Creating Unique, Long-Lasting, Machine-Readable Markings

Common applications of tire sidewall laser marking are the engraving of serial numbers, DOT date codes, logos, and 2D codes in the tire factory. However, there are many other ways to reduce complexity in the tire life cycle with laser marking, e.g. for producing prototype designs for tire development or reducing stock keeping units (SKUs) in the warehouse.

The non-contact laser process enables the production of sharp engravings by selectively removing rubber from the tire sidewall. There are very few restrictions on the design and appearance of the engravings, so that fonts, geometries, structure and engraving depths can be chosen almost at will.

Laser engravings can be edited, added or disabled directly in the tire factory at any time. This allows maximum flexibility in production and reduces dependency on various mold manufacturers. Moreover, the resource-intensive and error-prone process with slug inserts can be eliminated.

In general, the combined marking of several engravings in one process vastly reduces the costs per engraving. Furthermore, our T-Mark system offers the possibility to visually check and document the laser engraved markings.

A New Level of Flexibility in Tire Production

Laser Tire Marking increases the flexibility of tire production by shifting part of the tire sidewall marking further downstream after quality control, tire finishing operations or even to the warehouse. The number of SKUs can be reduced significantly, helping to bring down working capital. The optical appearance of the tire is improved and a new level of flexibility in variant production can be achieved.

Improved Quality and Better Safety

Today, tire marking with tin slug inserts or labels is an expensive manual process leaving room for even more expensive errors: missing or wrong sidewall information can result in costly recalls. Also, manual replacement of slug inserts in a hot and open curing press exposes operators to safety risks.

In contrast, laser marking enables non-contact, flexible, precisely controlled and fully automatic engraving of sidewalls – making Industry 4.0 reality.

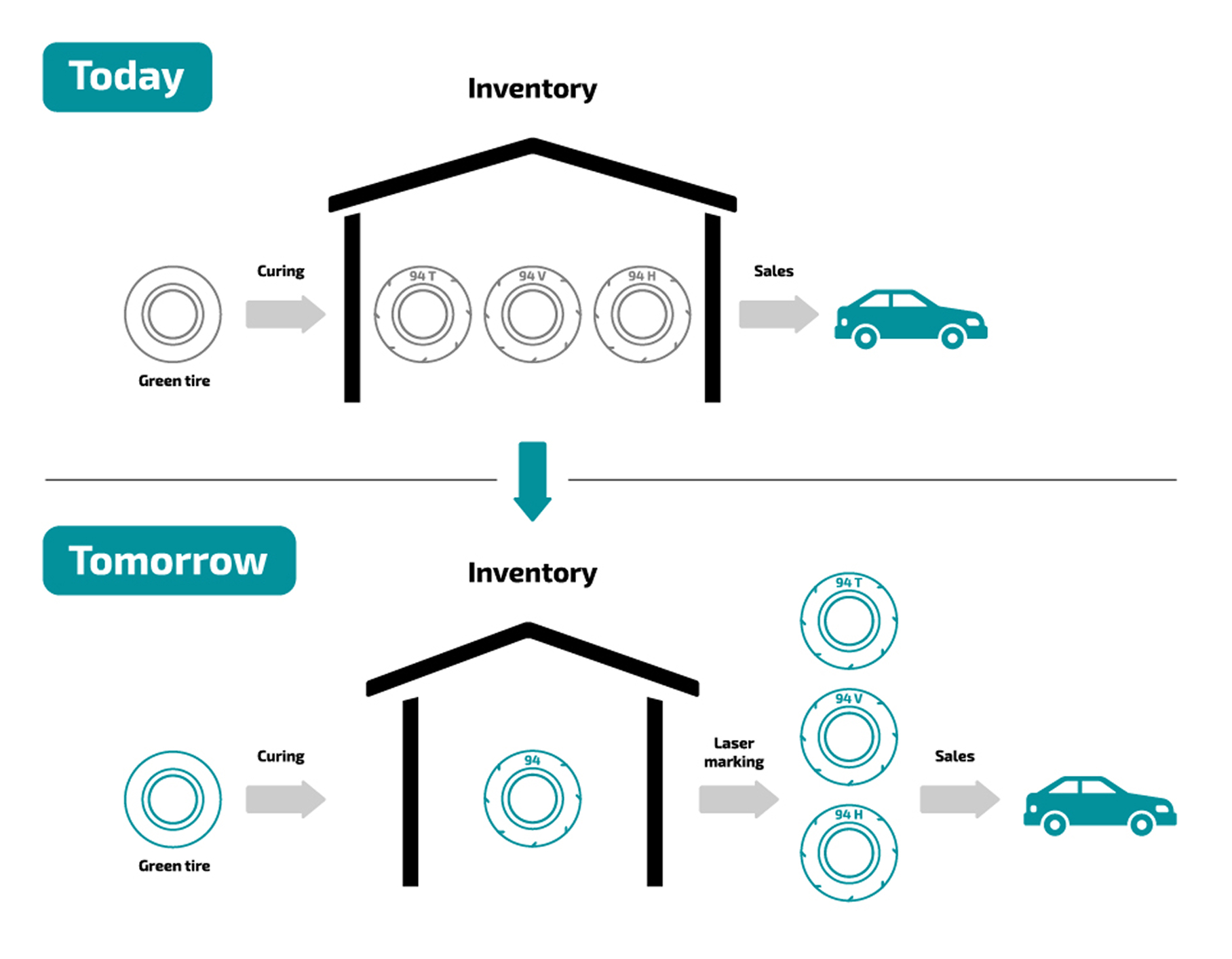

Cutting Down the Number of SKUs to Be Stocked

More and more tire sizes for a constantly growing number of vehicles are driving the increase in the number of SKUs in tire production today. At the same time, both OE and aftermarkets are relentlessly demanding fast delivery of any product anywhere. To meet this requirement, tire makers stock an astonishing 20 % of their revenue in warehouses, tying up billions of cash in inventory.

However, there is an opportunity to drive down inventory levels by downstream customization of tires: The number of green tire types is considerably lower than the actual number of SKU created from these. This is because the same green tire may be used for an OE tire with a special logo as well as its aftermarket version, it may be destined to a specific geography requiring yet another symbol, or it will receive different load and speed indices.

The traditional way of molding all this information on the sidewalls during curing requires tire makers to decide before production where the tire will be sold to – often weeks or months ahead of the time when demand is clear. As a result, and in order to be prepared for every scenario, tire makers stock more tires than needed.

Laser Marking Is Flexible and Reduces Complexity

Using flexible laser marking technology allows to customize a tire platform from one green tire into different SKUs after the curing process. To achieve this, laser marking can be done either after curing in the tire factory, in the warehouse as soon as an order is received for a specific derivative of an SKU, or in both areas to maximize the effect. Such a paradigm shift in manufacturing and warehousing could potentially reduce inventory levels by double-digits and free up significant cash on tire manufacturers' balance sheets.

Typical application examples for platform downstreaming are:

- Product variant symbols (seal, silent, RFID)

- National legal markings ("CCC" or Maple Leaf)

- OE markings (such as the BMW star, "AO" for Audi, etc.)

- Load and speed indices

- Labelling to prevent grey imports

Total Tire Traceability with 2D Codes

Another key application for laser engraving of tires is traceability by QR or datamatrix codes. Using our high-contrast SCANNECT technology, each sidewall can be marked with a permanent and unique, machine readable 2D code within seconds. Key benefits of 2D code marking of tire sidewalls:

- Full traceability

- Lower cost per tire than any competing identifier (labels, RFID)

- Very simple implementation without re-engineering of existing tires

- Automated and controlled process

- Standard approved by leading OEMs

- Codes are readable by selected commercial vision systems and smartphones

- Digital Product Passport (DPP)-ready for digitalization of tires for future use in the EU

Fully Automatic Week Code Engraving

Already today more than 100 million tires carry a laser engraved DOT week code. Replacing the manual exchange of slugs in the curing press has many significant advantages are:

- Lower variable cost per tire

- Improved press uptime

- Elimination of safety hazards for in-press work

- Elimination of human error and costly recalls

- Combination with other marking operations (2D codes, logos and more)

FAQ: Laser Tire Marking with 4JET T-Mark Technology

Laser marking uses a focused beam of light (typically from a fiber or CO2 laser) to modify the surface of the rubber. The laser energy causes localized heating, which results in so-called ablation. The laser removes a thin layer of material and engraves the desired marking on the tire sidewall. In our system “T-Mark” (short for Tire marking) the CO2 laser is controlled by a software that defines the movement of mirrors of a galvanometer scanner in order to move a very small laser spot over the surface of the tire to create the logos, text or matrix codes. The removed rubber is extracted by a suction system and separated from the exhaust air stream via a filter.

Not at all. The heat input from the laser is locally confined to the immediate vicinity of the laser spot and penetrates only a few micrometers into the surrounding rubber. The ablation produces round, soft contours without creating notches. However, it is important to detect or prevent any malfunction of the laser or beam guidance system and to automatically verify the correct processing of the tire after marking. Our T-Mark systems are therefore designed with redundancy and use monitored beam guidance components. In addition, the T-Mark features an automatic inline inspection that evaluates the markin

Laser Tire Marking refers to the non-contact engraving of tire sidewalls using laser radiation. These markings may include serial numbers, DOT codes, logos, or 2D codes. Our technology is widely used in tire manufacturing facilities to create unique, permanent, and machine-readable markings.

Laser marking provides non-contact, permanent, and highly precise engravings directly on the tire sidewall. It replaces manual, error-prone slug insert processes with a fully automated and digitized alternative. This allows for unprecedented flexibility in production, traceability, SKU reduction, and customization – directly supporting modern Industry 4.0 manufacturing paradigms.

Our laser systems support an extensive range of font types, symbols, geometries, and engraving depths. The engraved content can be changed, added, or removed at any time – perfect for agile and highly dynamic production setups.

Yes, virtually all tire types – including passenger car, truck, off-road, and specialty tires – can be laser marked. We offer dedicated T-Mark variants for both PCR (Passenger Car Radial) and TBR (Truck and Bus Radial) tires. The system supports tire outer diameters from 350 mm to 1,300 mm and tire widths from 80 mm to 520 mm, covering a wide range of common tire dimensions. With the manual T-Mark Compact system almost all tire sizes can be engraved. Our systems accommodate various rubber compounds and sidewall geometries. The process is non-destructive and does not affect tire performance, structural integrity, or homologation.

Our T-Mark typically allows marking areas up to 100 mm × 50 mm.

Yes – when properly engineered and integrated, laser tire marking is a safe and highly controlled process. Our systems are fully enclosed, operator-free, and built in accordance with the European Machinery Directive. They comply with Laser Class 1 standards, which means the laser radiation is safely contained and cannot harm the user under normal operation. This makes them inherently safer for high-volume tire production environments.

Laser systems can pose serious risks to the eyes and skin, especially due to the invisible and high-energy radiation used in industrial marking processes. Inadequately shielded optics or poorly maintained equipment – common in low-cost systems – may allow dangerous exposure. We address these challenges through a comprehensive risk analysis, system design aligned to Performance Level standards, and fail-safe concepts that cover malfunctions, maintenance work, and emergency conditions. All systems include monitored safety interlocks, laser-safe enclosures, and active laser control logic. As a result, we ensure that not only routine operations, but also service and fault scenarios are fully protected.

Yes. We hold multiple international patents related to laser tire marking, including technologies for 2D code generation and marking strategies. These patents safeguard unique process innovations and help protect customer investments.

Yes. The laser marking of DOT codes is legally permitted and fully compliant with both U.S. Department of Transportation (DOT) regulations (49 CFR Part 574) and the UNECE Regulation No. 30, as published in EU Document 42008X0730(01). More than 25 million tires per year are already marked with DOT week codes using our T-Mark systems. These engravings are recognized by regulators and leading OEMs as equivalent to traditional molded characters in terms of durability, traceability, and legibility.

In addition, the laser marking process ensures long-term legibility and can be verified by automated vision systems – further enhancing compliance and safety in global markets. The term “moulded” used in Regulation No. 30 is, according to its multilingual interpretations, not limited to mechanical molding but refers more broadly to any permanent and legible integration into the tire material –including high-quality laser engravings.

Absolutely. T-Mark is a digitally controlled system that supports centralized management and full integration into smart factory environments. We are pioneering the digital transformation of tire manufacturing.

Typical applications include adding:

- Product variant symbols (e.g. silent, seal, RFID)

- Regional legal compliance marks (e.g. CCC, Maple Leaf)

- OEM-specific codes (e.g. BMW star, Audi “AO”)

- Load/speed index changes

- Anti-counterfeiting labels to prevent grey imports

Several leading global tire manufacturers use our T-Mark solutions, including those in the top five globally.

While the initial investment in laser marking equipment may be higher than manual methods, the overall TCO is significantly lower (~0.07 €/tire*). Benefits include reduced labor costs, elimination of inserts, improved press uptime, minimized rework and recall risk, and lower inventory holding costs. The ability to combine multiple markings in a single process step further enhances ROI. Our customers typically achieve fast payback periods of <18 months.

*cost for 1 marking per tire with T-Mark system

Cycle times depend on the complexity and size of the engraving but are typically between 10 to 30 seconds per tire. Our high-speed galvo scanners and multi-axis handling systems ensure optimal throughput, making the system compatible with high-volume production environments.

By shifting the marking step to after vulcanization, a single green tire can be customized into various SKUs. This dramatically reduces the number of stocked variants, lowering inventory costs and tied-up capital. Our T-Mark solution seamlessly integrates this capability at the end-of-line or even in the warehouse.

Manual insert changes in hot curing presses pose significant safety risks. Our laser systems operate without any physical contact and are fully automated, enhancing operator safety and removing the need for in-press intervention.

Yes. With our downstream marking approach, tires can be finalized late in the process based on actual customer orders. This not only reduces SKUs and storage overhead, but also enables variant-specific branding.

Our SCANNECT technology allows permanent, machine-readable 2D codes to be engraved on every tire. These enable full traceability throughout the product’s lifecycle, and support Digital Product Passport (DPP) compliance for future EU requirements.

Yes. Our SCANNECT codes are engineered for high contrast and durability, and can be read with both industrial vision systems and smartphones – supporting both in-plant and in-field use cases.

Laser engraving offers superior durability compared to labels and a much lower cost per tire compared to RFID tags. It’s also easier to implement without modifying the tire structure. Our SCANNECT solution is a proven, cost-effective technology.

Replacing manual slug changes with laser-engraved DOT codes reduces labor cost, improves press uptime, eliminates safety hazards, and allows error-free marking. With 4JET, these markings can also be combined with 2D codes and branding in one step.