Augmented Reality

Laser Precision for the Next Generation of AR Glasses and Waveguides

AR optics demand the highest precision in glass cutting, drilling, and surface structuring. We deliver scalable laser solutions that enable the production of lightweight, high-performance optical components for consumer and enterprise AR/VR devices.

Why Laser Processing for AR?

As augmented and mixed reality (AR/MR) technologies mature, the demand for ultra-precise processing of optical glass components intensifies. Core elements such as waveguides, beam combiners, prisms, and protective lenses require micron-level accuracy, optical-grade surface quality, and zero mechanical stress – standards that mechanical methods struggle to meet.

We provide scalable, laser-based manufacturing solutions tailored for cutting, drilling, and surface microstructuring of AR-grade glass – including ultra-thin, chemically strengthened substrates. Our non-contact, cleanroom-compatible systems are designed for precision and yield – supporting both prototyping and high-volume production.

From lightweight consumer AR glasses to enterprise-grade optical modules, we enable consistent, high-throughput processing of advanced optics with unmatched precision and process control.

Key Technical Features for AR Glass Processing:

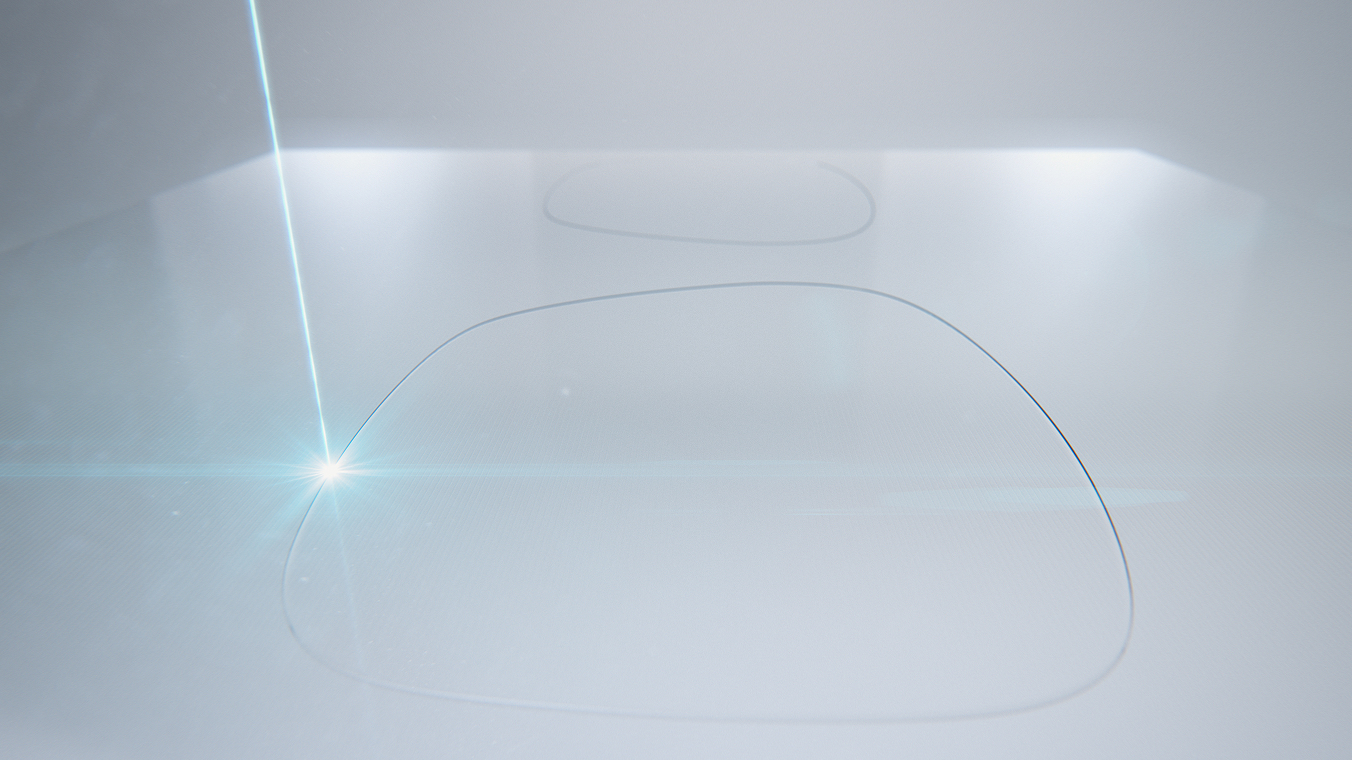

Cutting of Waveguides and Cover Glasses

Applications:

- Precision shaping of planar waveguides, combiners, prisms, and covers

- Separation of ultra-thin, high-index and chemically strengthened glass

- Ideal for curved or planar AR/MR optical components

4JET Technology Fit:

- Bessel beam and enhanced nanoPerforation (EnP) cutting for micro-crack-free, optical-grade edges

4JET Solution:

- High-strength, debris-free edge quality with scalable throughput and complex shape capability

4JET Platforms:

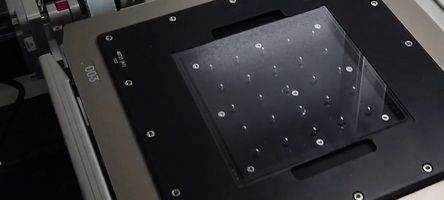

Drilling and Microstructuring for Optics Integration

Applications:

- Micro-apertures, alignment holes, edge notches for optical assembly

- Mounting or coupling features for integrated lenses and electronics

4JET Technology Fit:

- USP laser micromachining for ultra-fine holes and repeatable feature formation

4JET Solution:

- Sub-50 μm features, high aspect ratios, zero thermal or mechanical stress

4JET Platforms:

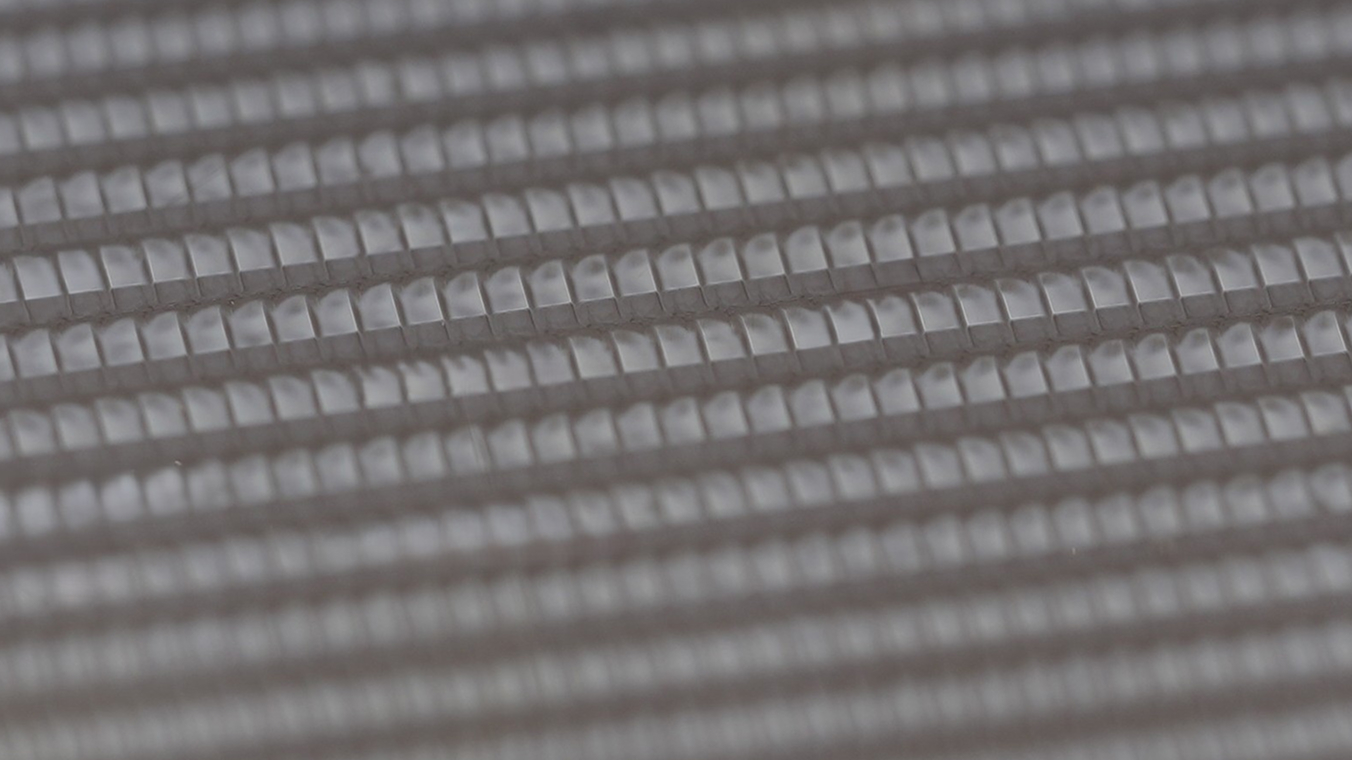

Surface Texturing & Light Management Structures

Applications:

- Light extraction patterns, collimators, gratings, and custom optical geometries

- Tailored surface features for improved AR light management

4JET Technology Fit:

- Grayscale laser texturing and diffractive pattern generation at sub-micron precision

4JET Solution:

- Optical-grade topography for enhanced image clarity and coupling efficiency

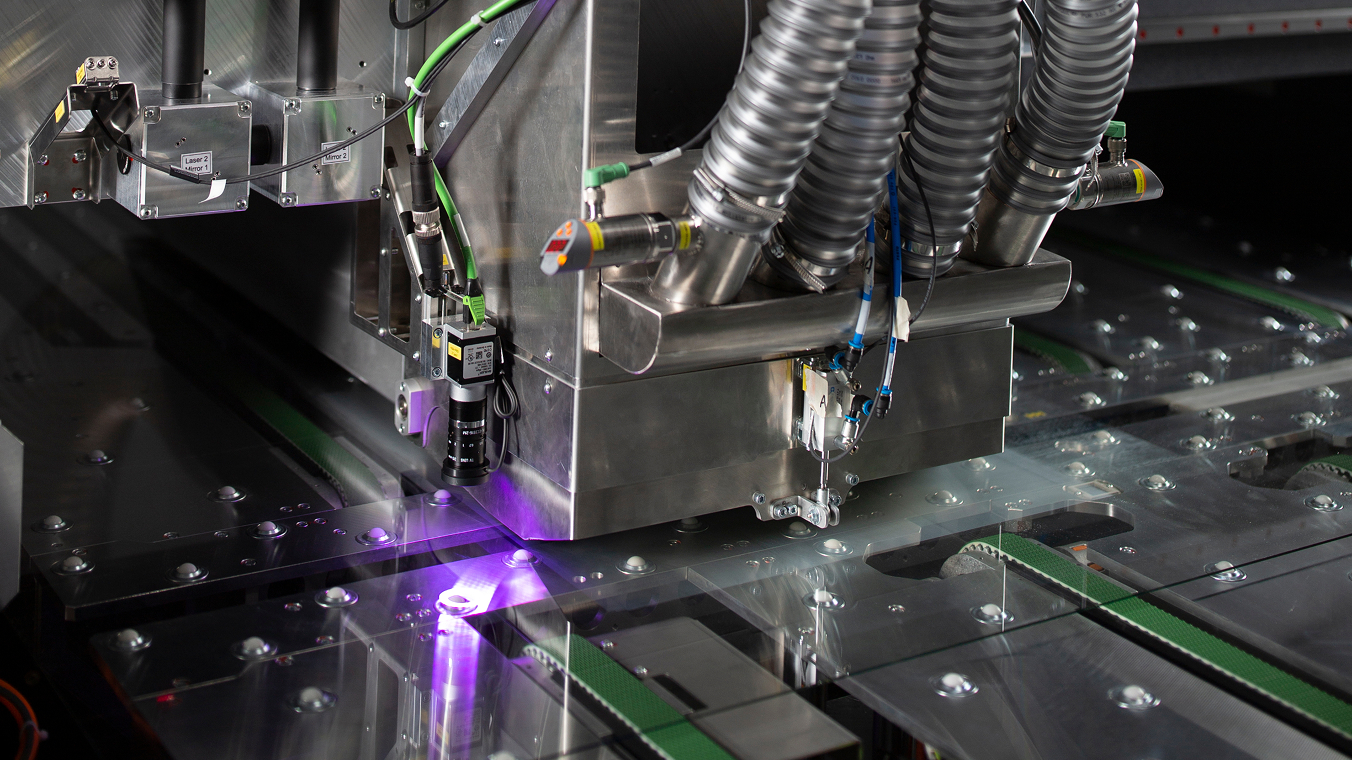

Coating Ablation for Optical Tuning

Applications:

- Patterning or removal of ITO, AR, or polarization coatings

- Defining optical windows, bonding zones, or electrical paths

4JET Technology Fit:

- Maskless, high-resolution ablation with minimal layer damage

4JET Solution:

- Real-time vision-aligned laser processing of thin-film stacks – enabling safe, selective ablation with minimal thermal impact

Why 4JET?

Tailored platforms for AR/VR optics production – from R&D to high-volume

Industry-leading edge strength and cleanliness via EnP and Bessel beam technology

Cleanroom-ready laser processing with zero-contact methodologies

IP-protected solutions trusted in consumer electronics and precision optics industries

Let’s Build the Future of AR Optics Together

Contact our experts about how we can bring precision, performance, and scalability to your AR/VR production line.

Enabling Capabilities Across All AR Glass Applications

Delivering precision laser processes to AR optics requires more than just beam quality. We provide a powerful ecosystem of enabling capabilities that ensure yield, speed, and scalability from prototyping to high-volume manufacturing – all backed by robust software, automation, and support infrastructure.

Core4 Software Platform Global Services & Support Automation Integration

Core4 Software Platform

The foundation of every 4JET AR solution is Core4 — our modular control software for laser, scanner, vision, and automation.

- Optimized UI/UX for AR cleanroom environments and intuitive operator guidance

- AI-enhanced machine vision for waveguide alignment, edge detection, and defect classification

- Supports PLC sequencing, recipe control, and full system integration

- Maintained by a 20+ member in-house dev team for scale and lifecycle support

Let’s Build the Future of AR Optics Together

Talk to our experts about how we can bring precision, performance, and scalability to your AR/VR production line.