TOPAZ LD – The Benchmark in Laser Decoating

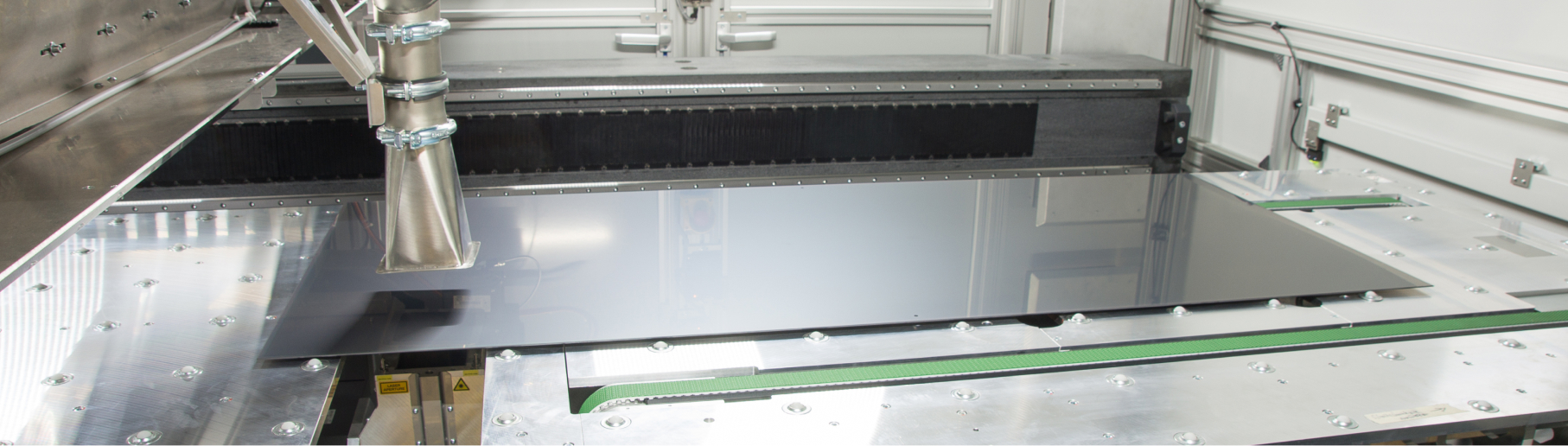

TOPAZ LD is our next-generation laser decoating system designed for laser edge deletion or large-area, high-precision ablation of functional layers on glass.

Engineered with cutting-edge components, it delivers unmatched efficiency and accuracy – making it the preferred solution for processing PV modules, architectural glass, and automotive glazing.

Whether you are processing thin-film solar modules, applying solar panel edge treatment, or removing Low-E coatings, TOPAZ LD is your tool of choice for consistent performance and cost-effective operation.

Flexible Application – from PV to Automotive

PV Module Edge Deletion

Reliable and precise ablation of conductive layers at the module edges to prevent corrosion and electrical shorts – critical for the long-term stability and efficiency of solar panels.

Architectural Glass Processing

High-throughput ablation of transparent conductive oxides (TCOs) like ITO or FTO for smart-glass or switching applications.

Automotive Glazing

Clean and selective removal of Low-E coatings to define transmission zones for antennas and mobile signal penetration.

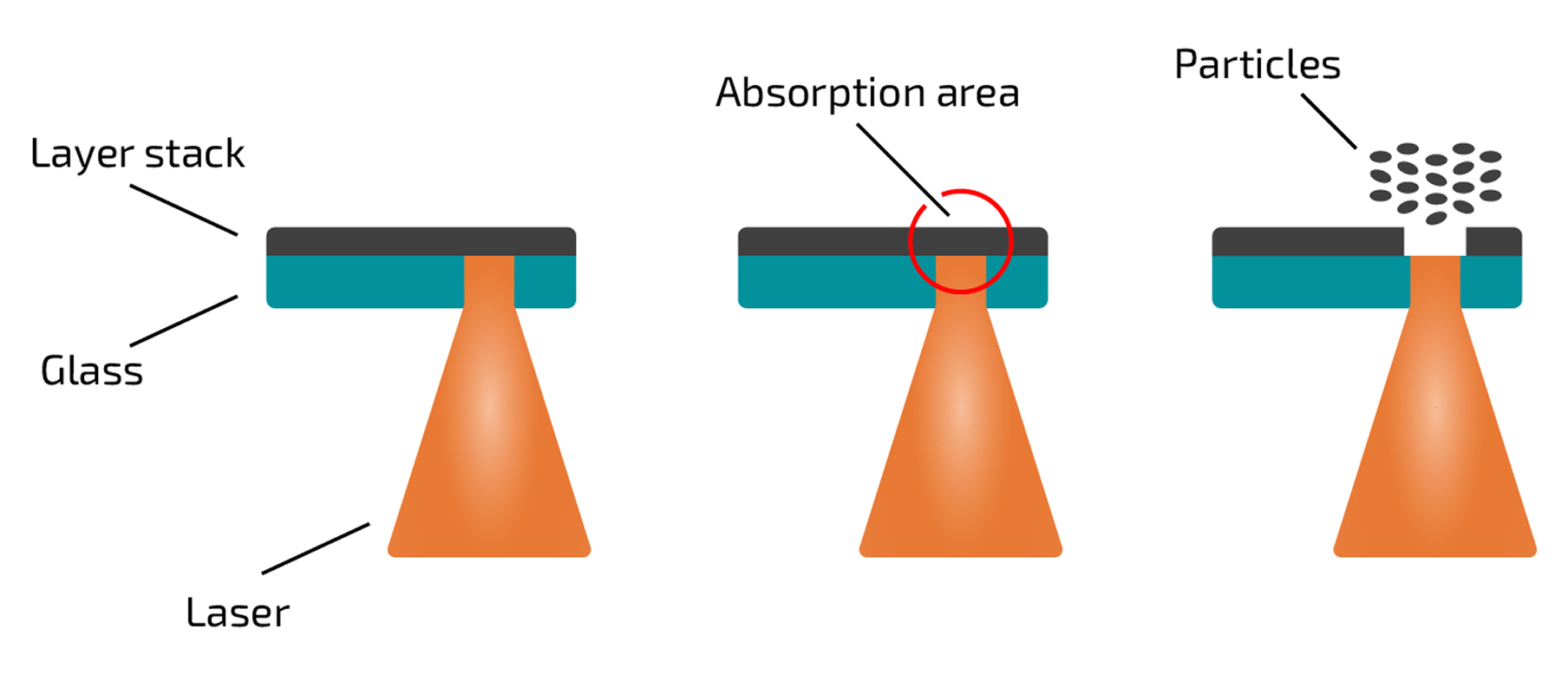

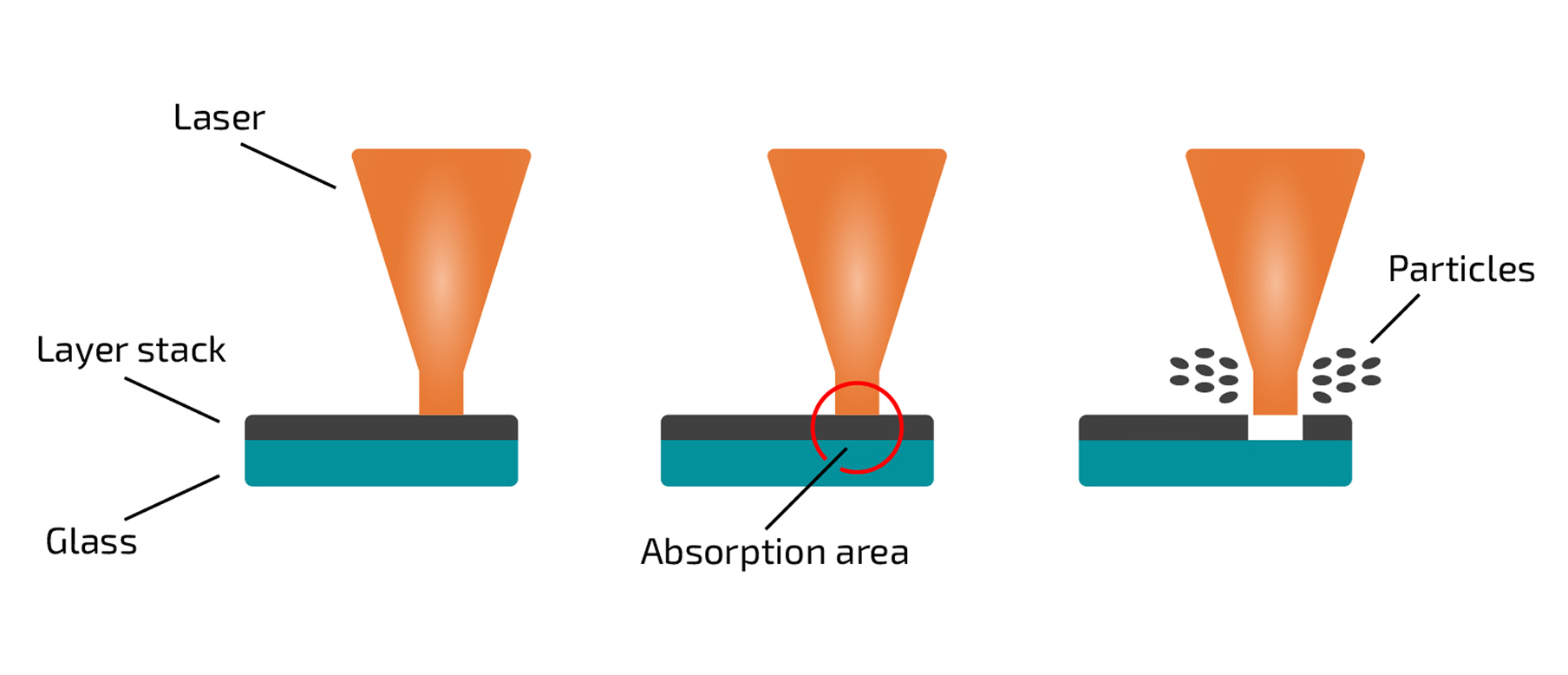

How Laser Deletion Works

TOPAZ LD uses a glass-side infrared laser (1030 nm), optimized for precision laser cleaning for PV and other coated glass substrates:

- The laser pulse energy is absorbed at the interface between the glass and its coating.

- This energy vaporizes the material at the boundary layer.

- A plasma cloud forms and lifts off the entire coating.

Compared to film-side processing, this method provides more uniform material removal, free from recondensation of ablation products or energy losses due to scattering.

Why Laser Over Conventional Methods?

Compared to sandblasting or mechanical grinding, the laser-based patterning offers numerous advantages:

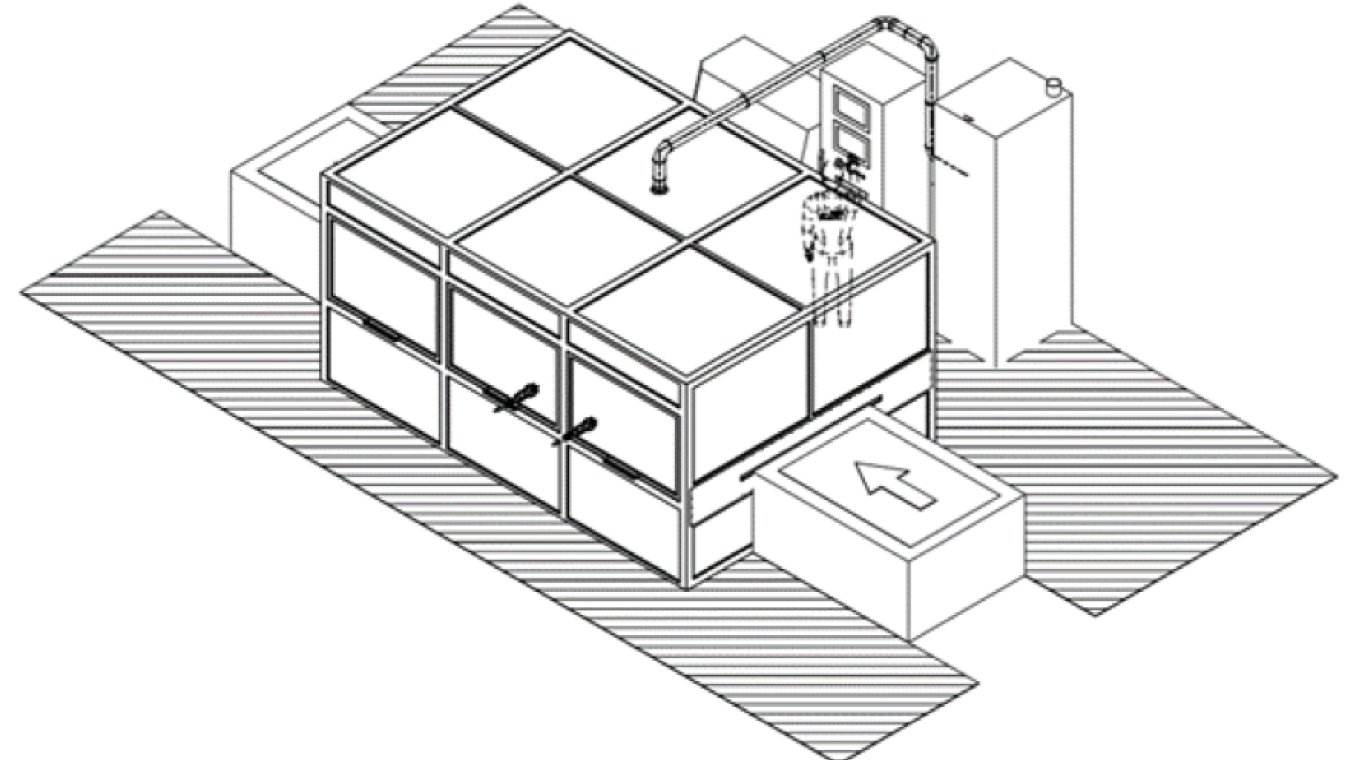

TOPAZ LD: Engineering Excellence in Every Detail

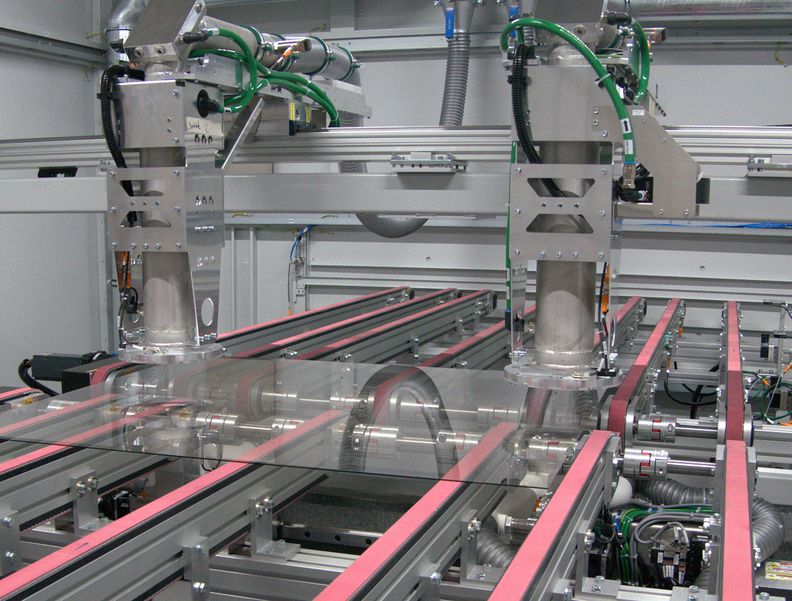

Conveyor System

- Designed to meet the needs of glass transport during laser edge deletion

- Eliminates need for expensive linear grippers

- Delivers both cost-efficiency and high uptime

Granite Base

- Ensures long-term mechanical and thermal stability

- Suppresses vibrations for consistent precision

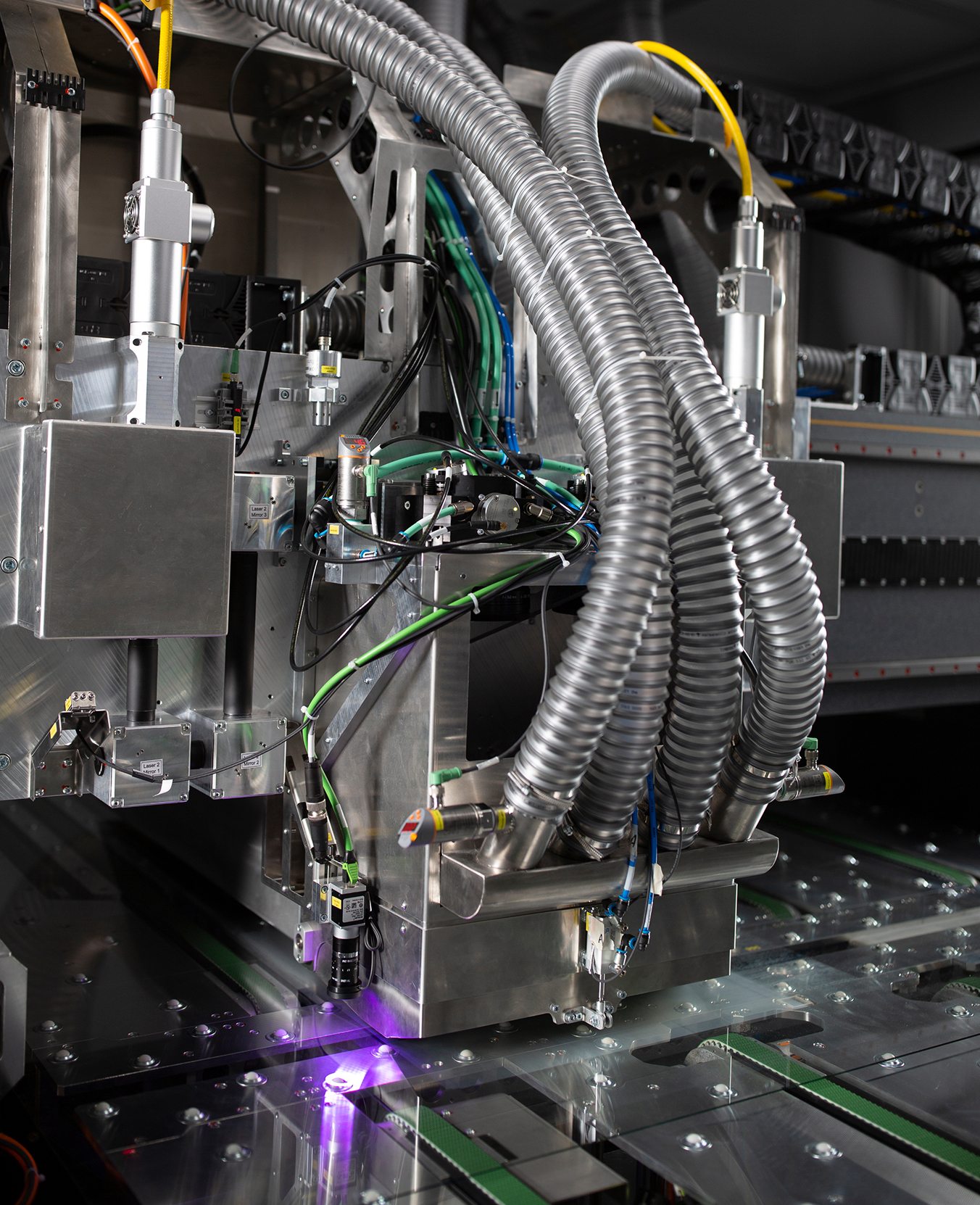

Process Head

- Available with up to two heads per machine

- Built-in 2D marking-on-the-fly scanner for unmatched speed

- Includes camera-based edge detection for ultra-precise tracking

- Modular and low-maintenance, with direct fiber laser connection

Material Compatibility and Use Cases

PV Modules

Edge deletion for thin-film solar technologies:

- CdTe laser edge deletion

- Perovskite

- CIGS

Architectural Glass

Removal of TCOs such as:

- Indium Tin Oxide (ITO)

- Fluorine-doped Tin Oxide (FTO)

Automotive Glass

Targeted removal of Low-E coatings

Defines RF transmission zones using a dry, clean and laser-based method

System Specifications

| Category | Feature | Specification |

|---|---|---|

| System Size & Weight | Dimensions (W × D × H) | Depending on glass size, standard approx. 6200 mm × 3200 mm × 2600 mm |

| Weight | Depending on configuration, standard below 10,000 kg | |

| Axes & Motion | Processing Area | Full glass size processed in 80 mm wide increments across the total glass width. |

| Feed Rate | Up to 1000 mm/s | |

| Acceleration | Up to 10 m/s² | |

| Positioning Accuracy | +/- 300 µm | |

| Software & Operation | HMI | Touchscreen-based user interface |

| Process Layout | Simple recipe configuration, fully customizable layouts | |

| Camera Vision | Intelligent recognition of fiducials and glass edges |

FAQ – Laser Edge Deletion with the TOPAZ LD

Laser edge deletion removes functional layers at the module’s edge to protect against corrosion and shorts.

It ensures long-term performance and stability by eliminating edge-related failure mechanisms.

The laser process is contact-free, more accurate, cleaner, and dramatically reduces wear and waste.

Our system is compatible with CdTe, Perovskite, and CIGS thin-film modules.