Automotive

Driving Innovation in Automotive with Laser Processing

The automotive world is changing rapidly, and so are the demands placed on car manufacturers. Digitalization, connectivity, autonomous driving, electric drives and re-invention of the manufacturing process represent only a fraction of the challenges facing the industry. With cutting-edge laser technology, we meet the evolving demands of modern manufacturing.

Laser Precision for Automotive Excellence

From Surface Preparation to Glass Cutting – Laser Technology that Drives Innovation

Our laser solutions are used in various steps in automotive manufacturing, ranging from cleaning of surfaces and patterning of functional coatings on windshields to precision cutting of interior glass parts.

Reinventing Automotive Manufacturing for a New Era

The automotive industry is undergoing a profound transformation. Electrification drives the need for lightweight designs, pushing the adoption of aluminum and composite materials. At the same time, the growing use of adhesive bonding demands perfectly clean and consistently activated surfaces. Regulatory pressure and sustainability goals further accelerate the shift toward smarter, greener production. Traditional processes can no longer keep pace – manufacturers must rethink their strategies and embrace advanced technologies. Laser-based solutions open new possibilities: precise, contactless, and fully digital, they enable efficient, repeatable surface preparation and integration into Industry 4.0 workflows, setting the stage for the next generation of automotive manufacturing.

Another key trend: the in-car user experience is evolving rapidly. Inspired by the smartphone world, automakers are rethinking interfaces, increasing the use of displays and glass, and demanding flawless surface quality. These changes create new challenges – and opportunities – for innovative manufacturing technologies.

Key Technical Features for Advanced Surface Processing in Automotive Manufacturing

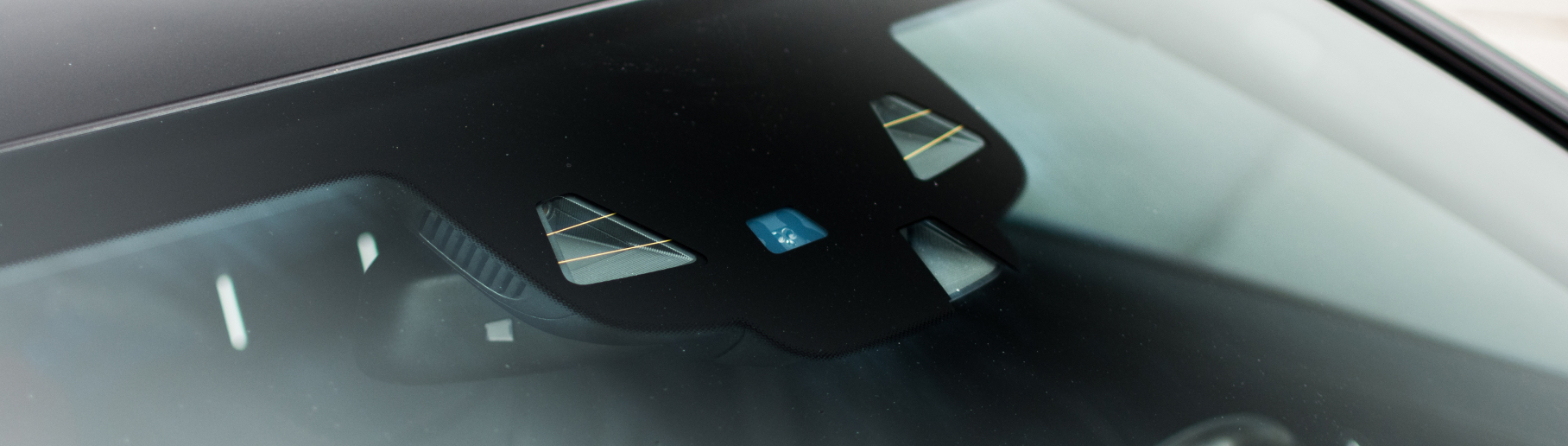

Why Glass Matters in Modern Mobility

Automotive glazing has evolved into a critical enabler of vehicle performance – supporting connectivity, user experience, lightweighting, and safety. With the rise of HUDs, ADAS sensors, and smart surfaces, manufacturers require glass processing technologies that deliver accuracy, durability, and design flexibility.

We provide industry-leading laser solutions for high-speed cutting, selective coating removal, and precision microstructuring. Our systems are scalable for both prototyping and high-volume production, enabling next-gen vehicle platforms that are lighter, smarter, and more integrated.

Key Technical Features for Automotive Glass Processing:

Key Applications & Our Capabilities in Laser Processing of Automotive Glass

Laser Cutting of Automotive Glass Lightweight & Advanced Glazing Selective Coating Ablation Micromachining for Integrated Sensors & Electronics Edge Deletion & Surface Structuring Decorative and Ambient Lighting Panels Non-flat and Inner Contour Cutting

Laser Cutting of Automotive Glass

Use Cases:

- Contour cutting of windshields, sidelites, and backlites

- Shaped cuts for HUD zones, mirror brackets, and sensor apertures

- Supports monolithic, laminated, and coated glass

4JET Technology Fit:

- Bessel beam laser cutting for crack-free edges and high mechanical strength

4JET Solution:

- Precision cutting with low thermal impact scalable from pilot to high-volume lines

4JET Platforms:

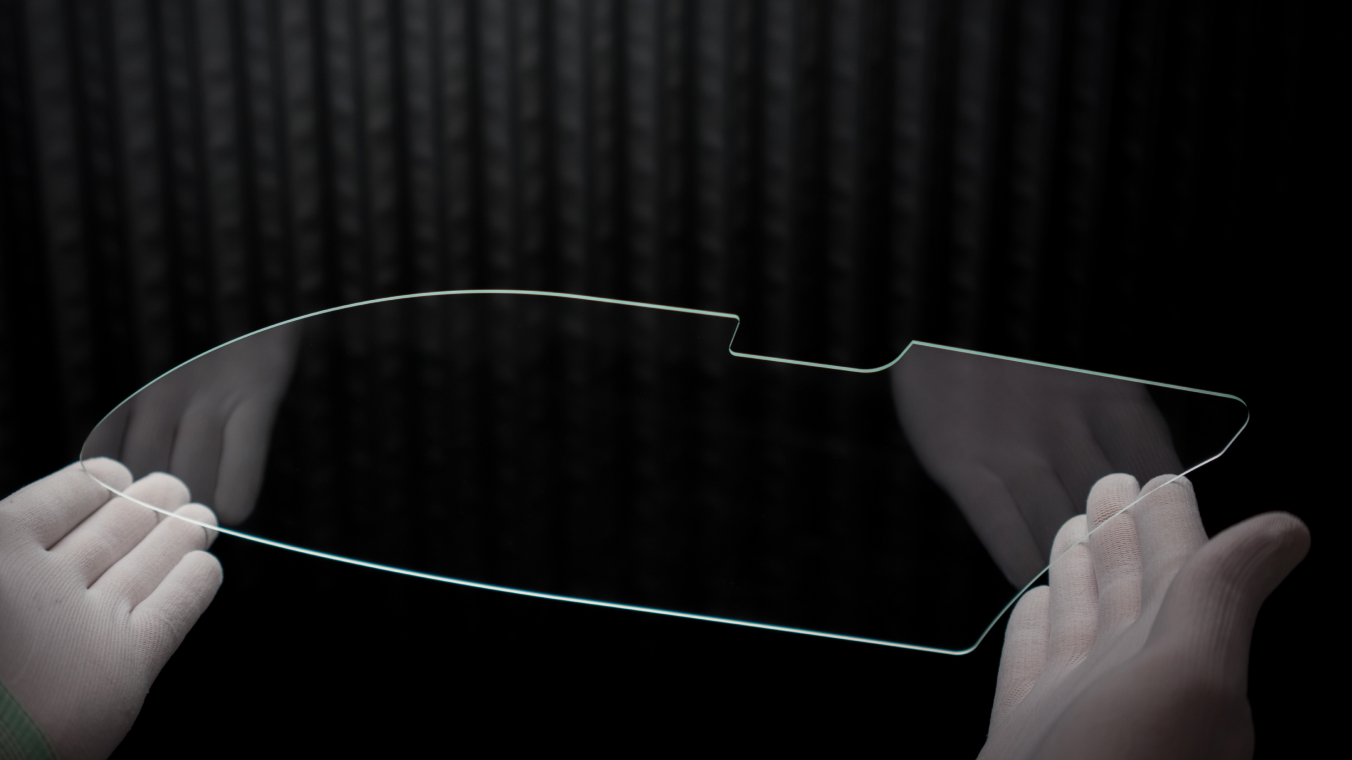

Lightweight & Advanced Glazing

Applications:

- Ultra-thin, curved, and strengthened glass for roofs and displays

- Lightweight backlites and complex 3D shapes for aerodynamic and weight reduction

4JET Technology Fit:

- Contactless cutting and edge structuring with micron-level precision

4JET Solution:

- High-quality, stress-free edges – no mechanical grinding needed

4JET Platforms:

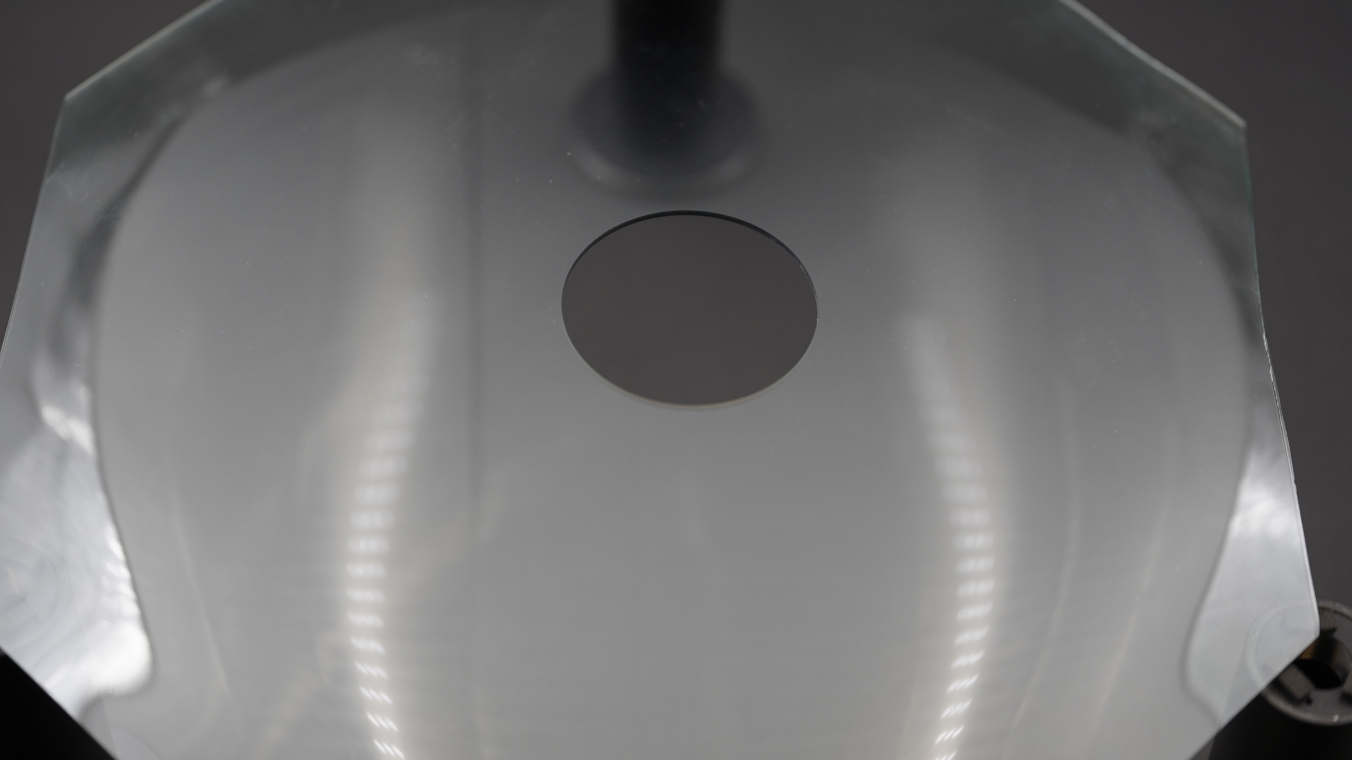

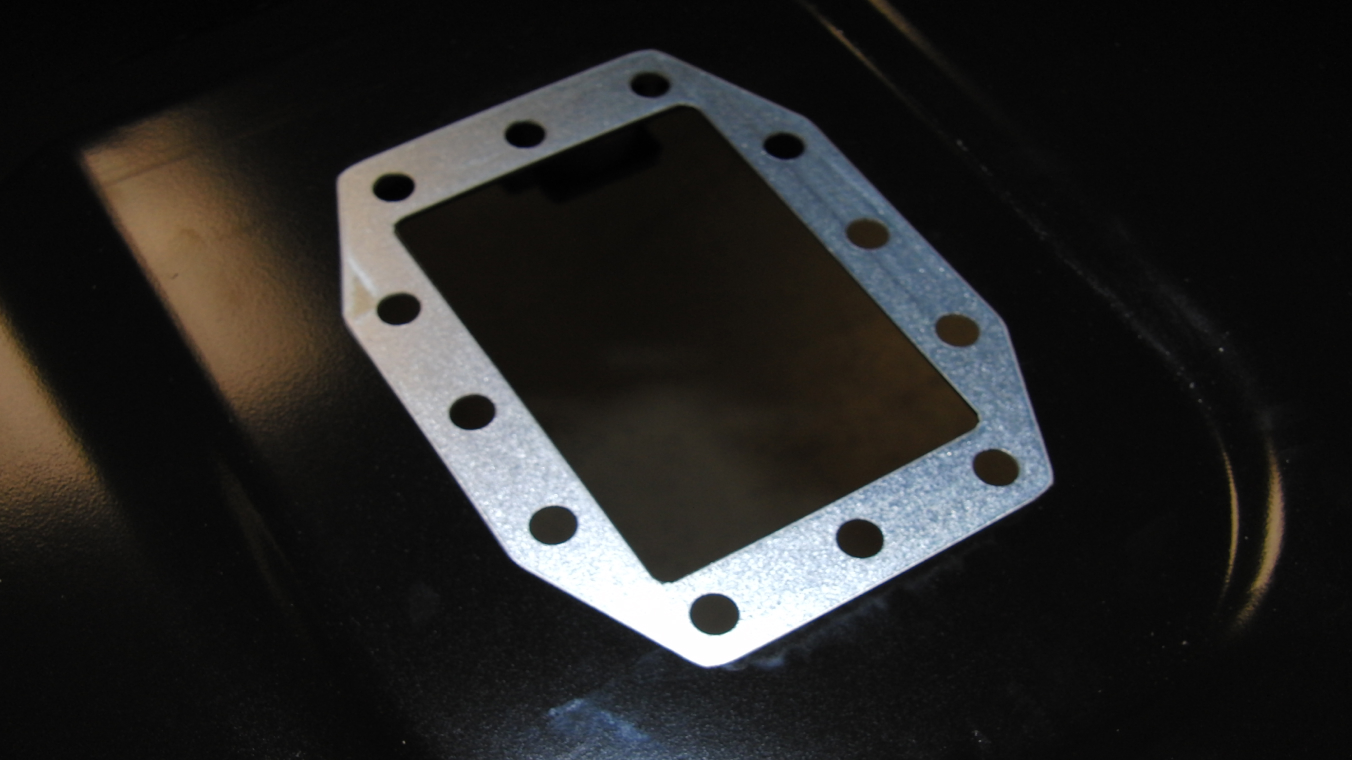

Selective Coating Ablation

Applications:

- Patterning for defrost zones, solar control, or smart glass features

- Removal of ITO, anti-reflective, UV-blocking or hydrophobic layers

4JET Technology Fit:

- Fast, precise laser ablation of multilayer functional coatings without thermal damage

4JET Solution:

- Non-contact, selective patterning with zero substrate damage

4JET Platforms:

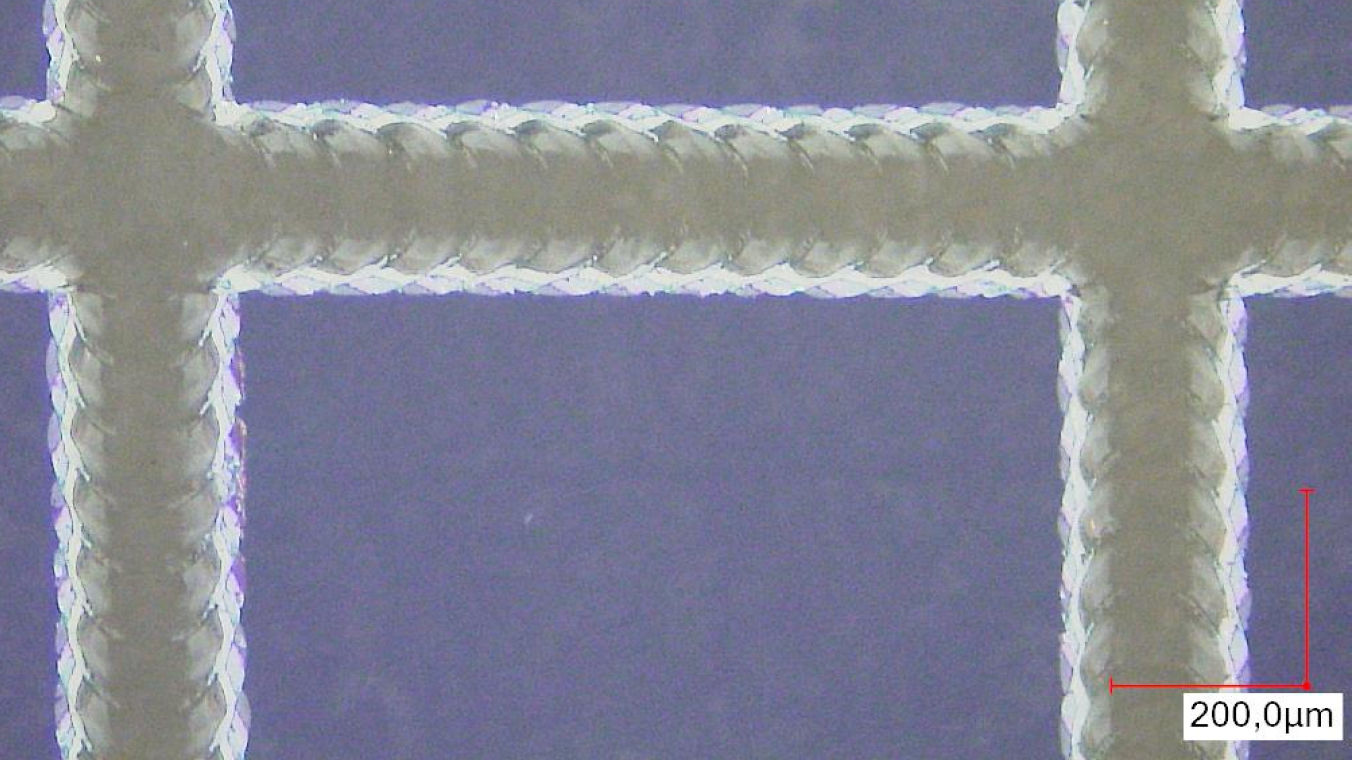

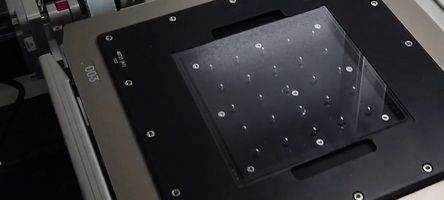

Micromachining for Integrated Sensors & Electronics

Applications:

- Apertures and access zones for LIDAR, antennas, heating, or rain sensors

- Precision drilling and feature shaping on glass substrates

- Drilling and selective coating removal for smart glazing

4JET Technology Fit:

- USP laser micromachining with high repeatability and no cracking

4JET Solution:

- Non-contact laser processing with customizable system architecture – ideal for integrating ADAS, connectivity, and e-mobility functions into automotive glass without cracks or delamination

4JET Platforms:

Edge Deletion & Surface Structuring

Applications:

- Coating removal in bonding areas (PUR adhesive, laminates)

- Surface microtexturing to enhance adhesion or optical performance

4JET Technology Fit:

- Controlled high-speed laser edge deletion with precise zone depth and alignment control

4JET Solution:

- Clean surface prep –no mechanical post-treatment needed

4JET Platforms:

Decorative and Ambient Lighting Panels

Applications:

- Interior glass patterning for ambient light guidance

- Custom branding textures or light-diffusing features

4JET Technology Fit:

- Laser engraving and microstructuring for visual and functional effects

4JET Solution:

- Functional and decorative textures for design-focused interiors

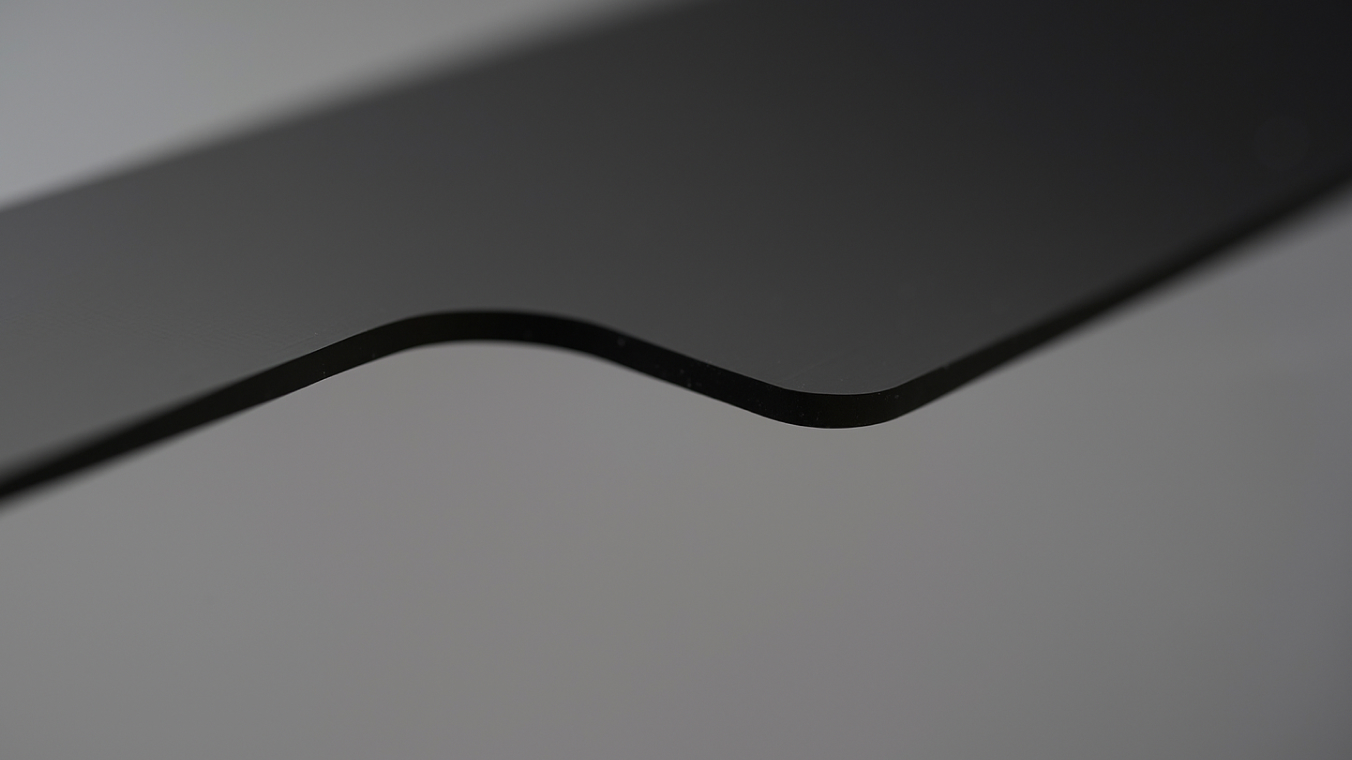

Non-flat and Inner Contour Cutting

Applications:

- Shaped or preformed glass parts (bent, domed, 3D)

- Internal cut-outs or nested geometries

4JET Technology Fit:

- Depth-independent Bessel beam cutting with 3D processing capability

4JET Solution:

- High-precision processing of complex geometries –non-contact, no tool wear

Key Applications & Our Capabilities in Surface Processing for Automotive Manufacturing

Laser Cleaning & Surface Preparation

Applications:

- Pre-treatment before bonding, sealing, or coating

- Removal of residue, release agents or oil

- Cleaning of battery housings and trays in e-mobility

- Cleaning of aluminum parts, or joining areas

- Surface activation for painting and powder coatings

- Surface Texturing

- Weld Cleaning

4JET Technology Fit:

- Controlled laser ablation and microstructuring with high selectivity and surface-friendly energy input

4JET Solution:

- Residue-free, dry cleaning and surface preparation with consistent results — no chemicals, no abrasives, no masking

4JET Platforms:

Coating Removal

Applications:

- Selective coating removal on aluminum, steel components, and composite materials

- Coating removal on EV battery housings, connectors, or structural parts

- Selective stripping of coatings in automated lines

- Stripping of CDC, primer, or adhesives for joining and bonding prep

- Pre-weld and pre-bonding decoating

4JET Technology Fit:

- High-speed laser ablation with selective depth control and minimal thermal input

4JET Solution:

- Precise, contactless removal of coatings without chemicals or tool wear — ideal for sensitive or high-value components

4JET Platforms:

Ready to Redefine Your Manufacturing?

Let’s discuss how our laser solutions can elevate your next vehicle platform.

Enabling Capabilities Across All Automotive Applications

While our solutions for the automotive industry are engineered around precision, repeatability, and industrial scalability, they are enhanced by cross-cutting capabilities that add long-term value, operational reliability, and digital readiness across all applications.

Core4 Software Platform Global Services & Support Automation Integration

Core4 Software Platform

The brain behind every 4JET system: Core4 is our modular, in-house software platform controlling laser, scanner, vision, and automation tasks.

- Intuitive UI/UX for operator efficiency in automotive production lines

- AI-powered vision algorithms for positioning, edge detection, and defect classification

- Fast deployment through tested modules and PLC sequencing

- Supported by a 20+ developer team for rapid customization and lifecycle support

Global Services & Support

We know uptime and service responsiveness are critical in automotive manufacturing.

- Remote diagnostics and software-based troubleshooting

- On-site training, process tuning, and preventative maintenance

- Global field service team with fast-response capabilities across key markets

Ready to Redefine Your Manufacturing?

Let’s discuss how our laser platforms can elevate your next vehicle platform.