Tire Industry

Shaping the Future of Tire Production with High-Performance Laser Systems

Our laser systems deliver next-level flexibility and efficiency for tomorrow’s tire manufacturing

Navigating the Tire Industry’s Toughest Challenges

The tire industry is under immense pressure to stay competitive. Global price competition demands cost efficiency and continuous innovation from technology leaders. Meanwhile, the explosion of product variants – driven by electric vehicles (EVs), larger rim sizes, and specialty tires – is creating unprecedented complexity in production, logistics, and inventory management, with stock-keeping units (SKUs) growing rapidly. Industry 4.0 and AI are accelerating innovation cycles and transforming manufacturing processes at a record pace. Furthermore, sustainability and regulatory compliance are no longer optional – they are strategic imperatives. Success will depend on agility, digitalization, and a relentless focus on efficiency and environmental responsibility.

Laser Precision for the Future of Tire Production

Our advanced laser systems deliver the next level of flexibility and efficiency the tire industry needs. From final finishing to variant creation and full customization, we enable agile, Industry 4.0-ready processes. Sustainable, precise, and cost-effective – our solutions help manufacturers meet regulatory demands while staying ahead in innovation and competitiveness.

Our Laser Systems are the Perfect Tools for Tire Processing

- Tire Rubber Loves Lasers: Tire rubber offers excellent absorption properties for almost all laser wavelengths and features low evaporation energy. Contactless processing is ideal for its flexible, wobbly surfaces and the abrasive and sticky material.

- Fully Automated & Flexible: Adapts to all tire sizes and types with the highest repeatability and consistent quality.

- Efficiency at Its Best: Shortest cycle times, optimized for productivity and total cost of ownership.

- Industry 4.0 and AI Ready: MES integration, a full digital workflow, and inline quality control ensure maximum process reliability while providing valuable product data for your AI strategy.

Key Applications & Our Capabilities

Silent TiresLaser Tire MarkingLaser Tire Mold CleaningTire Inner Liner Laser CleaningLaser Tire Uniformity Correction

Silent Tires

In the innovative LASER-FIT process, a tailor-made acoustic foam is produced directly inside the tire from liquid starting materials. This method eliminates the just-in-sequence complexity, time-consuming logistics, and manual process steps, while also giving the tire manufacturer greater freedom in adapting geometry and volume of the foam. Combined with our Tire Inner Liner Laser Cleaning System (TCS), it eliminates the use of expensive adhesives.

Laser Tire Marking

It increases the flexibility of tire production by shifting part of the tire sidewall marking process further downstream, after quality control and tire finishing operations, or even to the warehouse. The number of stock keeping units (SKU) can be reduced significantly helping to bring down your working capital. It improves the optical appearance of your tires by getting rid of ugly insert marks and minimize cost and complexity of the cumbersome weekly DOT insert exchange process.

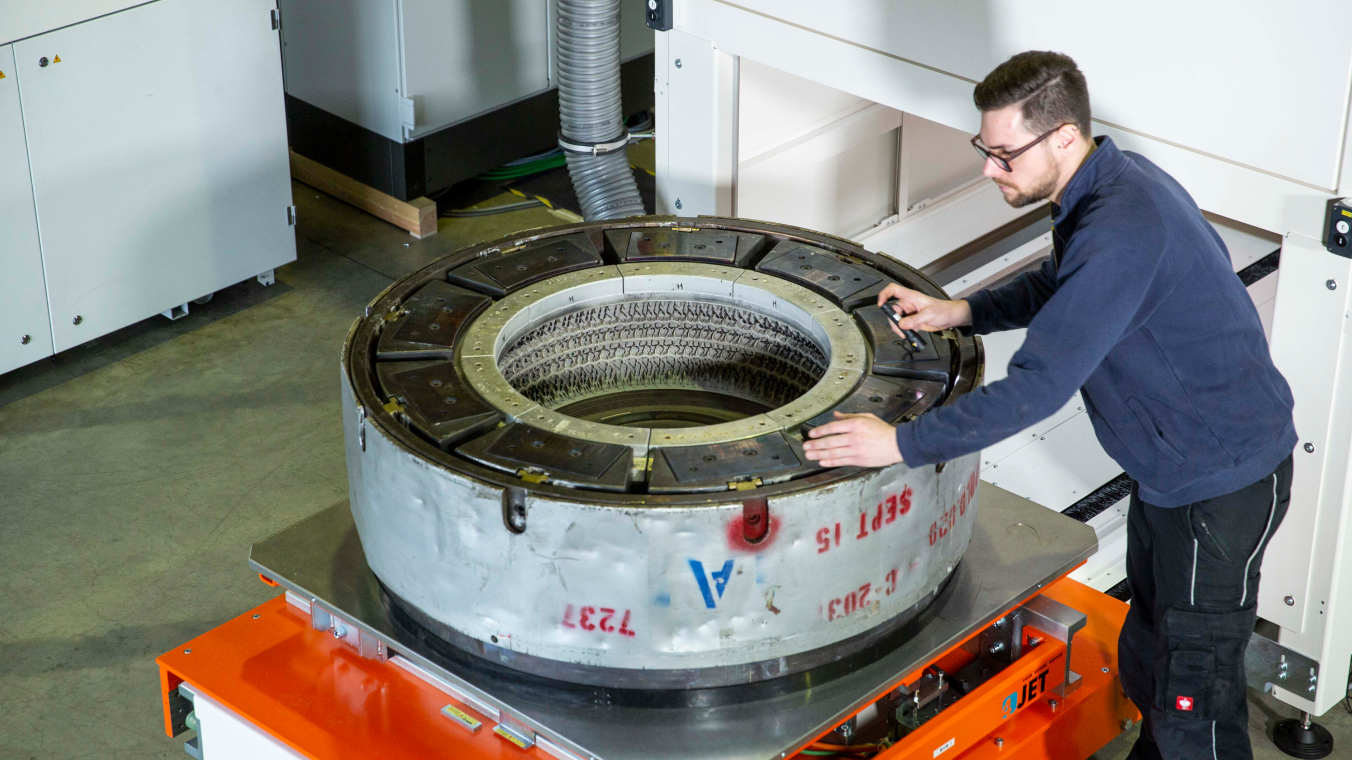

Laser Tire Mold Cleaning

Contactless laser mold cleaning guarantees an always perfect and consistent high-quality appearance of your tires and allows for spring-based venting systems. Make your high-tech tires look “high-tech” and reduce noise emissions as well as carbon footprint in your production.

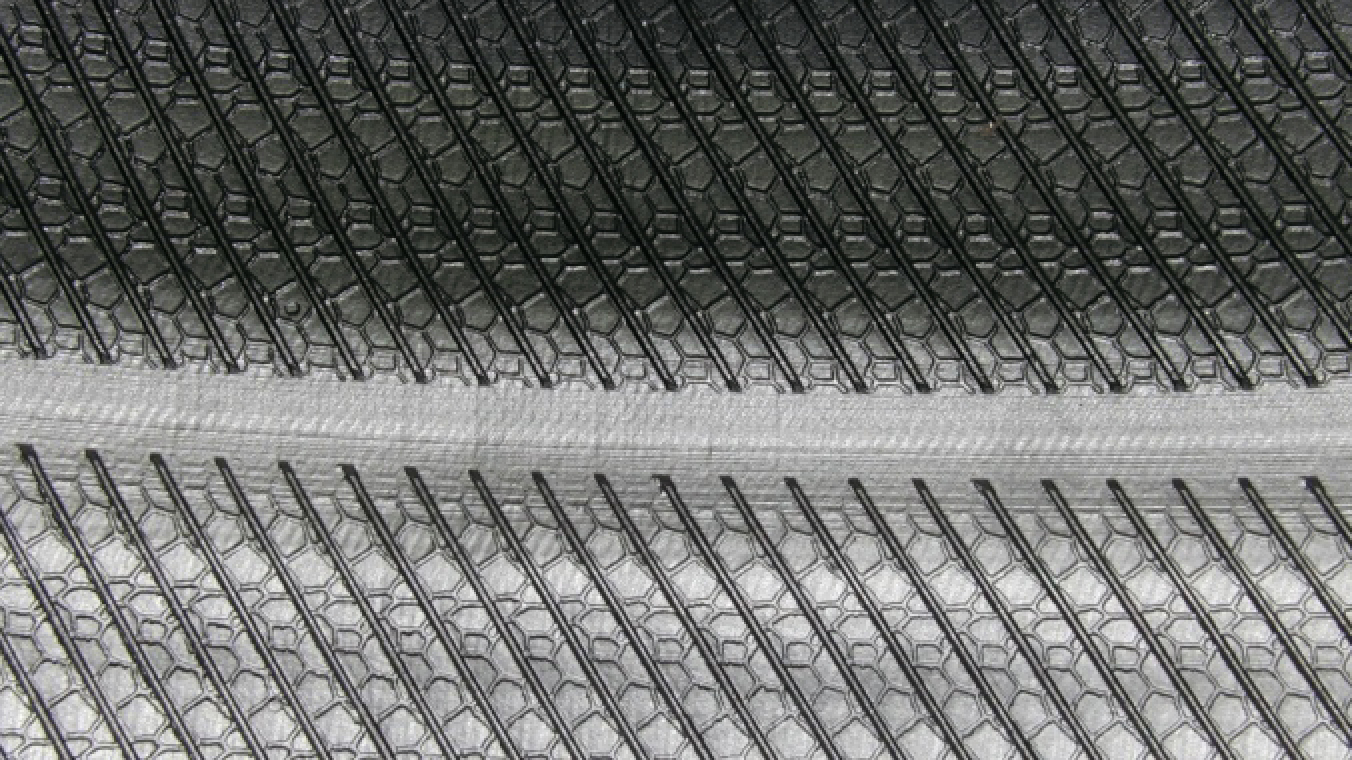

Tire Inner Liner Laser Cleaning

Superior in quality to mechanical or chemistry-based processes, laser cleaning removes release agents and oil residues from the tire inner liner without touching the tire and with a significantly lower carbon and installation footprint in your factory. Our groundbreaking and IP protected Helix processes guarantee best in class cycle-times and hence cost per tire while maintaining superior cleaning results based on high peak-pulse-energy lasers.

Tire Inner Liner Laser Cleaning TCS Silent Tires LASER-FIT Line

Laser Tire Uniformity Correction

Selective, precise and traceless laser ablation of material from a tire´s bead area allows to improve the tire uniformity parameters. Ablation area and patterns are automatically generated based on the tire´s TU data. Other than mechanical grinding the process is clean, causes no tool wear, and leaves a smooth surface. The technology has seen significant industrial adaption in the last years under an exclusive supply agreement and is now commercially available to any tire manufacturer.

Discover how our laser systems can elevate your tire production –

from marking and traceability to foam application, mold and inner liner cleaning, or uniformity correction.

Enabling Capabilities Across All Tire Applications

Our solutions for the tire industry are designed for precision, repeatability, and industrial scalability, and are complemented by cross-functional capabilities that add long-term value, operational reliability, and digital readiness to all applications.

Core4 Software Platform

At the heart of every 4JET tire system is Core4 — our scalable, industrial-grade software backbone.

- Intuitive UI/UX for operator-friendly handling in tire production environments

- AI-powered vision for tire code reading, pattern validation, and defect detection

- Integrated PLC sequencing, recipe management, and production data logging

- Backed by a 20+ developer team ensuring reliability and rapid feature deployment