Aviation

Laser Applications Transforming Aviation Sustainability

The global commercial aviation industry faces mounting pressure to reduce its environmental impact, as it currently accounts for more than 2% of man-made CO2 emissions. With over 30,000 aircraft in service worldwide, the sector must rely on incremental advancements to move toward greener operations. Among these, laser technology has emerged as a powerful ally in optimizing aircraft efficiency and sustainability by delivering practical, incremental improvements that can be widely adopted today – both in the air and on the ground – while disruptive solutions such as Sustainable Aviation Fuel (SAF) are still likely to be decades away from development.

Surface Functionalization Using Laser

Up to 30 Million Tons Less CO2 – Thanks to Laser-Engineered Sharkskin Surfaces

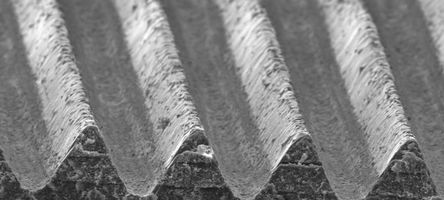

One of the most promising uses of lasers in aviation is surface functionalization. By applying laser-based texturing techniques, we can create biomimetic surfaces (sharkskin-like) on an aircraft. These innovative textures reduce aerodynamic drag, resulting in up to 3% lower fuel consumption on lang-haul flights. Even such modest improvements translate into significant reductions of over 30 Mio Tons of CO2 every year.

LEAF Technology: Aerodynamic Innovation for Aviation

LEAF (Laser Enhanced Air Flow) technology leverages the shark skin-effect to revolutionize surface functionalization across industries like aviation, renewable energy, and maritime transport. Drawing inspiration from the microscopic riblets on shark skin that reduce drag, LEAF uses a laser interference process to engineer precise micro- and nanostructures onto material surfaces, reducing friction by up to 10% and optimizing flow dynamics. This innovative method uses the interaction of two laser beams to create large-area flexible surface patterns and is therefore much faster and robust compared to classical laser writing technologies.

LEAF can be applied to already certified materials, ensuring long-lasting effects without compromising existing standards. With two laser units capable of treating up to 1 m2 per minute, LEAF technology enhances energy efficiency and supports sustainability efforts. It delivers operational benefits to high-tech industries that strive for greater performance and a lower environmental impact.

Laser Paint Stripping & Laser Coating Removal

Faster, Safer, and Greener: How Laser Transforms Aircraft Maintenance

Laser paint stripping is revolutionizing aviation maintenance by offering a cleaner, faster, and greener alternative to traditional paint removal methods. Conventional techniques for removing paint and coatings from aircraft components typically involve harsh chemicals or abrasive processes that can damage sensitive materials and generate hazardous waste. Unlike chemical strippers or abrasive blasting, laser systems use focused beams of light to precisely remove paint and coatings without compromising the integrity of composite materials. This not only reduces the time necessary for aircraft maintenance but also minimizes ecological impact.

Laser Removal Processes as Key Enablers for Greener Aviation

One of the standout benefits of laser paint stripping is its positive impact on maintenance turnaround time. The aircraft can be returned to service more quickly because laser systems are highly efficient and can even locally target the areas that require treatment, minimizing downtime. Additionally, this method eliminates the need for large quantities of hazardous chemicals, leading to less toxic waste and a safer working environment for maintenance crews. Overall, laser paint stripping supports the aviation industry’s drive toward sustainability by cutting emissions, reducing waste, and improving operational efficiency.

Laser Bonding Preparation

Next-Level Bonding Performance with Laser Surface Treatment

In aerospace engineering, bonding reliability and repeatability are absolutely critical. As the aerospace industry increasingly shifts from metal to hybrid materials, adhesive bonding is becoming ever more important — conventional joining methods such as welding or soldering no longer work in these applications. Whether for structural components or lightweight assemblies, the quality of surface preparation directly impacts the strength and durability of these adhesive joints.

Traditional methods such as chemical etching or mechanical abrasion often introduce variability, debris, or waste. In contrast, laser bonding preparation offers a clean, precise, and highly reproducible solution – especially for advanced composite materials like carbon fiber reinforced polymers (CFRP).

Clean and Consistent Bonding Surfaces for Aviation Applications

Specialized pulsed cleaning lasers are used for precise surface treatment. Guided by high-precision deflection units, the laser beam is guided across the target area, enabling both selective and uniform processing. This technique effectively removes contaminants, oxides, and residues from the substrate and activates the surface through an increased wettability. Depending on the application, the laser parameters can be finely tuned to achieve the desired result. In this way, surfaces can be cleaned gently without altering the underlying material. Alternatively, the process can be adjusted so that the laser radiation generates a microstructure on the surface – enhancing the effective bonding area and improving adhesive strength through additional mechanical interlocking. As a pretreatment for the subsequent welding process, all types of contamination, as well as undefined oxide layers, can be removed touchless. This enables homogeneous weld seams.

Finaly the result of laser cleaning is a dry, clean, residue-free, and sterile surface, optimally prepared for bonding or welding – without the use of chemicals or abrasive media. Laser-based surface preparation ensures every joint meets the rigorous demands of flight safety, structural performance, and long-term reliability.