JETLASER Integration

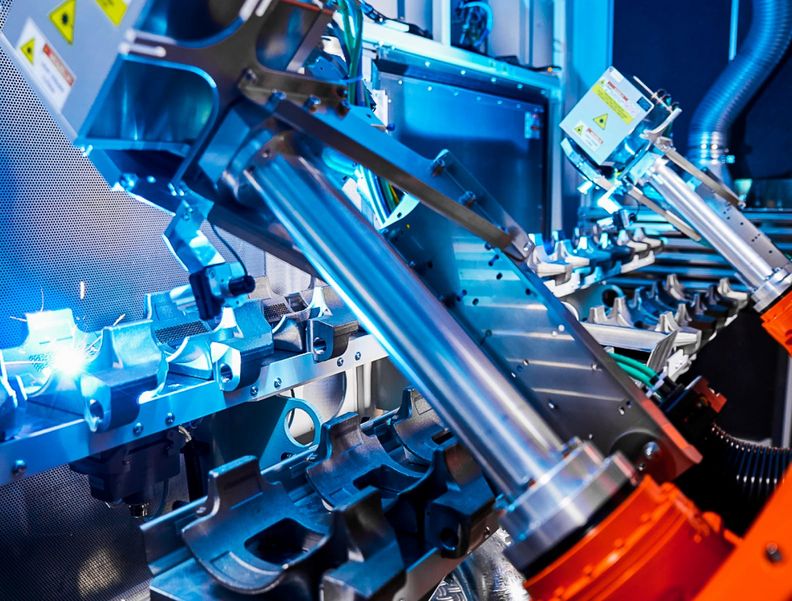

Laser Process Head for Cleaning, Pretreatment and Paint Removal Systems

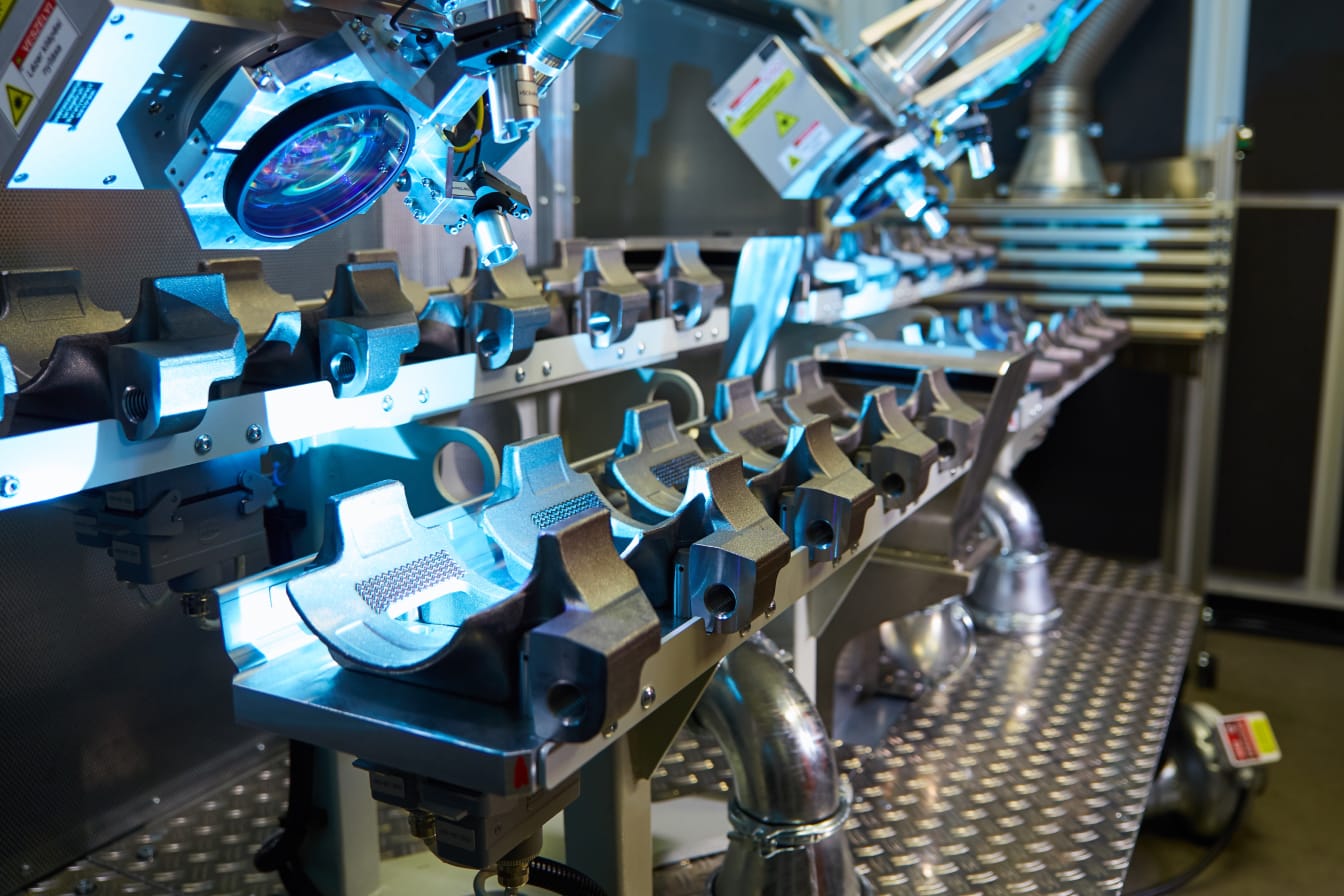

Whether laser cleaning, paint stripping, surface preparation or other laser machining processes: The trend towards the tool “laser” is undeniable. Lasers work dry, contact-free, precisely and deliver reproducible results.

For several decades, our physicists, engineers and other developers have been working on laser-based surface processing.

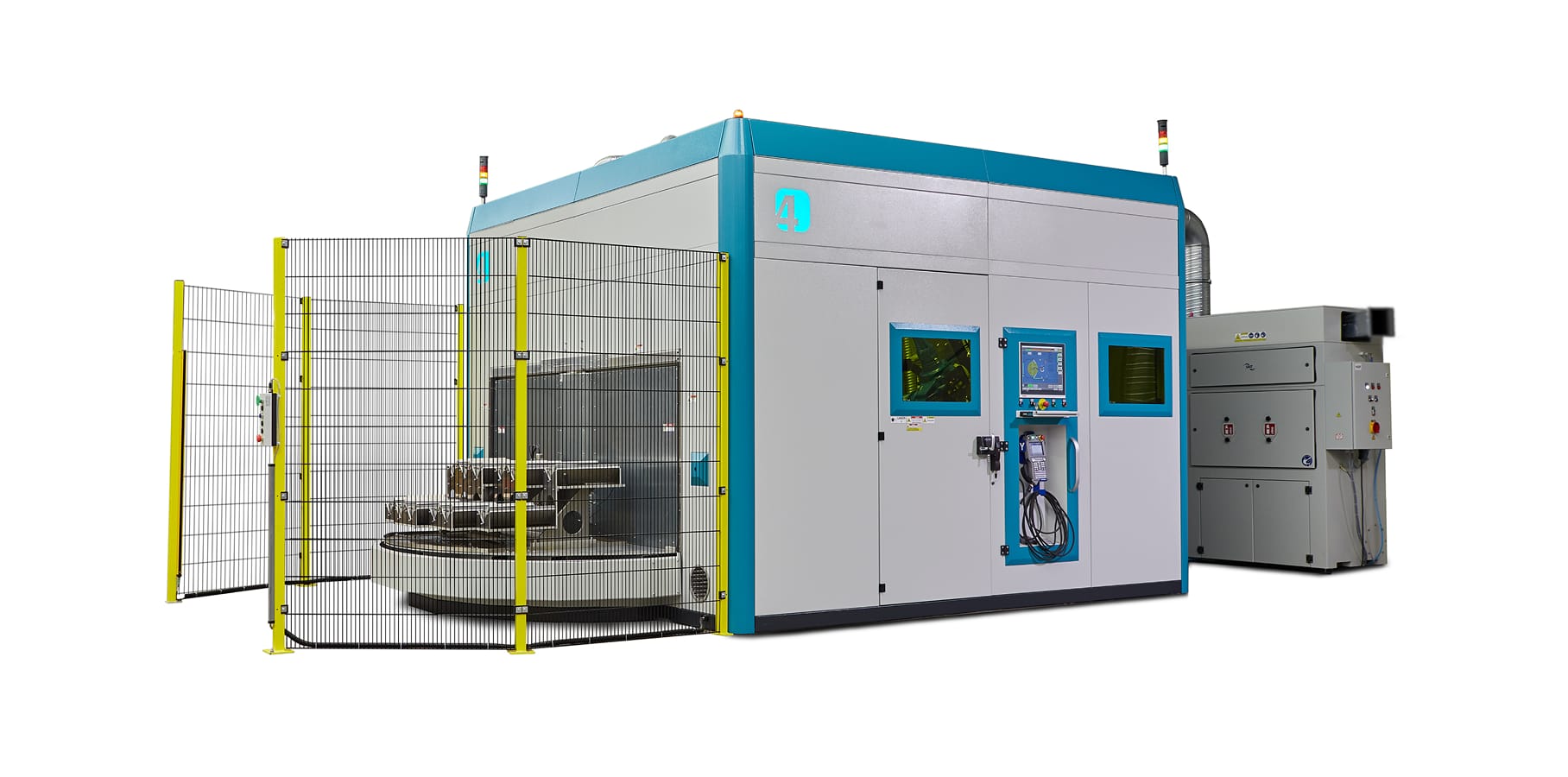

Now we are making laser technology accessible to other machine builders and offering JETLASER Integration, a solution package for system integrators and special machine builders.

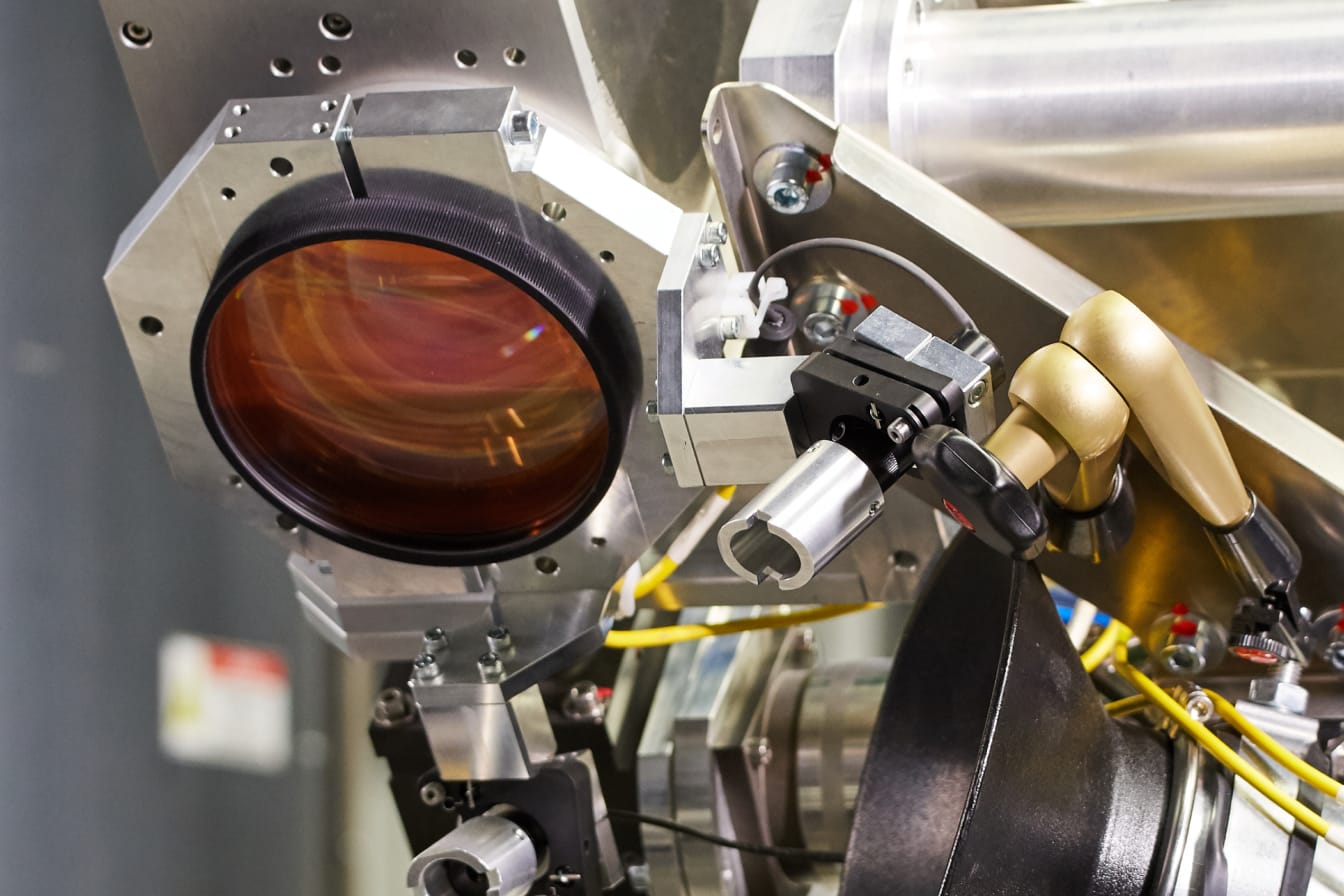

Modularity for Better Economics

Our integration modules allow machine builders to offer powerful and customized laser process solutions. We take care of the development of the specific laser processes, as well as the configuration of suitable laser sources and optics. In a package with our powerful software, sophisticated, customer-specific solutions can be realized.

This modularity enables shorter delivery times, reduces technical risk and improves cost-effectiveness. In addition, our customers benefit from our extensive application experience and two decades of experience in building industrial laser machines.

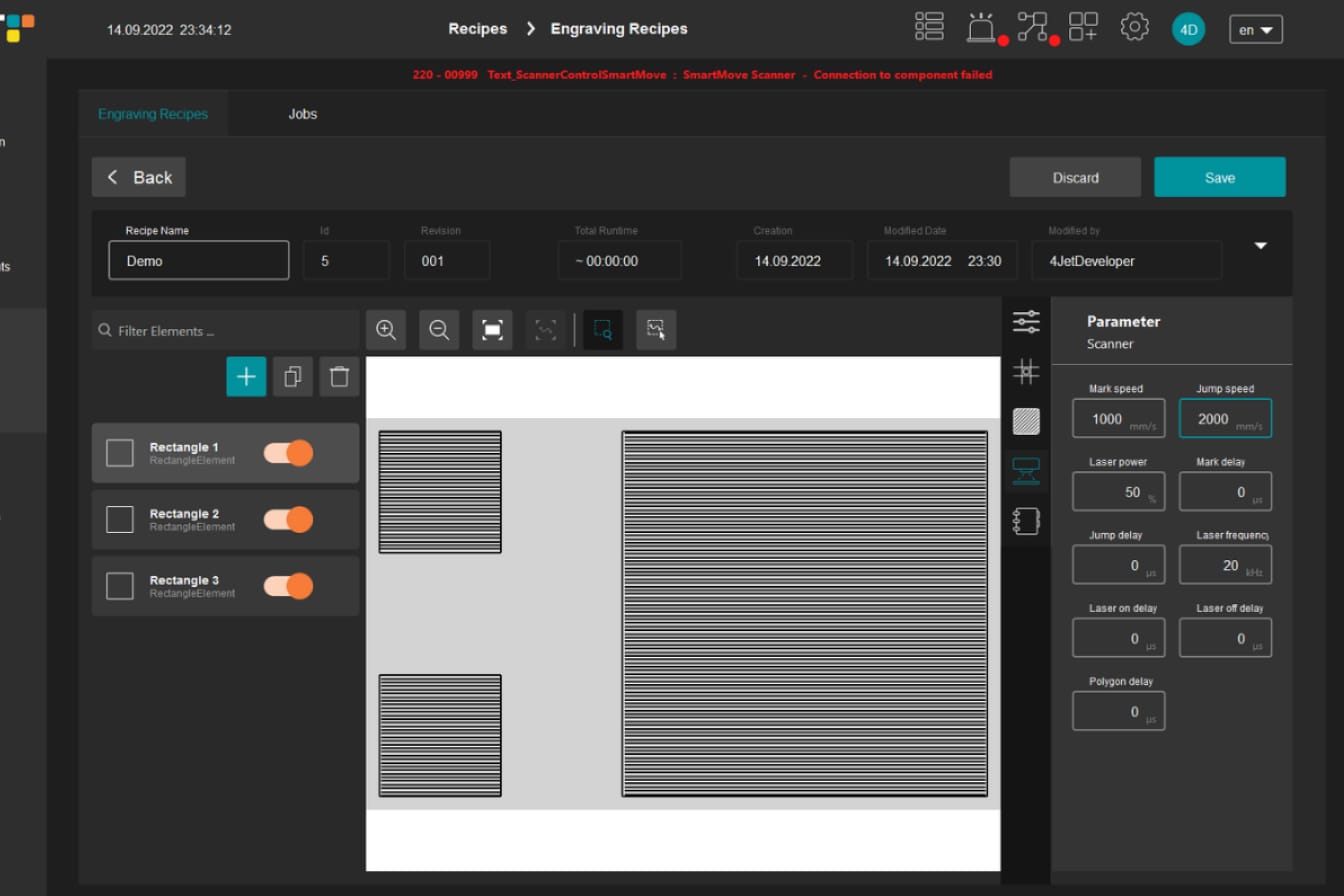

User-friendly Framework and clean Interface

The brain of our JETLASER integration modules is a powerful software engine based on our new Core4 framework. With just a few mouse clicks, the parameters for laser scan heads and laser source control can be set.

A detailed interface documentation for the software connection facilitates the integration into your machine solution.

JETLASER Integration – Key benefits of our laser process head

Our Laser Head for Cleaning and Paint Stripping – Proven in 24/7 Use

Largely maintenance-free solid-state and fiber lasers, optics and control hardware of our modules have been proven in hundreds of demanding installations around the world.

In addition, we offer 24/7 service around the world.

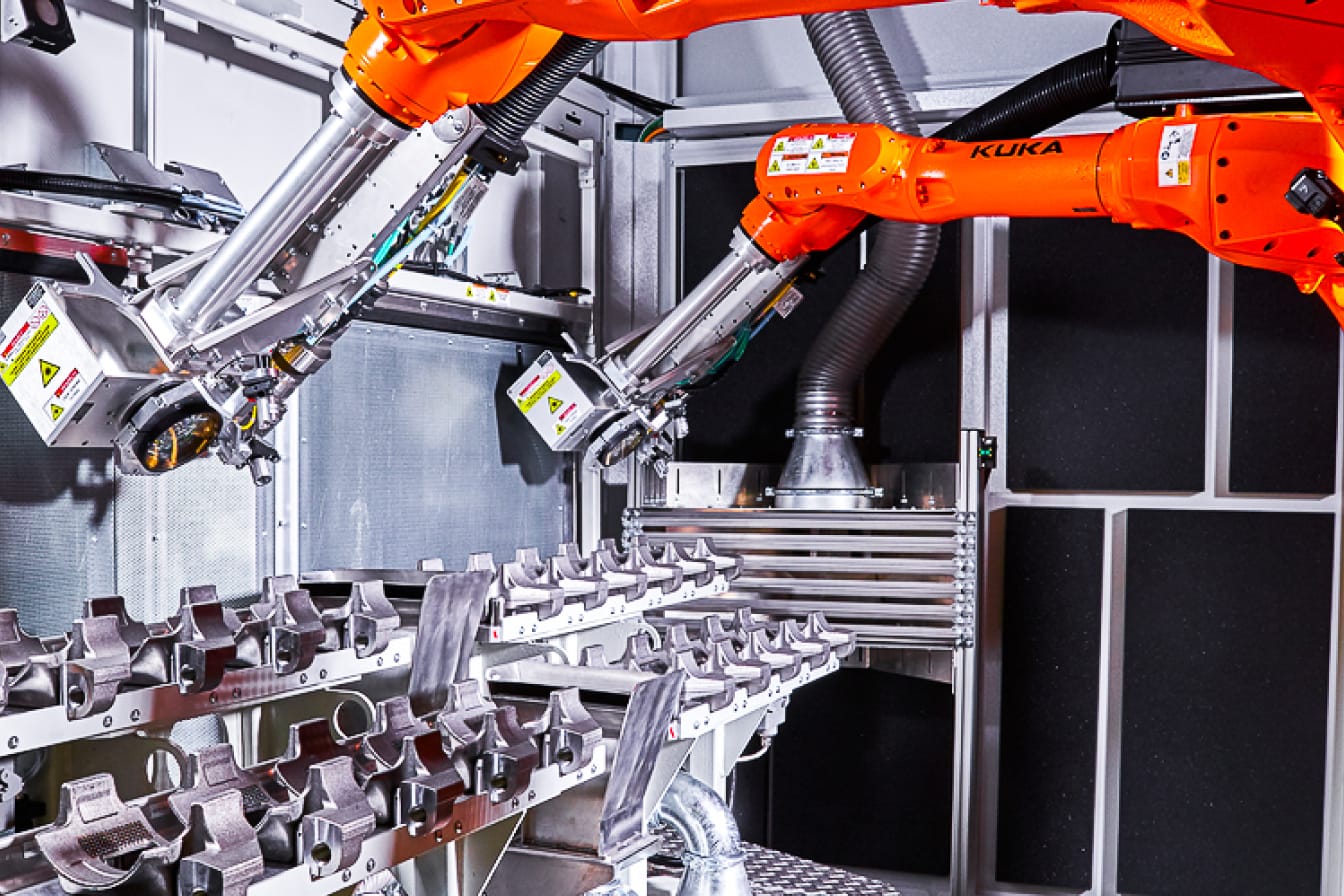

Looking for Integrator?

We develop our own complete machines for our most important markets, but we serve the multitude of possible applications and components in other industries through partnerships.

We work together with specialists for specific automation solutions – from the compact workcell to the complex line solution with several robots.