Perfect Adhesion Through Laser Cleaning

Typically, release agents, oils, oxides or contaminations are removed without residue and contact points are specifically prepared for further processing. By selecting suitable process parameters and tailor-made beam shaping, the surface structure remains undamaged in contrast to abrasive processes and the process is more environmentally friendly than wet chemical cleaning. Automation controls ensure a continuous level of highest quality in the cleaning result.

A Perfectly Cleaned Inner Liner Provides the Foundation for Applying Value-Enhancing Functions:

- Self sealing materials

- Noise reduction foams

- RFID transponders

Laser Cleaning Offers Several Advantages When Preparing Surfaces Bonding

- Repeatable precision cleaning for safe bonds

- Dry process - without blasting media or wet chemicals

- Significantly more compact footprint than washing machines

- Environmentally friendly process

- Inline integration

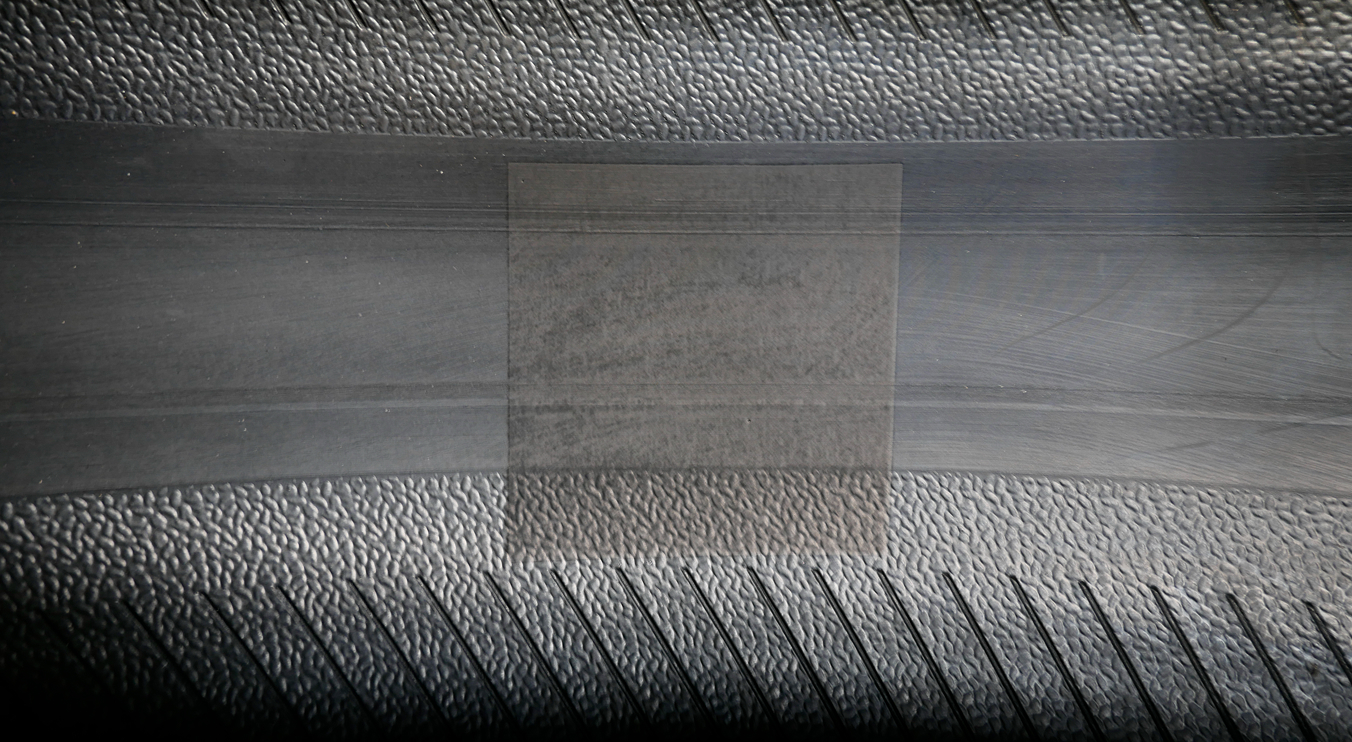

Targeted Cleaning Instead of Full Surface

Only clean where it is really necessary: Instead of treating the entire inner liner, precise cleaning is applied to only defined areas. This not only saves considerable investment costs, but also valuable cycle time. Ideal for the integration of RFID or intelligent sensor systems – efficient, flexible, and perfect for the production of modern high-tech tires.