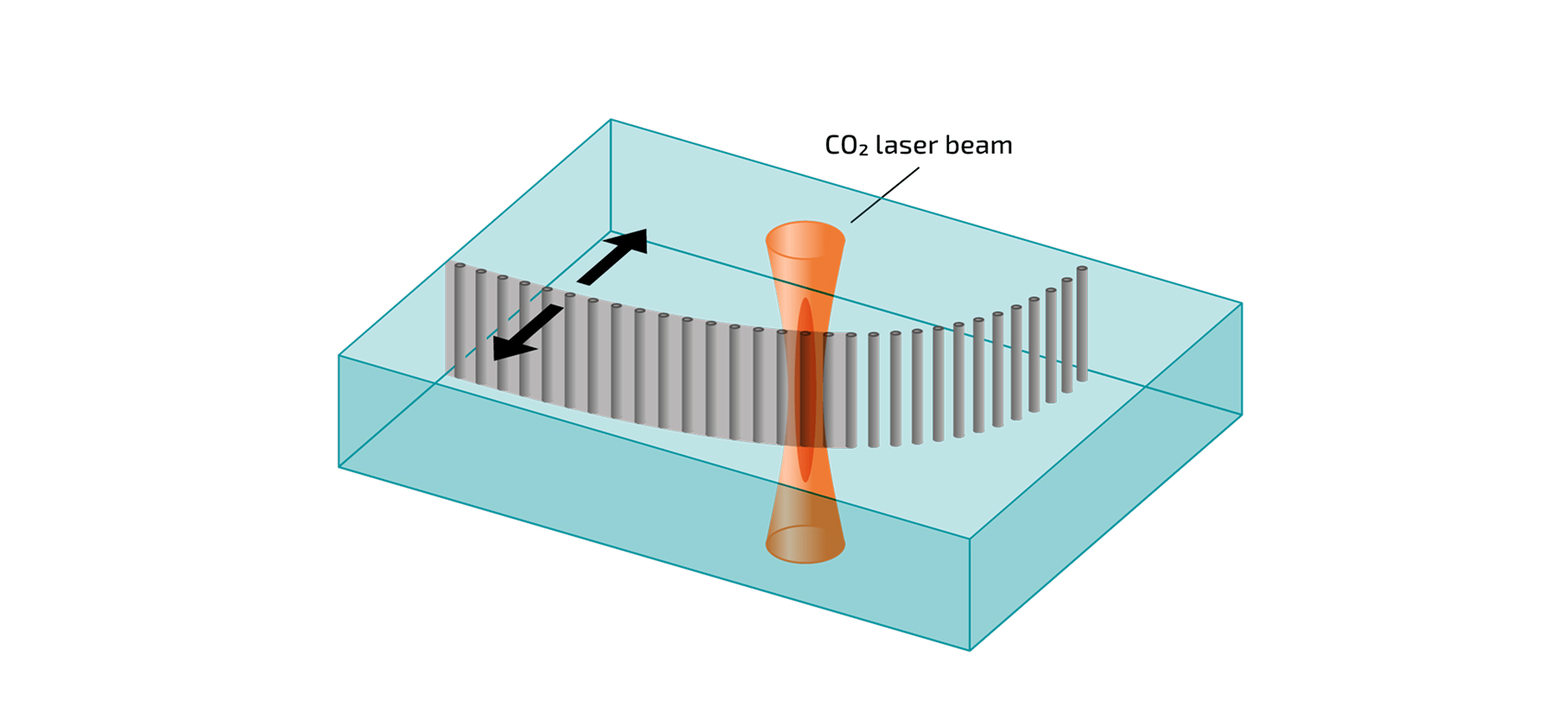

Laser glass cutting is a high-precision, contact-free process for separating glass. We use innovative laser processing based on a Bessel beam – a specially shaped laser beam with an extended focus zone that can penetrate the glass particularly deeply and evenly.

Next-Generation Glass Manufacturing

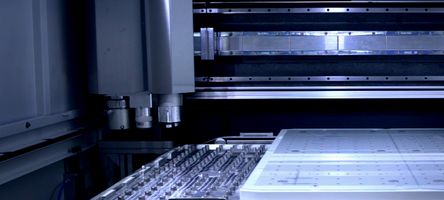

Laser glass cutting represents a paradigm shift in industrial glass processing. The contactless, high-precision process is increasingly replacing mechanical cutting methods – not only because of its superior cutting quality, but also due to its process reliability, flexibility, and cleanroom suitability. Whether ultra-thin glass, tempered substrates, or complex geometries: With technologies such as nanoPerforation and Enhanced nanoPerforation, even the most demanding requirements can be reliably met.

For industries such as microelectronics, medical technology, display manufacturing, and architectural glass, we offer solutions that enable the economical and sustainable production of innovative products.

The Cutting Process Takes Place in Two Steps:

1. nanoPerforation:

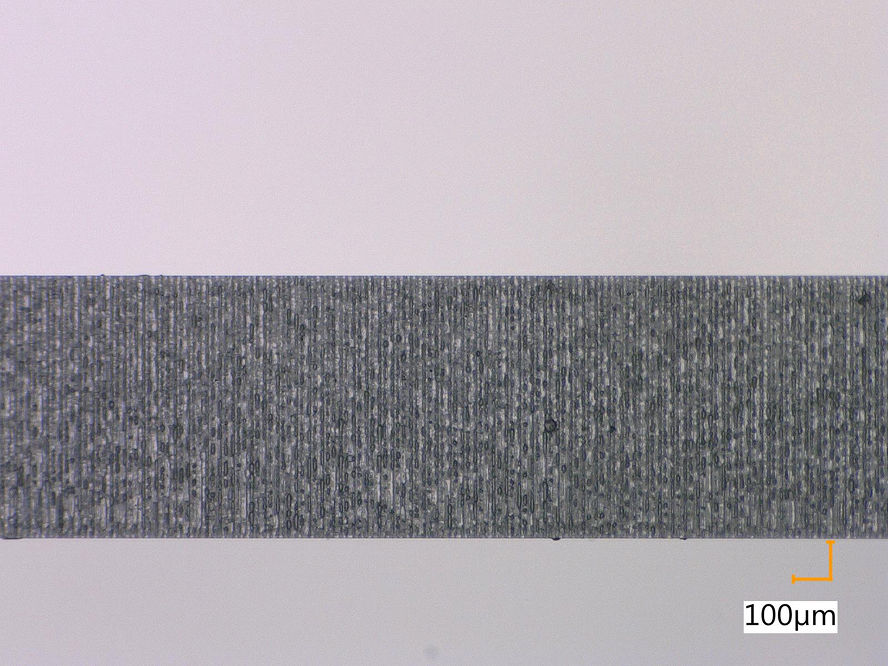

A pulsed laser source with pulse durations in the range of a few picoseconds generates a series of microscopic modifications in the glass volume along the desired cutting contour. The modifications typically have a diameter of around 1 µm and a length that extends across the entire thickness of the glass. They are created by nonlinear absorption processes and, when lined up, result in a predetermined breaking path in the material – without mechanically damaging or thermally stressing the surrounding material.

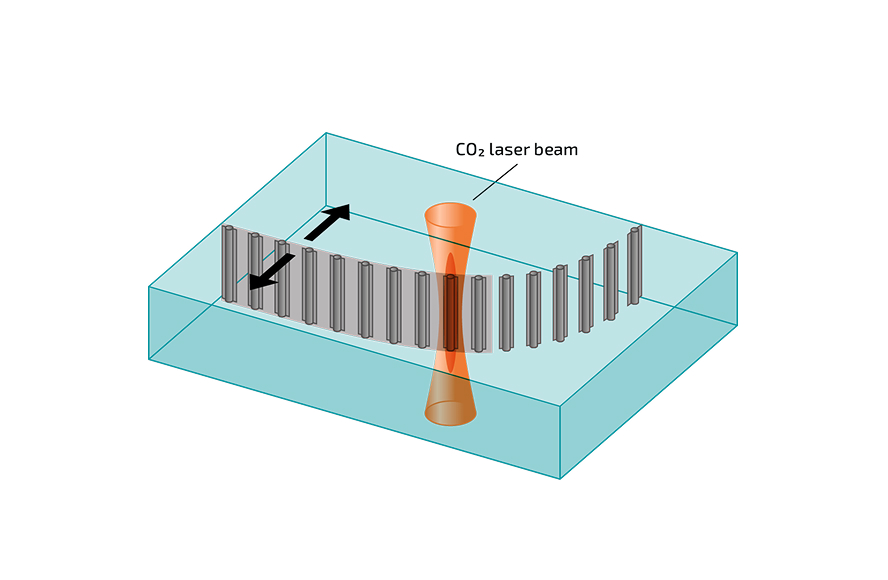

2. Thermal separation:

The glass is then subjected to well-dosed thermal stress, typically by controlled heating and cooling along the modification line. A CO2 laser source is particularly well suited for this purpose. The stress occurring during heating and cooling causes the glass to separate precisely along the previously created nanoPerforation.

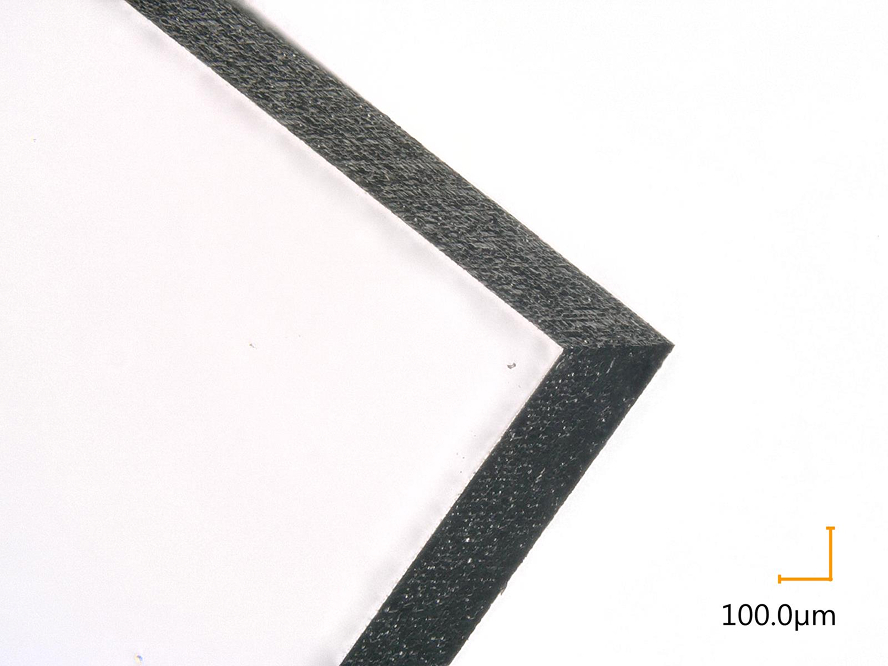

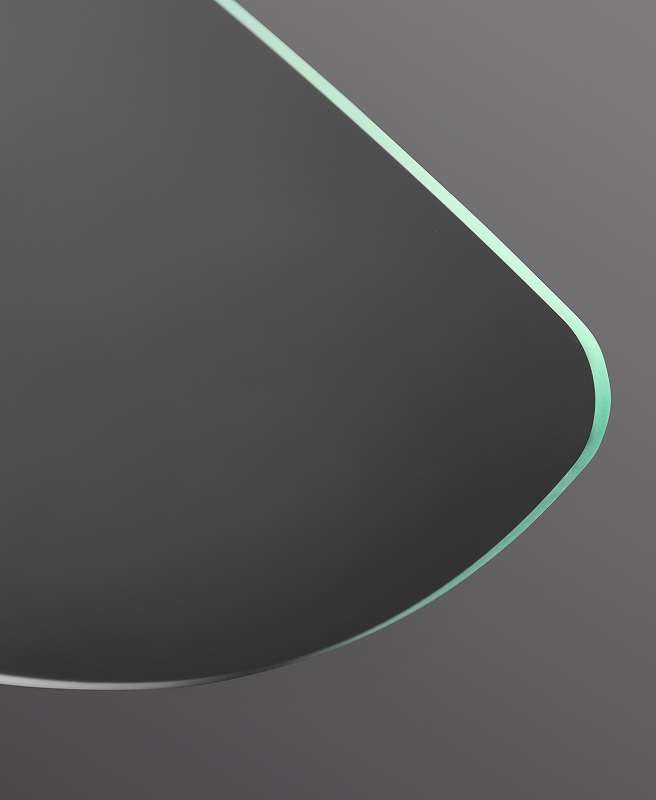

This process enables highly precise, low-particle, and stress-free cutting results, even for delicate or hardened types of glass. The cutting edge roughness achieved is Ra < 1 µm, which enables outstanding surface quality without post-processing. It is ideal for applications where the highest quality and minimal material stress are required, such as in microelectronics, medical technology, or display manufacturing.

We offer two variants of this process:

nanoPerforation (nP):

The standard solution for precise, clean cuts with high process reliability.

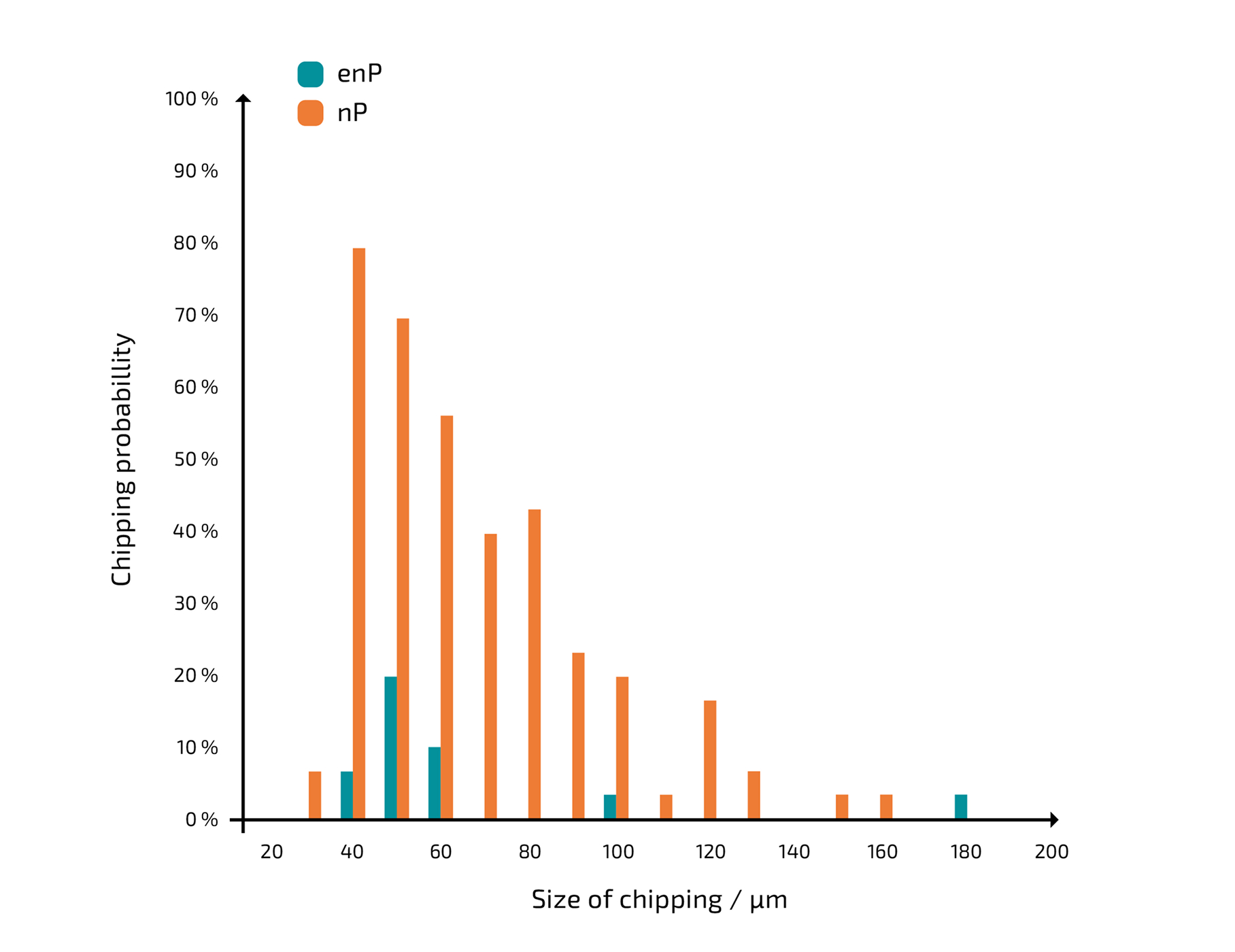

Enhanced nanoPerforation (EnP):

Our advanced technology offers the following

- Higher edge strength, which is permanently maintained thanks to optimized separation.

- Significant reduction in chipping – the amount of breakouts is reduced by a factor of ten.

- Greater geometric flexibility, even with complex cutting patterns and small radii (up to 300 µm).

- Higher process speed, ideal for industrial high-throughput applications. Depending on the application, cutting speeds of up to 1500 mm/s are possible, e.g. when processing large-format soda-lime glass panes.

4JET holds more than 60 patent families including several 100 individual international patent rights covering fundamental process technology for laser based glass machining and products derived from these. The portfolio includes the use a of a non-diffractive, line shaped or Bessel beam for glass cutting, special release and inside contour cutting processes as well as a vast range of additional claims. Contact 4JET to discuss potential license arrangements.

Comparison between Laser Glass Cutting and the Mechanical Cutting Process

A comparison with mechanical glass cutting shows clear advantages of the laser process:

| Criterion | Laser Glass Cutting | Mechanical Cutting ("Scribe and Break") |

|---|---|---|

| Precision | Very high, follows the positioning accuracy of the system. Ideal for complex and fine structures | High for straight grid geometries. |

| Edge Strength | High, cut edges can often be used without reworking | Low, reworking usually required |

| Microcrack Formation | Very low, short and controllable crack zones | Microcracks and chipping possible, depending on the material |

| Particle-free | Low-particle processing, suitable for clean room applications | Particle formation possible, depending on the material |

| Material Utilization | High material utilization thanks to precise cuts and minimal losses (nesting) | High material utilization. Nesting not possible. |

| Geometric Flexibility | Free-form geometries and complex contours possible | Only linear or simple geometries can be realized |

| Maintenance | Low, as there is no tool wear | High, regular tool changes necessary depending on the material |

Both methods offer distinct advantages – we would be pleased to advise you on which one is better suited to your specific application.

Fields of Application for Laser Glass Cutting

Laser glass cutting is used in numerous industries, especially where maximum precision, cleanliness, high edge hardness, and quality are required. These properties not only improve product life and yield, but also enable complex geometries, low-particle processes, and maximum cutting quality – from medical technology and microelectronics to architectural glass.

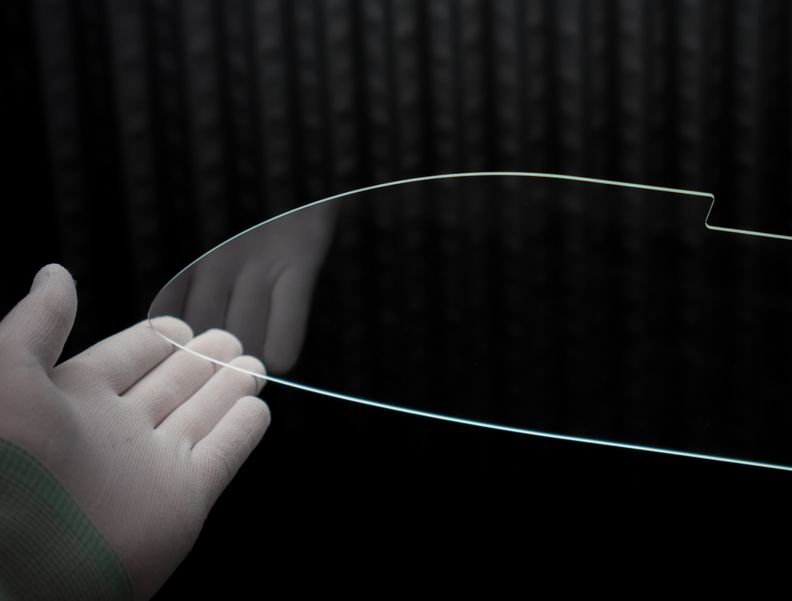

Thin glass for modern touch and cover displays is processed with the highest precision. Our laser process significantly reduces microcracking, which greatly improves the mechanical stability, optical quality, and further processability of the glass – a decisive advantage for demanding applications in display manufacturing.

For intelligent glazing in buildings or vehicles where high-quality, functional coatings have already been applied, a reliable and clean cutting process is crucial. Our laser process enables controlled partial cutting –i.e., the targeted cutting of the glass without complete separation. This technology is particularly important for applications where functional layers must be preserved or downstream processes such as selective breaking are planned.

Rearview mirrors, HUD displays, and sensor covers require precise and reliable cutting quality. A particular advantage is the high edge strength, which often eliminates the need for post-processing of the cut edge – a clear efficiency gain in automated manufacturing processes in the automotive industry.

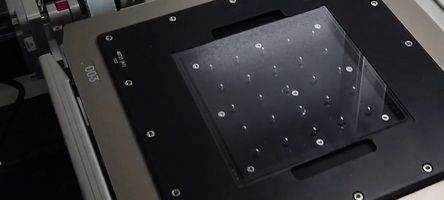

Maximum precision is essential in semiconductor manufacturing and in the production of sensitive sensor components. Our process enables the cutting of special glasses (ultra-thin glass, wafer glass) with high dimensional accuracy, while also offering low-particle processing that is ideal for cleanroom applications and sensitive structures.

Many innovations in lab-on-a-chip applications and microfluidic components have only been made possible by laser glass cutting, as the disadvantages of other cutting processes do not allow for economically viable implementation.

Lenses, filters, encoder discs, and other optical components require smooth cut edges without thermal stress. Compared to traditional methods, precise and clean process control reduces the costs of reworking and cleaning.

FAQ: Laser Glass Cutting with 4JET nanoPerforation Technology

Yes, with our patented nanoPerforation, it is possible to cut chemically hardened glass precisely and reliably. Thermally hardened glass can also be processed in certain cases, depending on the glass thickness, stress distribution, and application scenario.

The component precision follows the positioning accuracy of the machine platform and is in the single-digit to double-digit micrometer range. This accuracy is crucial, especially in applications such as microelectronics or optical components.

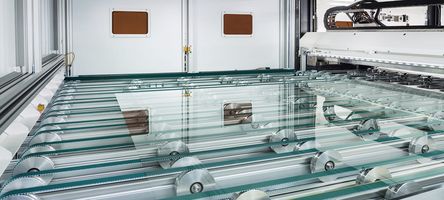

Yes, our laser systems can also cut large-format glass sheets up to 2250 mm x 3700 mm – ideal for architectural glass or solar panels. Depending on the type of glass (e.g., soda-lime glass), cutting speeds of up to 1500 mm/s are possible.

Borosilicate glass, thin glass, float glass, and other technical glasses are best suited. Suitability depends on the glass composition and thickness. Glass thicknesses up to 4 mm, and in special cases even thicker glass, can be processed without any problems in automated operation.

Laser glass cutting offers a number of technical advantages over mechanical processes such as "Scribe and Break": The high edge hardness and very low microcrack formation ensure strong cut edges that in many cases do not require post-processing. The process is also low in particles, making it ideal for sensitive applications such as clean room production. In addition, the laser process enables free-form geometries to be cut with high precision and results in less material loss, as higher material utilization is possible.

This is a process in which glass is separated by applying targeted thermal stresses along a line.

Yes, particularly thin glass (< 100 µm) can be cut very gently and precisely with a laser – a clear advantage over mechanical methods.

Yes, we offer industrial laser machines with an integrated glass cutting process. Our solutions can be seamlessly integrated into existing production lines or used as standalone systems.

The costs depend on various factors such as glass type, thickness, geometry, and the desired degree of automation. We would be pleased to provide you with a customized quote or perform an ROI calculation based on your application.

Our laser systems only require electricity, water (PCW), and compressed air (CDA) – no special operating media or complex infrastructure measures are required. In addition, the systems are designed so that they can be operated by trained personnel without special laser knowledge – ideal for use in an industrial environment.

In cases where thermal separation is not possible or practical, we offer a precise mechanical breaking process as a supplement – economical and reliable for many types of glass.