TOPAZ 3D – Laser Patterning of Curved Glass

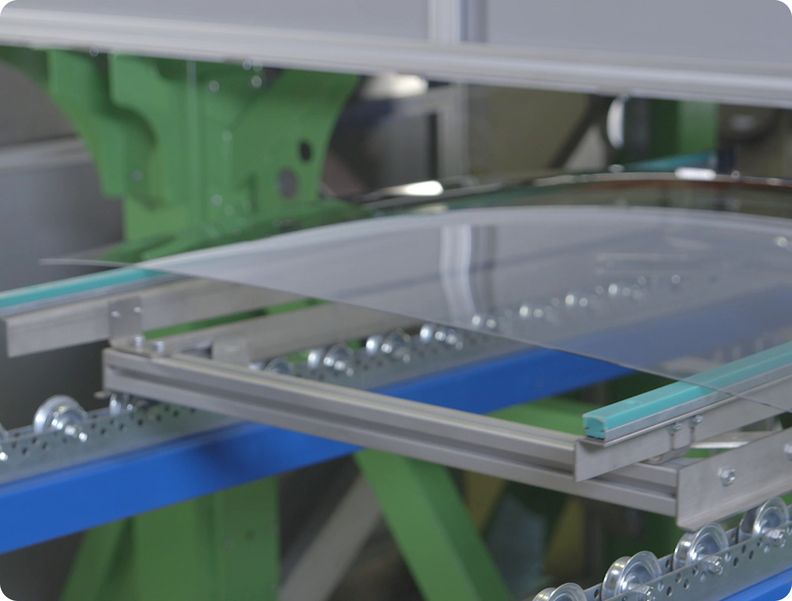

The TOPAZ 3D is our market-leading solution for laser patterning of curved glass in the automotive industry.

Specifically engineered for coated and heated windshields, the system delivers high-speed, high-precision patterning of complex 3D geometries. Supporting over 500,000 windshields per year, it achieves cycle times below 30 seconds – making it ideal for inline OEM production.

Whether you need laser structuring of curved glass, laser processing of coated windshields, or fine-feature RF filter patterning on automotive glass, the TOPAZ 3D sets new standards in performance and flexibility.

Applications in Automotive Glass Laser Processing

The TOPAZ 3D is the benchmark in automotive glass laser processing, capable of:

- Laser ablation on bent glass with perfect surface tracking

- Laser structuring of curved glass for sensor and camera windows

- Windshield laser patterning for integrated antenna and heater structures

- Laser processing of coated windshields without damaging functional layers

- Laser ablation for HUD glass with ultra-high optical quality

- RF filter patterning on automotive glass with invisible line resolution

- Display and cockpit glass with complex 3D curvatures

Technology Advantage – True 3D Patterning on Bent Glass

Unlike traditional step-and-repeat methods, our TOPAZ 3D uses stationary laser heads and dynamic beam deflection across all axes. This allows full-surface 3D glass laser ablation in one continuous motion – enabling:

- Perfect pattern accuracy across large, curved areas

- Shorter cycle times

- No mechanical repositioning or staging

- Homogeneous pattern quality even on sharply curved surfaces

Technical Highlights

Technical Details:

| Feature | Advantage |

|---|---|

| Remote 3D scanning | Ultra-short cycle times |

| Large scan field (1.2 x 1.2 m²) | Covers full windshield processing areas in a single scan |

| Optional dual-laser configuration | Extended scan field up to 1.2 x 1.6 m² and further cycle time reduction |

| Dynamic 3D laser focus control | Accurate patterning on curved, bent surfaces |

| High-resolution patterning | Fine lines with variable width – invisible to the human eye |

| Camera-based fiducial referencing | High alignment accuracy despite shifting placement |

| OEM-ready design | Engineered for 24/7 high-volume automotive environments |

Ready to Elevate Your Windshield Production?

Looking for a solution for laser patterning of curved glass that meets OEM standards for speed, accuracy and scalability?

Talk to us today and discover how the TOPAZ 3D can revolutionize your automotive glass laser processing.